Method for manufacturing thermoplastic resin composition

a technology of thermoplastic resin and composition, which is applied in the field of thermoplastic resin composition manufacturing, can solve the problems of large dangers of strong acidic solution, large load on the environment, and eroded three-dimensional objects in the precursor of three-dimensional objects, and achieves the effects of reducing the use of polyester resin, and reducing the risk of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

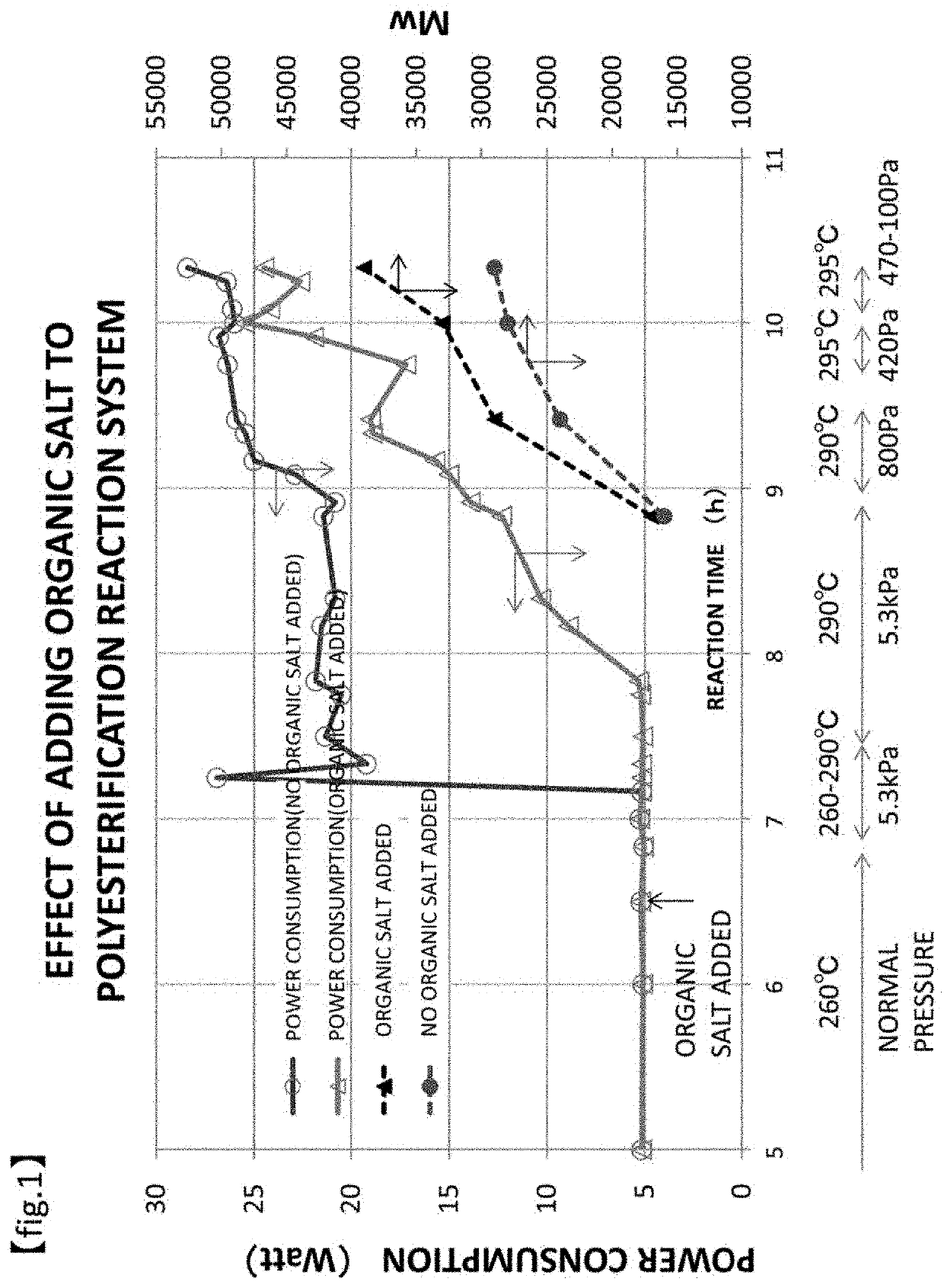

[0254]In a 2-L stainless steel separable flask (equipped with a K-tube, a stirrer, and a nitrogen introducing tube) were prepared 97.7 g of dimethyl 2,6-naphthalenedicarboxylate (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), 40.6 g of sodium dimethyl 5-sulfoisophthalate (manufactured by Wako Pure Chemical Industries, Ltd.), 76.7 g of ethylene glycol (manufactured by Wako Pure Chemical Industries, Ltd., special grade), 82 mg of titanium tetrabutoxide (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), and 506 mg of sodium acetate (manufactured by Wako Pure Chemical Industries, Ltd., special grade). Then, the mixture was heated by a mantle heater, with the outside temperature increased from 140° C. to 260° C. over 1 hour, under stirring at normal pressure under a nitrogen atmosphere, and was stirred at that temperature for 6.5 hours to undergo a transesterification reaction. Thereafter, 6.89 g of tetrabutylphosphonium dodecylbenzenesulfonate (manufactu...

example 2

[0256]In a 2-L stainless steel separable flask (equipped with a K-tube, a stirrer, and a nitrogen introducing tube) were prepared 23.7 g of dimethyl 2,6-naphthalenedicarboxylate (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), 52.1 g of sodium dimethyl 5-sulfoisophthalate (manufactured by Wako Pure Chemical Industries, Ltd.), 22.4 g of ethylene glycol (manufactured by Wako Pure Chemical Industries, Ltd., special grade), 26 mg of titanium tetrabutoxide (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), 117.3 g of bisphenoxyethanolfluorene (manufactured by Osaka Gas Chemicals Co., Ltd.), and 866 mg of sodium acetate (manufactured by Wako Pure Chemical Industries, Ltd., special grade). Then, the mixture was heated by a mantle heater, with the outside temperature increased from 180° C. to 260° C. over 1 hour and 10 minutes, under stirring at normal pressure under a nitrogen atmosphere, and was stirred at that temperature for 4 hours and 20 minutes to unde...

example 3

[0257]In a 2-L stainless steel separable flask (equipped with a K-tube, a stirrer, and a nitrogen introducing tube) were prepared 23.7 g of dimethyl 2,6-naphthalenedicarboxylate (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), 52.1 g of sodium dimethyl 5-sulfoisophthalate (manufactured by Wako Pure Chemical Industries, Ltd.), 22.4 g of ethylene glycol (manufactured by Wako Pure Chemical Industries, Ltd., special grade), 26 mg of titanium tetrabutoxide (manufactured by Tokyo Chemical Industry Co., Ltd., first grade), 117.3 g of bisphenoxyethanolfluorene (manufactured by Osaka Gas Chemicals Co., Ltd.), and 866 mg of sodium acetate (manufactured by Wako Pure Chemical Industries, Ltd., special grade). Then, the mixture was heated by a mantle heater, with the outside temperature increased from 180° C. to 260° C. over 1 hour, under stirring at normal pressure under a nitrogen atmosphere, and was stirred at that temperature for 4 hours to undergo a transesterification reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass ratio | aaaaa | aaaaa |

| mass ratio | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com