Method of manufacturing surface textured high-efficiency radiating devices and devices obtained therefrom

a technology of radiating devices and surface textured, which is applied in the direction of optics, instruments, optical elements, etc., can solve the problems of reducing the efficiency of the total light emission of the device, the device is not suitable for integration in large arrays, and the device is inherently slow, so as to reduce the recombination effect of charge carriers, improve the efficiency and the speed of the device, and reduce the surface recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

For the purpose of teaching of the invention, preferred embodiments of the method and devices of the invention are described in the sequel. It will be apparent to the person skilled in the art that other alternative and equivalent embodiments of the invention can be conceived and reduced to practice without departing form the true spirit of the invention, the scope of the invention being limited only by the appended claims.

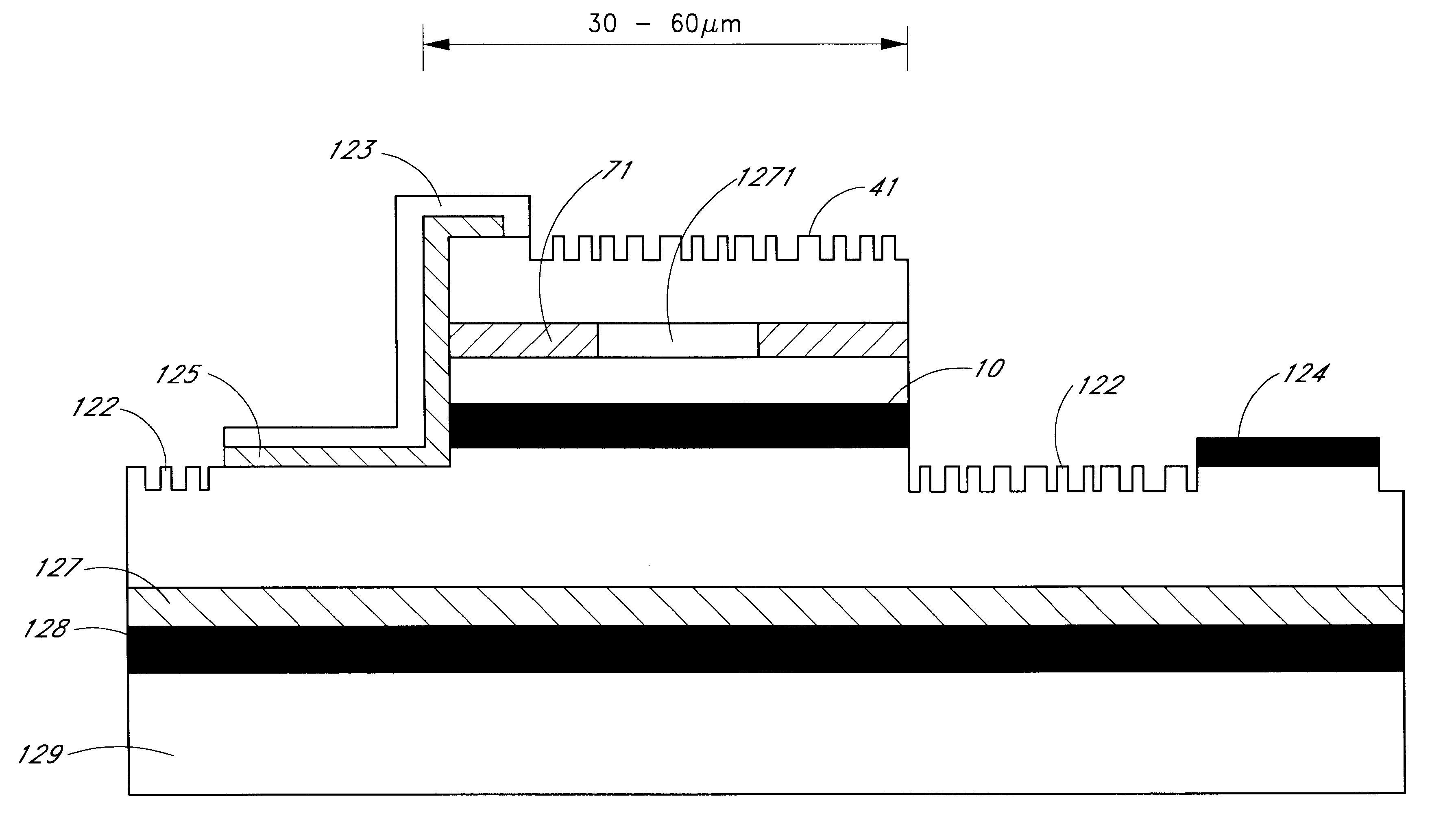

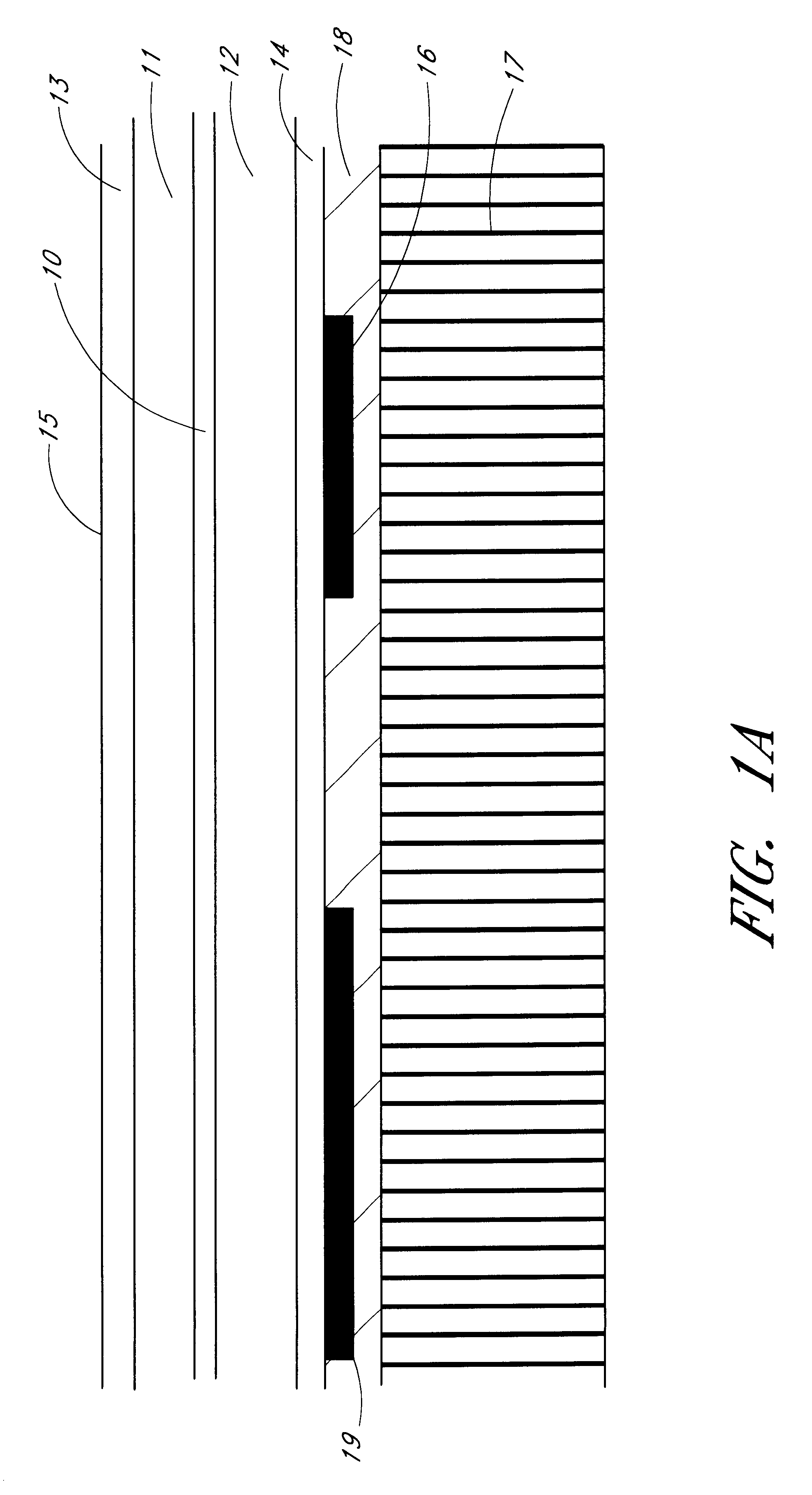

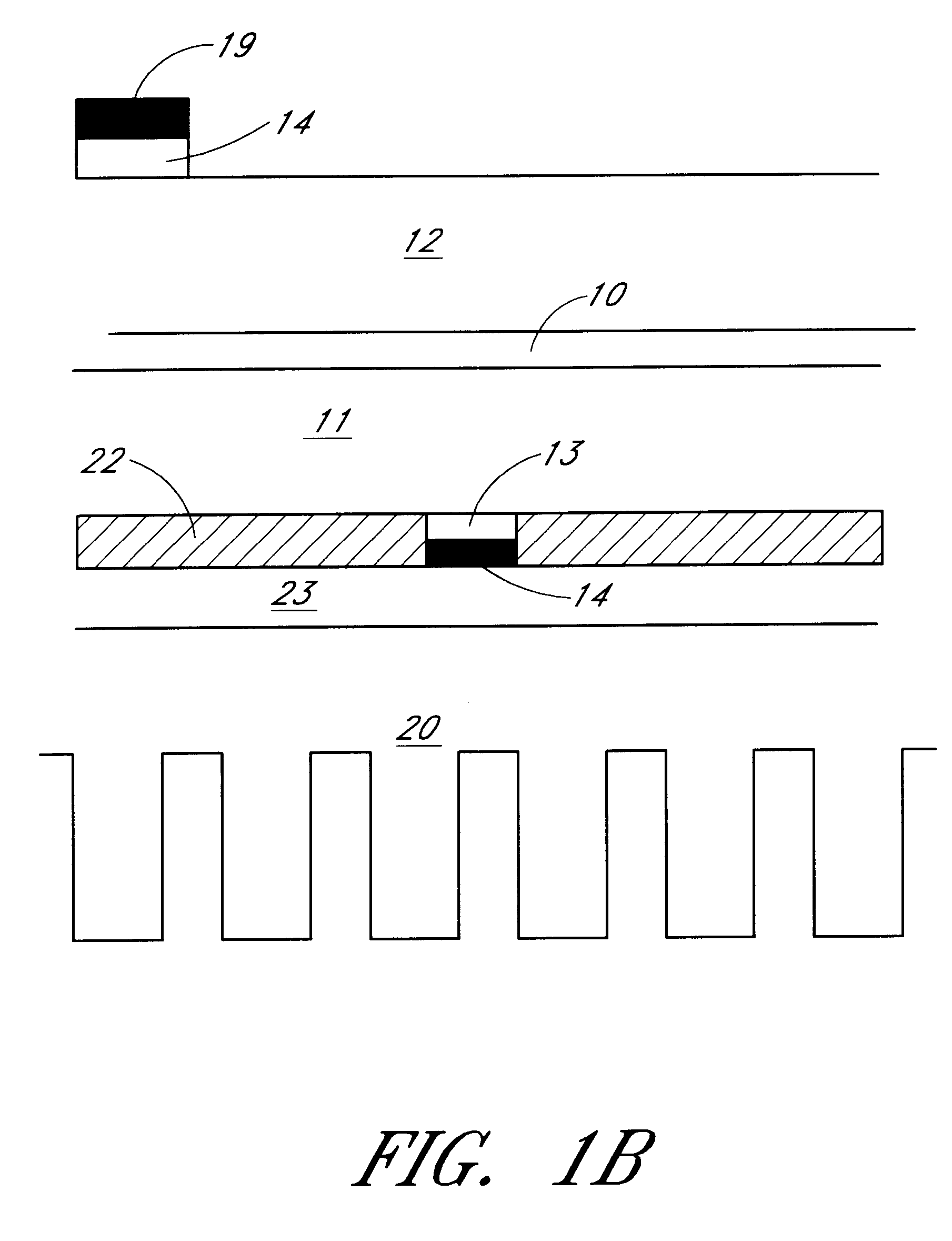

FIG. 1a shows the layer structure of a light-emitting diode (LED) according to an embodiment of a device of the present invention. This layer structure will be assumed for the devices disclosed in this detailed description of the invention. A layer structure is shown and the layers are made in semiconductor material, preferably III-V semiconductor material and the different layers can be made of different semiconductors. The layers can be epitaxially grown or can be deposited on a substrate. The substrate whereon the layers are made is removed and the layer struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com