Method and flow system for spectrometry and a cuvette for the flow system

a flow system and flow system technology, applied in the direction of material testing goods, testing food, instruments, etc., can solve the problems of dissolved air, measurement results that will obviously not show the correct analysis of milk products themselves, thin milk layers tend to adhere to the ir-windows of the cuvette, etc., to achieve optimal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

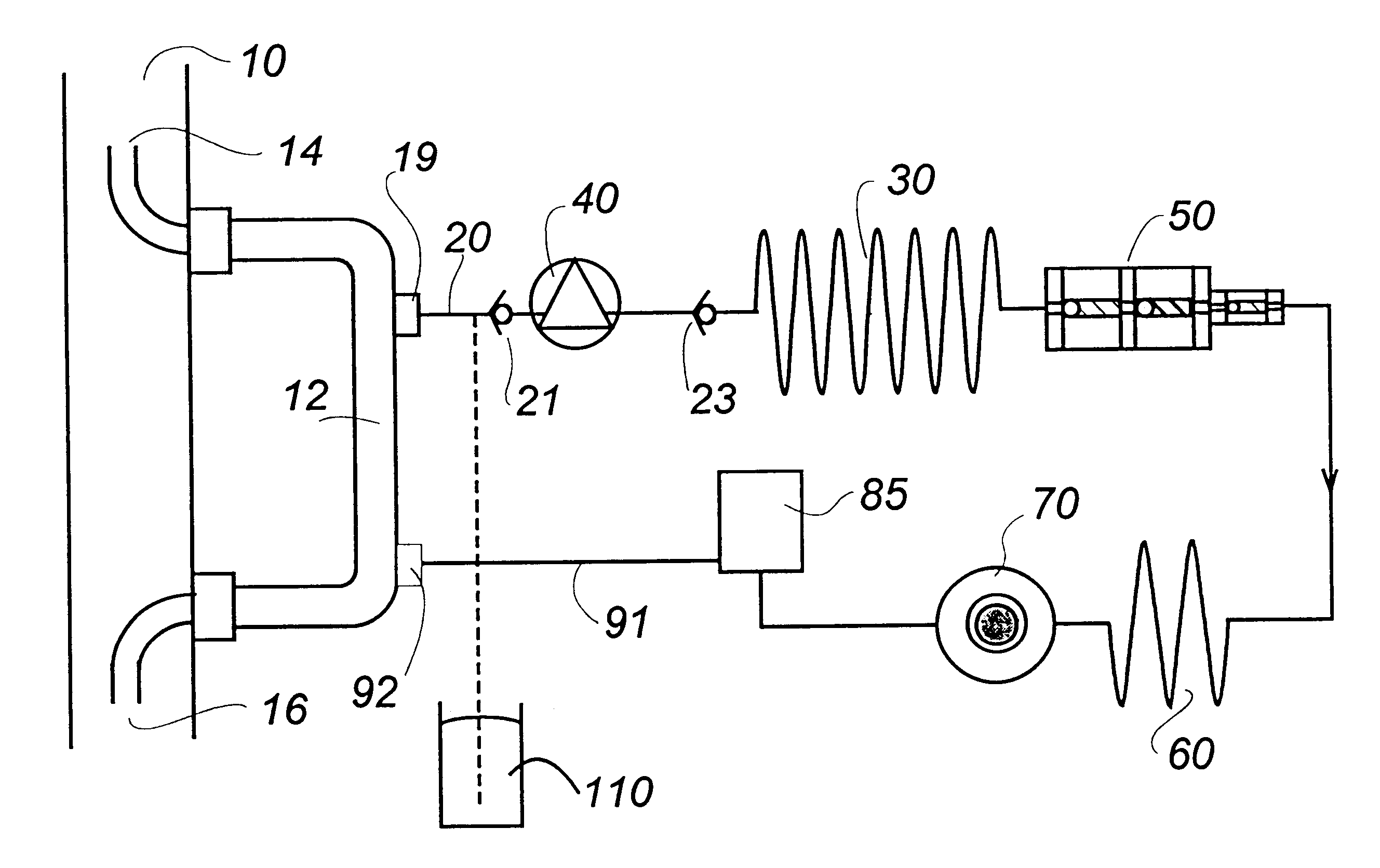

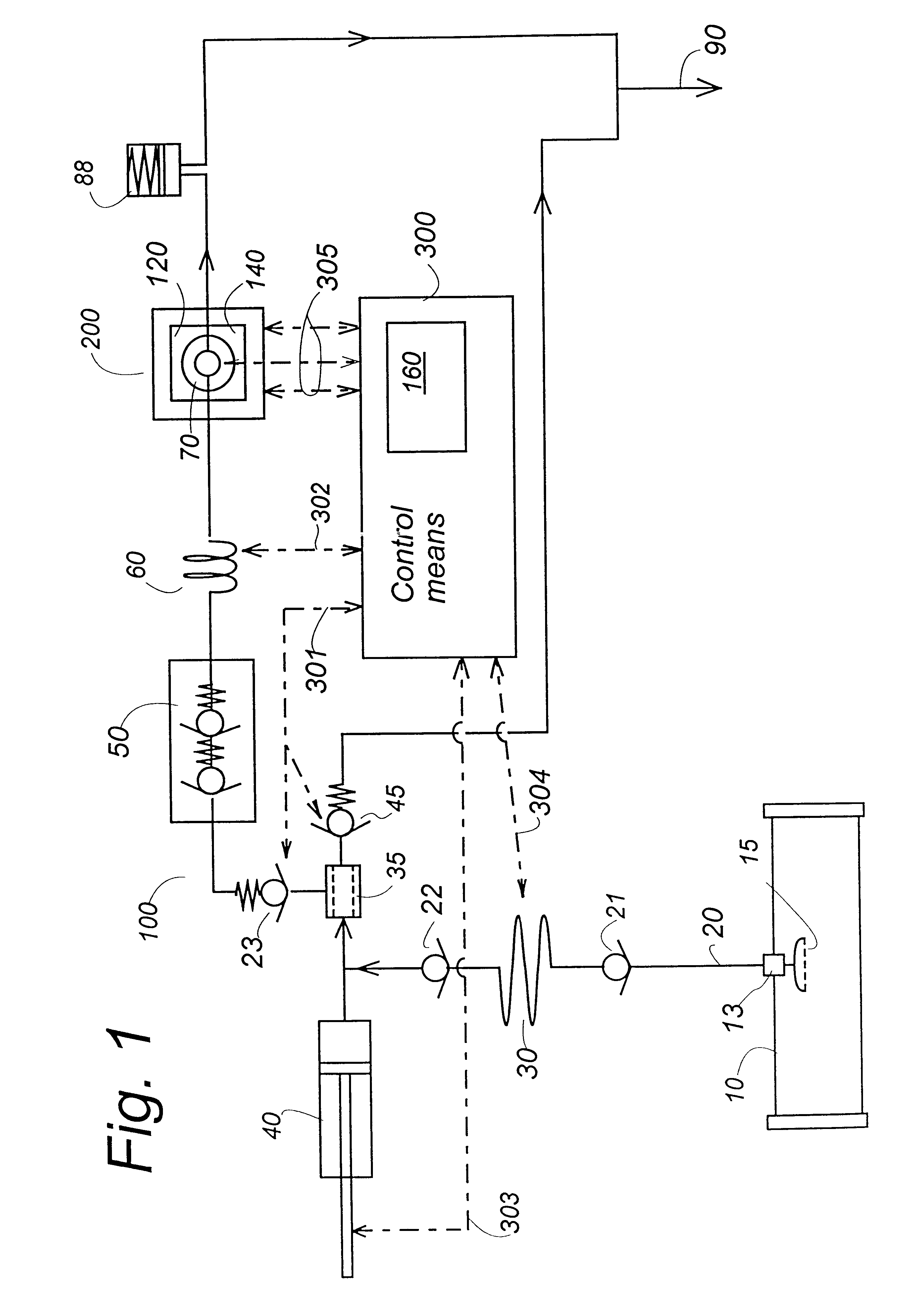

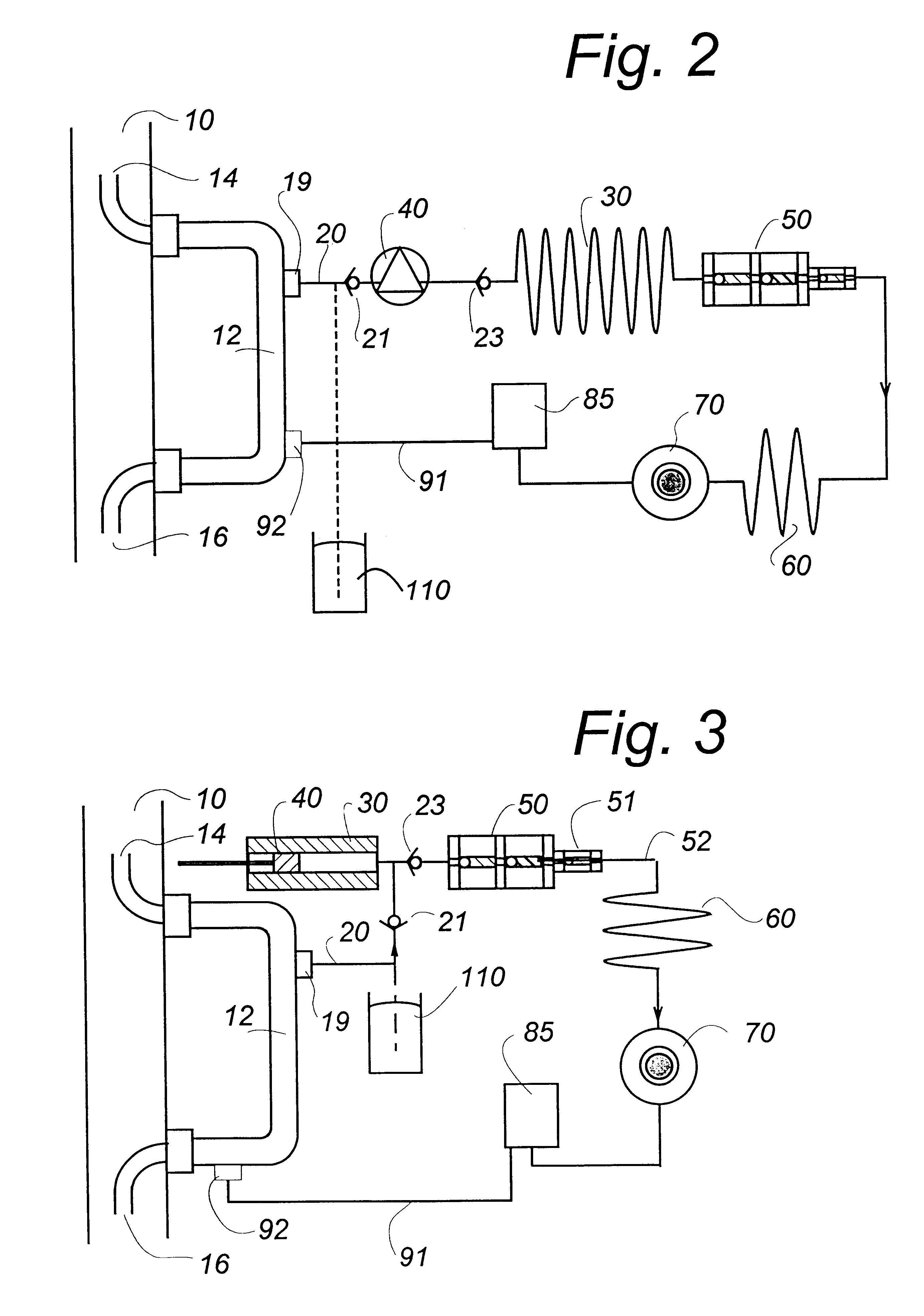

In a second embodiment shown in FIG. 2 the flow system comprises: a fast-loop, i.e. an U-formed tube 12 having an inlet 14 and an outlet 16 arranged inside a process conduit 10 which is part of a process plant such as a dairy, which is not shown in the drawings. The is fast-loop tube 