Method for changing the colour of a textile, fabric and garment

a technology for textiles and fabrics, applied in the field of textile finishing, can solve the problems of high health risks, high sanding risk, and wet washing process, and achieve the effects of less harmful to the environment, less time, and enhanced colour fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

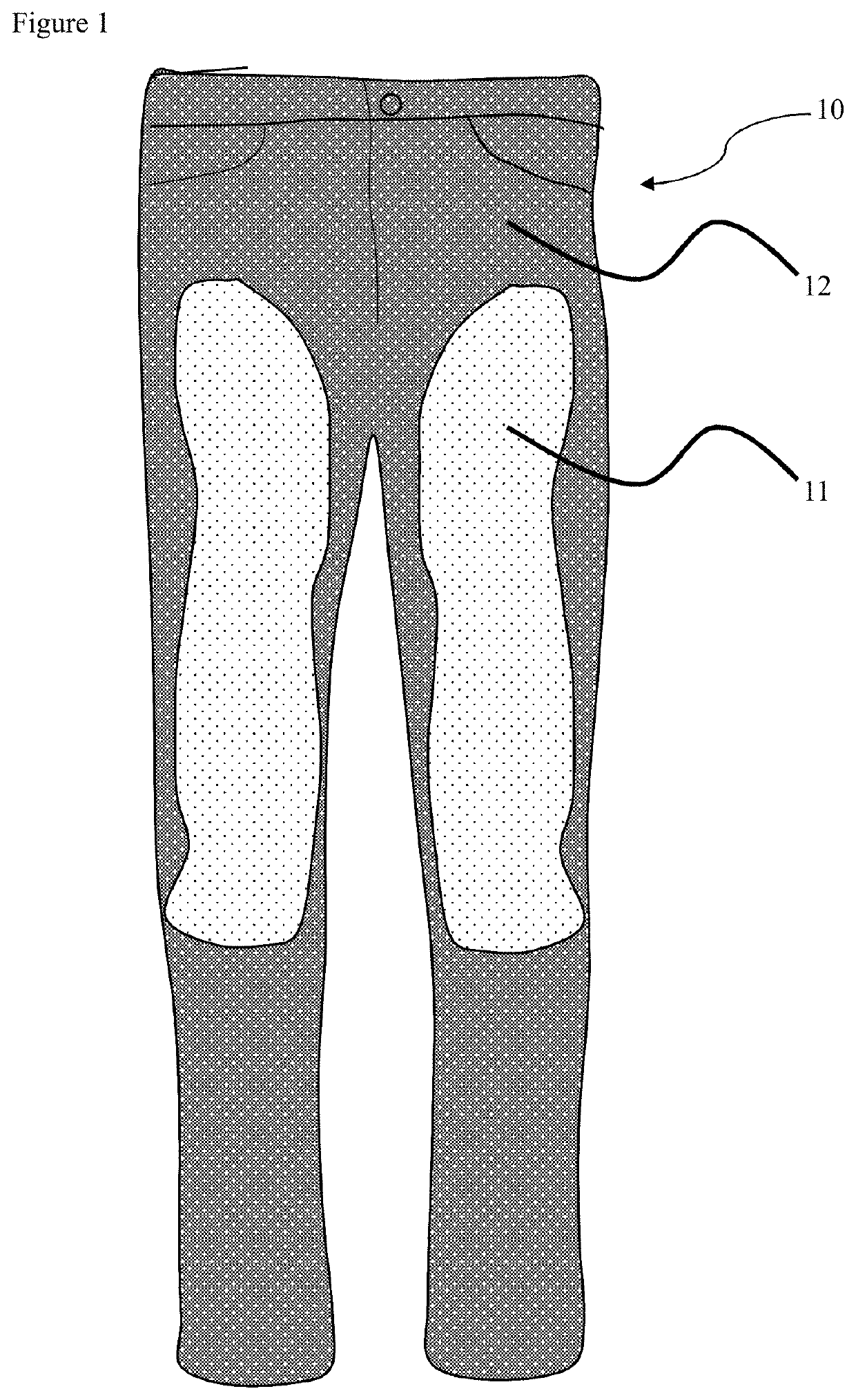

Image

Examples

example 2

[0061]Comparative Example of Change in Colour

[0062]A fabric of the invention is prepared according to steps a), a′), b) and c) as disclosed in Example 1.

[0063]A comparative fabric is prepared by carrying out laser treatment using the same parameters disclosed in Example 1 starting from an identical fabric as the one of Example 1. The comparative fabric has not been subjected to steps a), a′) and b) of the method of the invention.

[0064]The change in colour of the fabrics is evaluated by Datacolor 6000 spectrophotometer using the strength adjustment method, which is a conventional method for comparing the strength of colours. Max absorption peak is set at 660 nm. Fix adjustment strength is set to 100%. The comparative fabric shows a result of 100% strength. The fabric of the invention shows a result of 52% strength. According to the above results, the fabric of the invention has less colour strength compared to the comparative fabric, therefore a higher colour fading is obtained with ...

example 3

[0066]Energy and Time Saving of the Method of the Invention

[0067]A comparative fabric and a fabric of the invention have been prepared starting from identical untreated fabrics. The comparative fabric has been prepared carrying out only laser treatment on the untreated fabric.

[0068]It has been observed by the present Example that the laser treatment to manufacture the fabric of the invention provided an energy saving of about 12% to 20% and a time saving of about 12% to 15% per garment, in particular per pair of pants, and an energy saving of about 120 to 130 W and of about 86 seconds per m2 of treated fabric, with respect to the laser treatment to manufacture the comparative fabric, to provide a comparable vintage look.

[0069]The present Example proves that the laser treatment (step c)) of the method of the invention, compared to laser treatment only, (i) provides cost-savings in terms of energy-savings and time-savings, and (ii) can be carried out with reduced values of the operati...

example 4

[0070]The method of the invention is carried out on a fabric. 5 g of such fabric are kept in 200 mL of deionized water for 30 minutes at a temperature of 50° C. Then, complexometric titration is carried out on the water above using EDTA. It resulted that such water contained 5.8 mg / L of magnesium ion corresponding to about 62 mg / L of magnesium nitrate hexahydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com