Collagen material and method for producing collagen material

a technology of collagen material and collagen material, which is applied in the direction of macromolecular non-active ingredients, pharmaceutical delivery mechanisms, prosthesis, etc., can solve the problems of not being able to design a collagen material shape and the orientation of the material freely, and not being able to freely set the direction of the material orientation, etc., to achieve the effect of convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0094]In a method of the present invention, first of all, a collagen gel was prepared as an orientated collagen (substrate) having a size of a millimeter order or more. As to a collagen gel, 9.3 mg / mL concentration of I type of collagen solution derived from a rat tail (BD Company) was extruded through a nozzle having 0.38 mm of an inside diameter into a plate container containing a phosphate buffered saline (PBS) at 38° C., at pH7.4, and thereby sliding the nozzle to obtain a string like collagen gel having about 1 mm in diameter, about 20 mm of length.

[0095]An orientation of a collagen gel obtained thus was analyzed by a raman spectroscopic microscope (PHOTON Design Corporation). In doing so, an excitation wavelength was set at 514.5 nm using a continuous oscillation argon ion laser Stabilite 2017 (Spectra-Physics, Inc.), a HR-320 (Jovin Yvon S.A.S.) as a spectroscope and a LN / CCD-1100-PB / UV AR / 1 (Roper scientific Inc.) were used respectively. FIG. 5 gives a result of evaluating a...

