Method for manufacturing secondary battery and secondary battery using same

a secondary battery and manufacturing method technology, applied in sustainable manufacturing/processing, cell components, wound/folded electrode electrodes, etc., can solve the problems of secondary battery defect, deterioration of cutting quality, and frequent maintenance and repair work of cutting using molds, so as to reduce the occurrence of electrical shorts, prevent contamination, and improve the quality of the cut surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problems to be Solved

[0005]The present invention provides a method for manufacturing a secondary battery and a secondary battery using the same, which can improve the quality of a cut surface of an electrode plate and improve the reliability of the secondary battery.

Technical Solutions

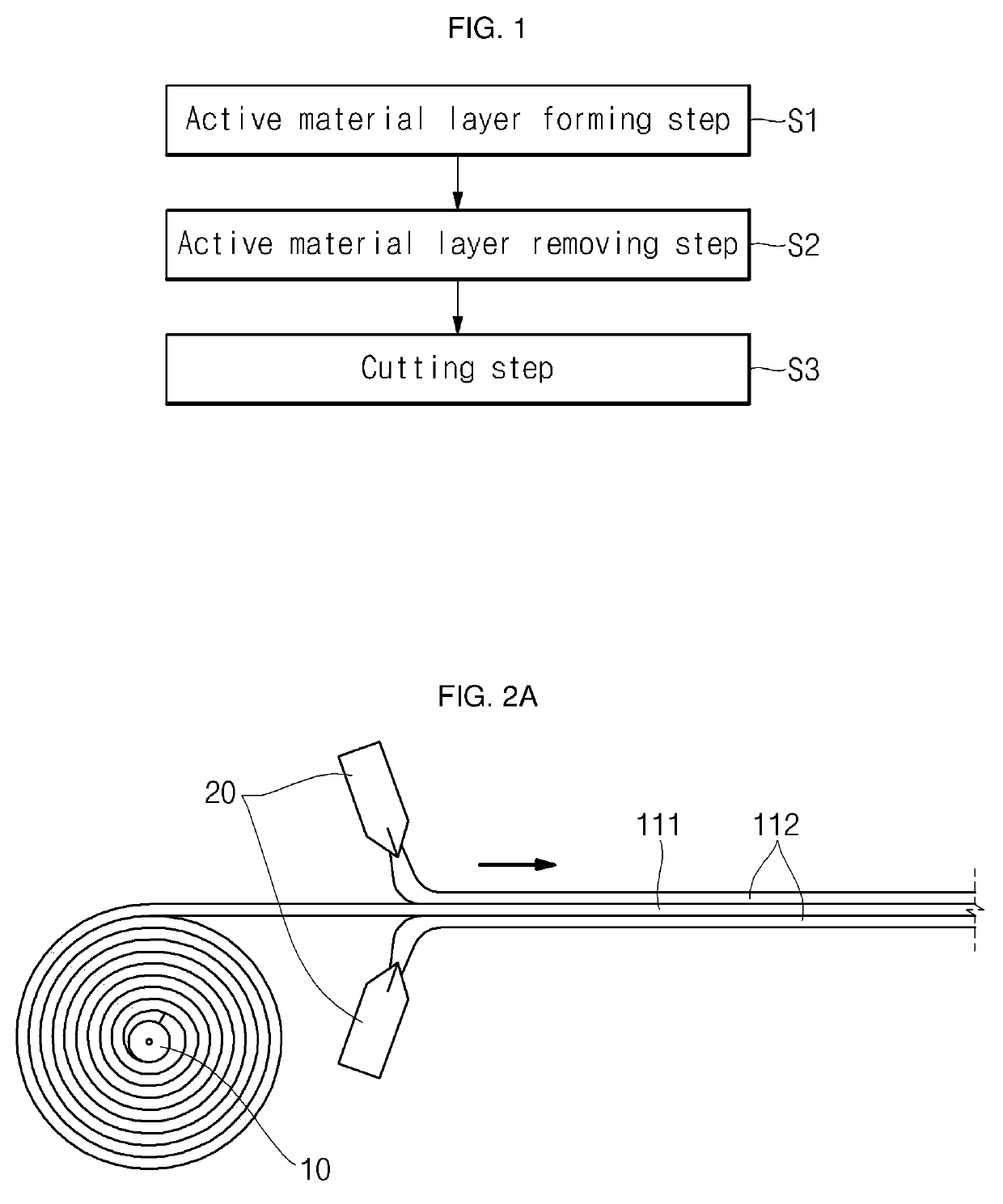

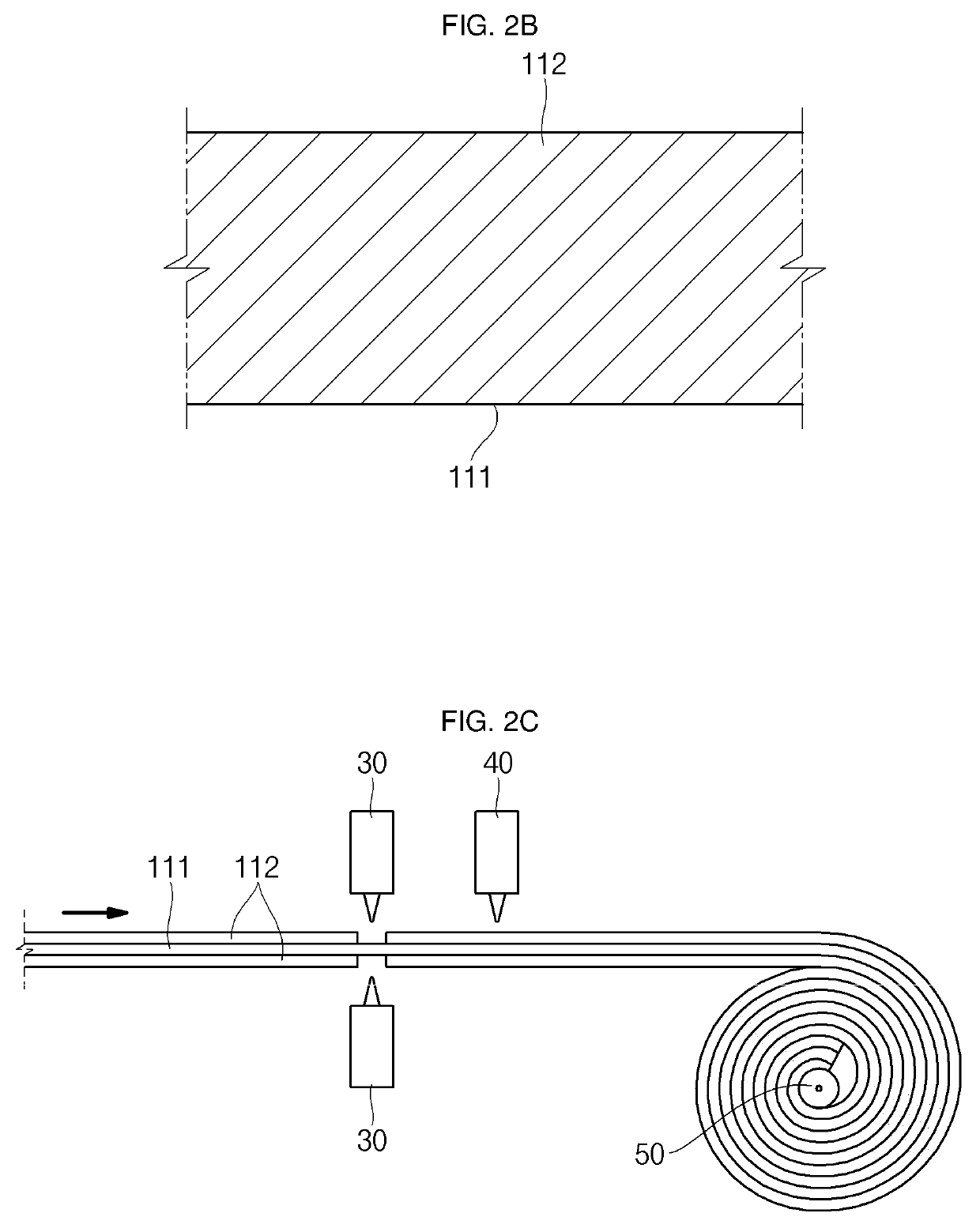

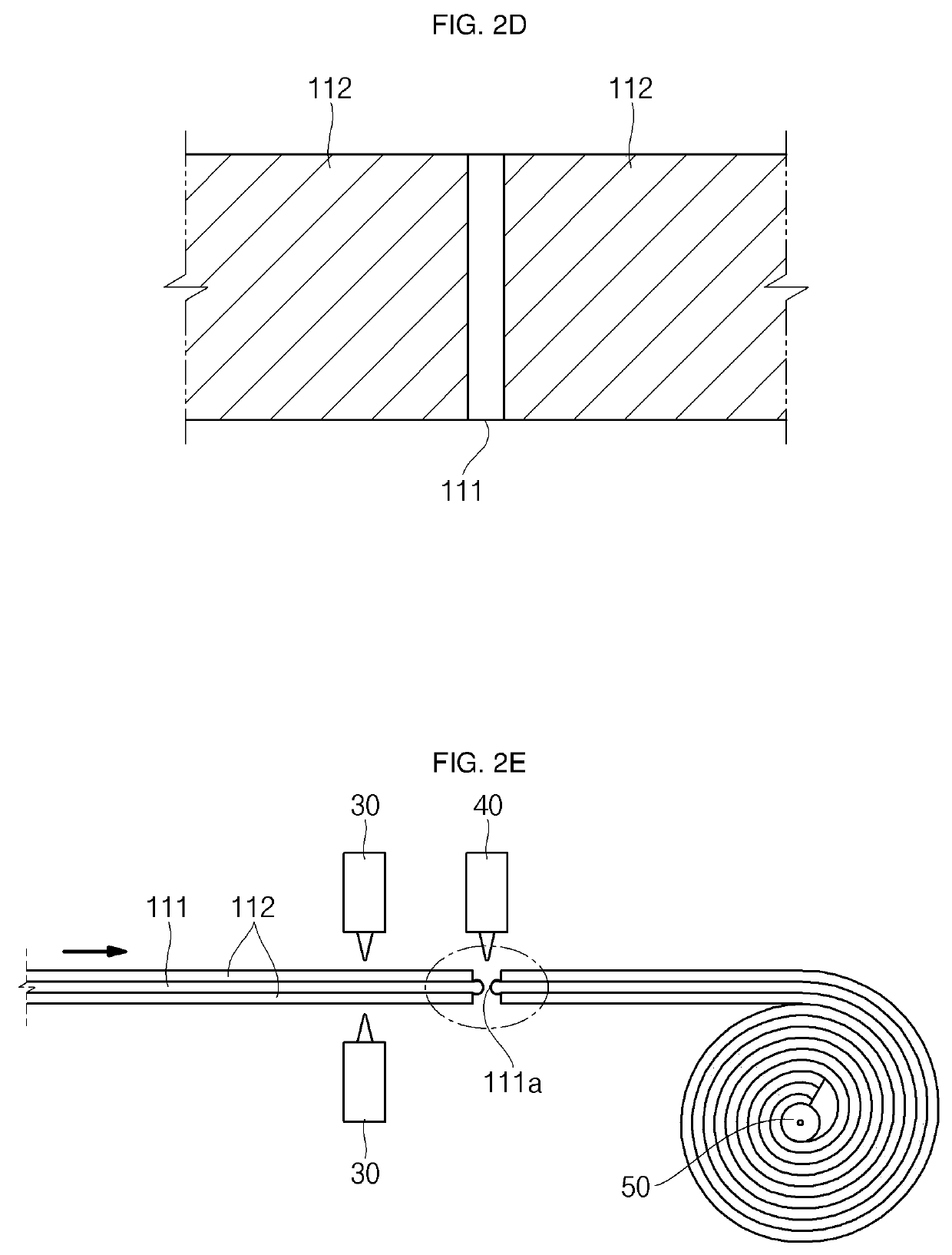

[0006]In an exemplary embodiment of the present invention, there is provided a method for manufacturing a secondary battery, the method including an active material layer forming step of forming an active material layer by coating an active material on both surfaces of a collector plate, an active material layer removing step of removing a part of the active material layer by irradiating a laser beam to the both surfaces of the collector plate, and a cutting step of cutting the collector plate by irradiating a laser beam onto the collector plate from which the active material layer has been removed in the active material layer removing step.

[0007]The laser beam irradiated in the active materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com