12 is small compared to the process conduit 10. Typically the inner diameter of the fast loop is about 10 mm in a process conduit 10 having an inner diameter of about 70 mm. The drawing does not show the true dimensions.

The inlet 14 opens towards the direction of the process flow in the conduit 10, in such a way that a fraction of the process flow is diverted through the fast-loop. At the outlet 16 the process flow will generate suction, forcing the diverted flow to return into the process conduit 10.

A sample intake is provided by a tiny flexible tube 20, having an inlet opening with filter communicating with the fast-loop through a detachable connection e.g. so-called mini clamps 19 comprising two flan...

third embodiment

By the embodiment shown in FIG.3 the pump 40 is a single stroke pump surrounded by heating means, e.g. a coil. The method is carried out as follows: In a first step of about two sec's a sample is sucked into the pump cylinder by one suction stroke of the piston. Then in a second step the sample is heated inside the pump cylinder for about 25 secs. In a third preferably short step of about 0.5-1.0 sec. duration the piston stroke is reversed, pushing the new sample through the homogenizer and partly through the cuvette and the back pressure valve. Thereby the old sample is flushed away either into a waste outlet 90 or returned into the fast loop and the process conduit If the third step is performed in 0.5 sec. the flushing rate through the cuvette will be about 10-30 m / s with a displaced milk volume of about 1.5 ml. This flushing rate will ensure a thorough cleaning of the cuvette windows between each measurement. The advantage of the third embodiment is that the suction stroke may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com