example 2

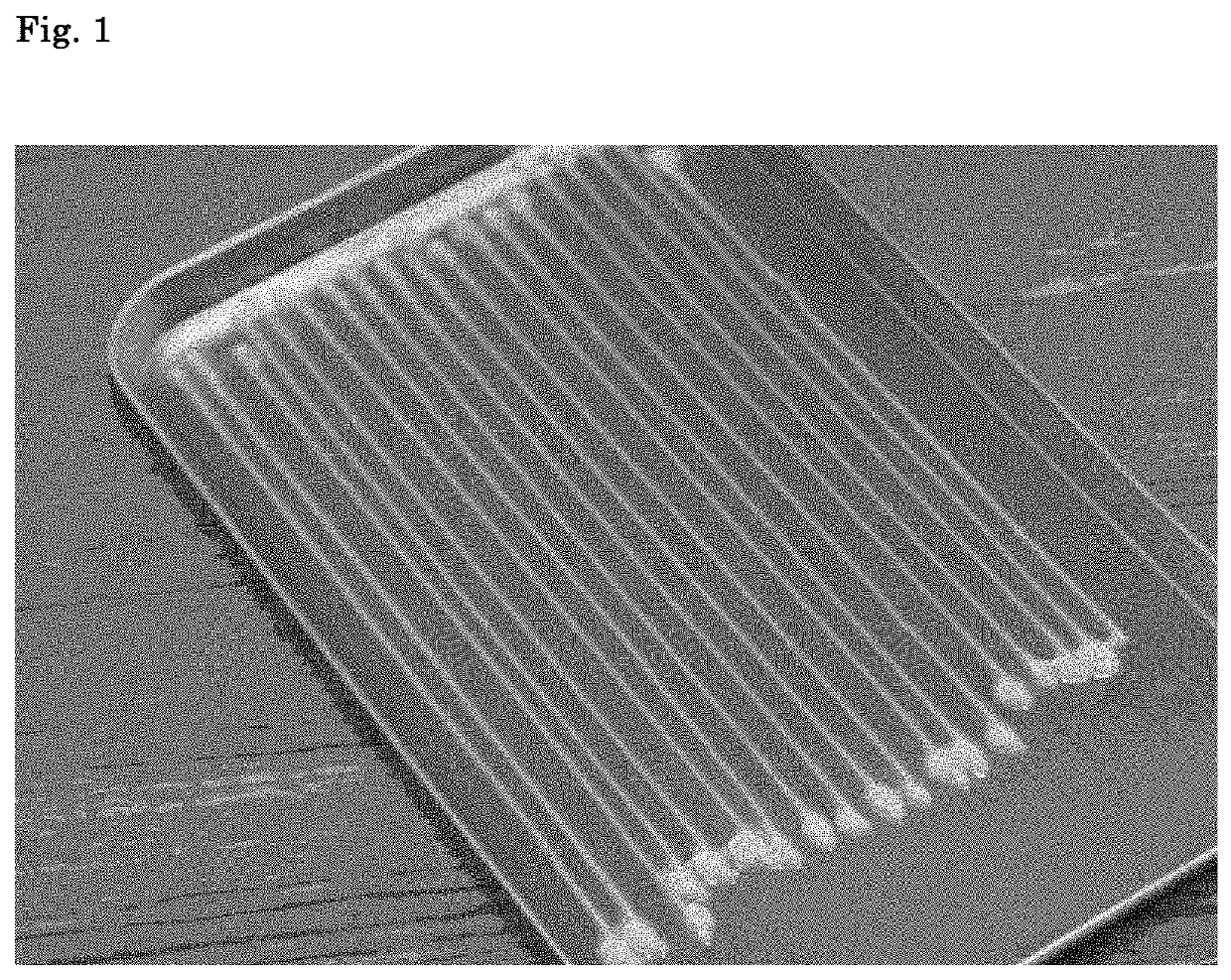

[0096]Next, a larger size of the collagen material is tried to obtain. First of all, a orientated collagen gel with a string shape was prepared. As to a collagen gel, 9.3 mg / mL concentration of I type of collagen solution derived from a rat tail (BD Company) was extruded through a nozzle having 0.38 mm of an inside diameter into a plate container containing a phosphate buffered saline (PBS) at 38° C., at pH7.4, and thereby sliding the nozzle to obtain a string like collagen gel having about 1 mm in diameter, about 200 mm of length. FIG. 1 gives a photograph of an orientated collagen gel with a string shape immediately after it is produced in PBS.

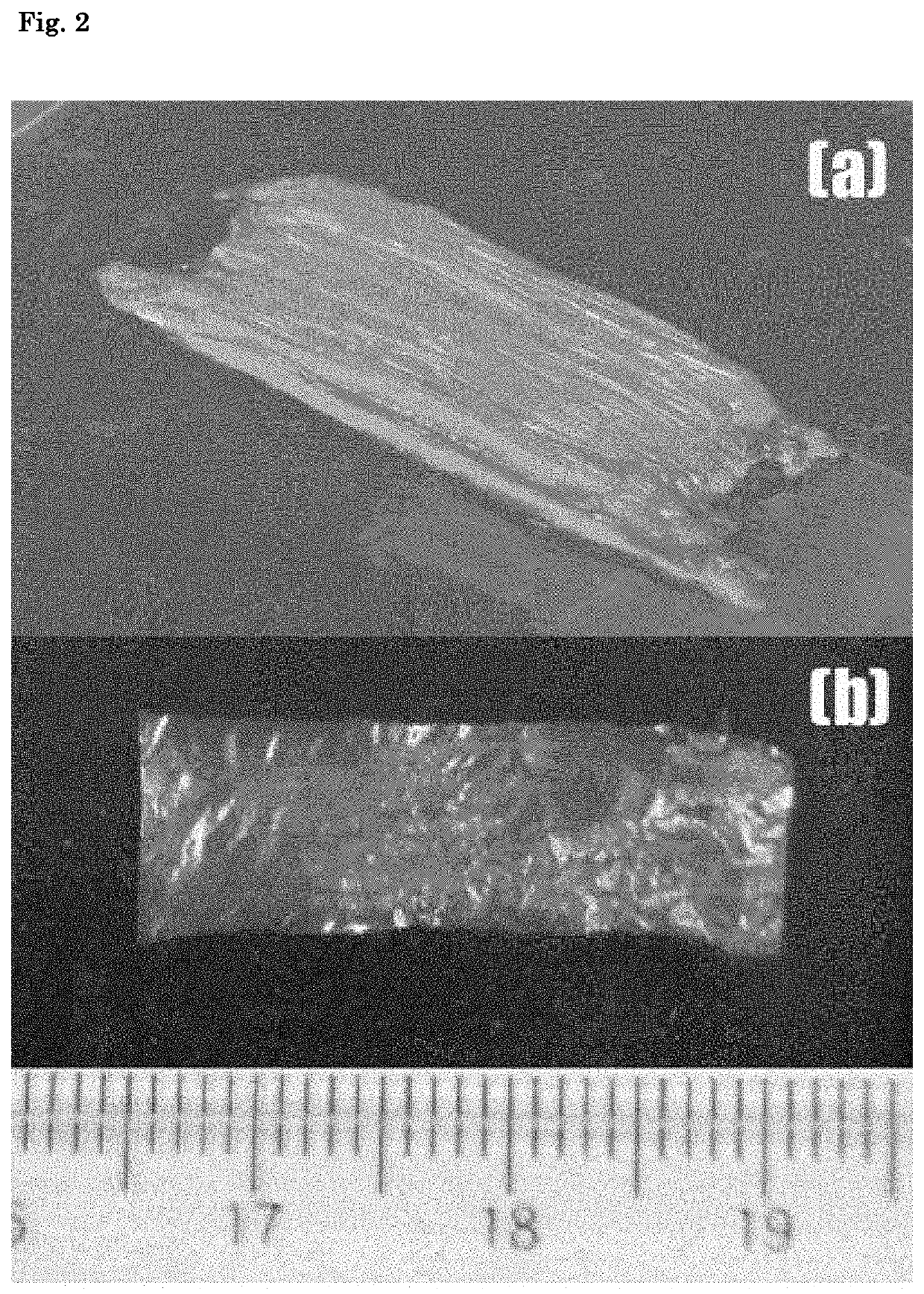

[0097]The produced orientated collagen gel with a string shape is aligned on a plane as shown in FIG. 2, and after that is dried to obtain a dried orientated collagen material with a sheet shape.

example 3

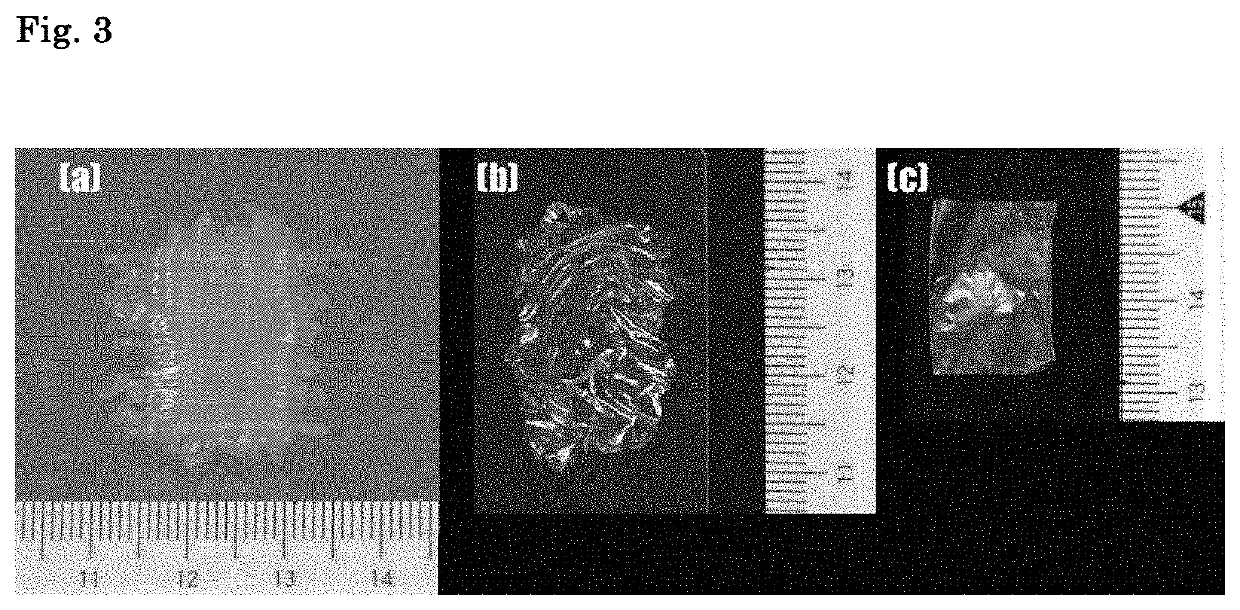

[0098]The above mentioned orientated collagen gel with a string is aligned on the plane with a sheet shape. After that, a second layer is aligned wherein a direction of an orientated collagen gel with a string shape is perpendicular to a travel direction of the orientated collagen with a string shape of the first layer (FIG. 3(a)). After that, a dried sample is shown in FIG. 3(b), a sample cut in rectangles after drying is shown in FIG. 3(c). In this way, it is possible to make not only single layer but multiple layers using the orientated collagen sheet with a sheet shape, and further it is possible to freely design a direction of orientation of each layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com