Road basket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

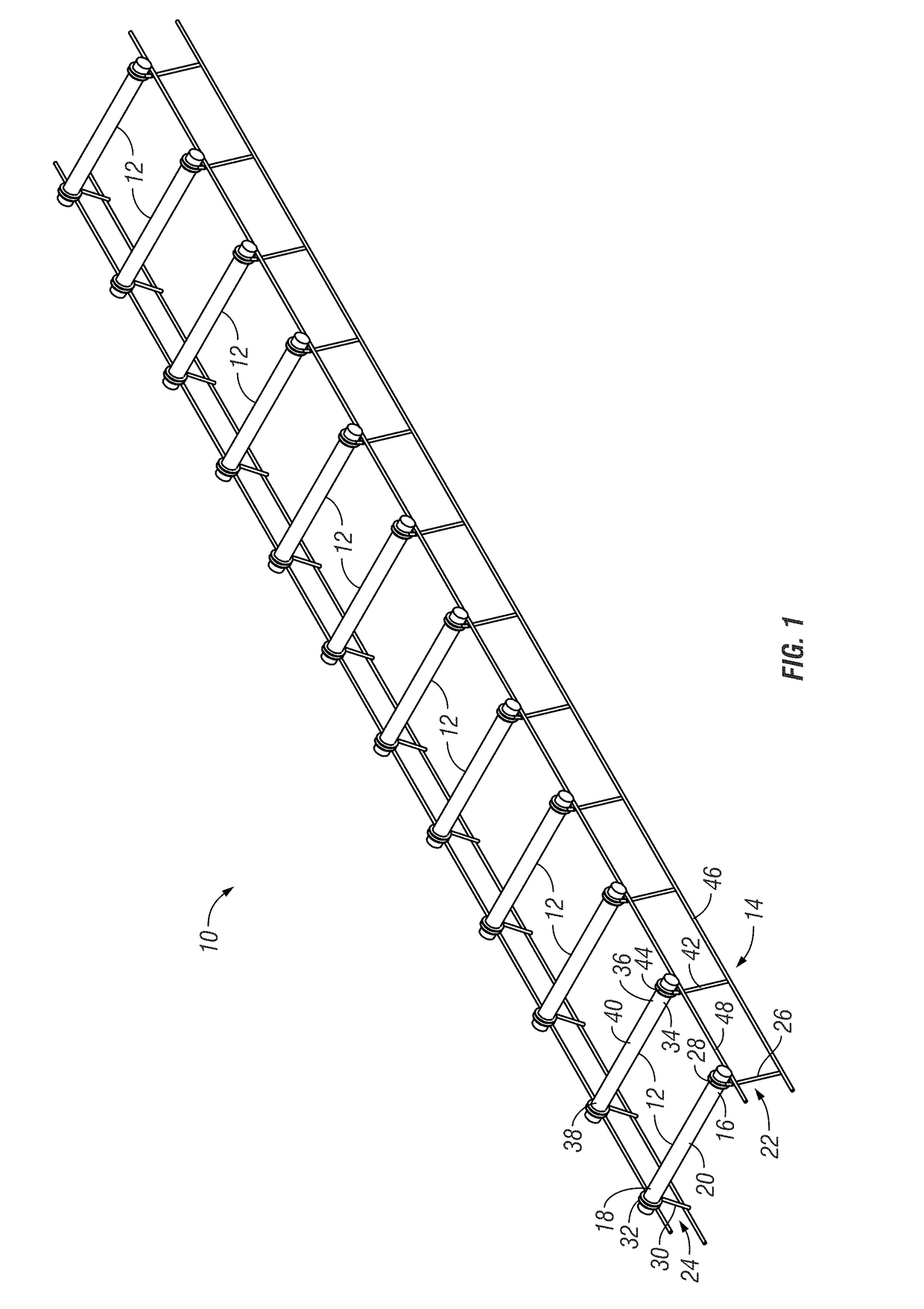

[0030]An apparatus and system for securing a reinforcing dowel as part of a road basket for use with concrete and other masonry or cementitious materials is disclosed. The road basket may be used to reinforce poured concrete slabs, such as paved roads and bridges. For example, the road basket may be placed within the area where a concrete slab is to be poured for a roadway. The road basket may be configured to secure a dowel at a preferred location, such as height or depth, to provide improved structural properties for the concrete structure.

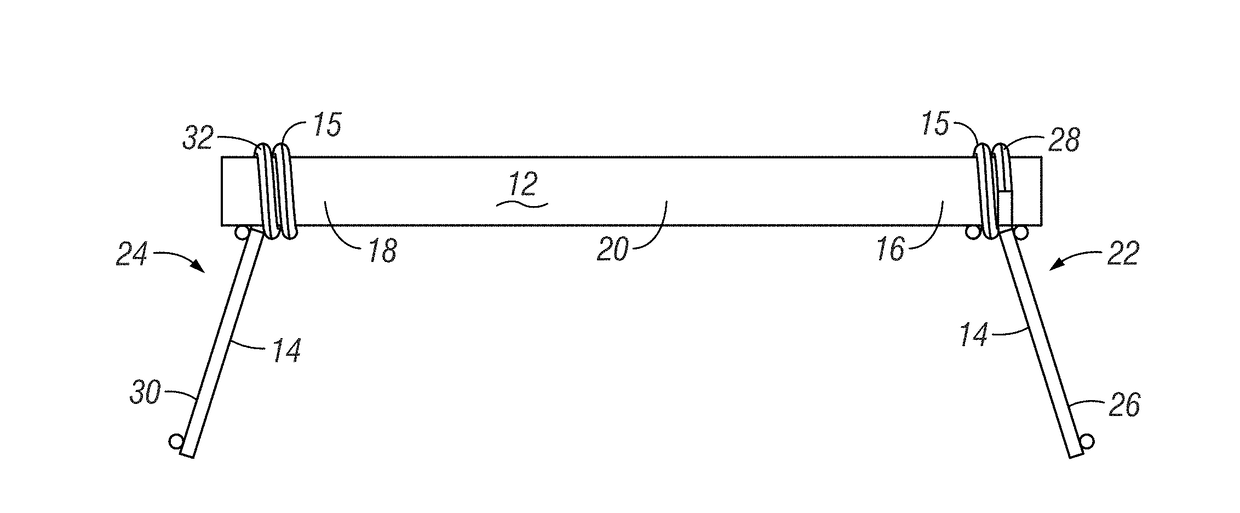

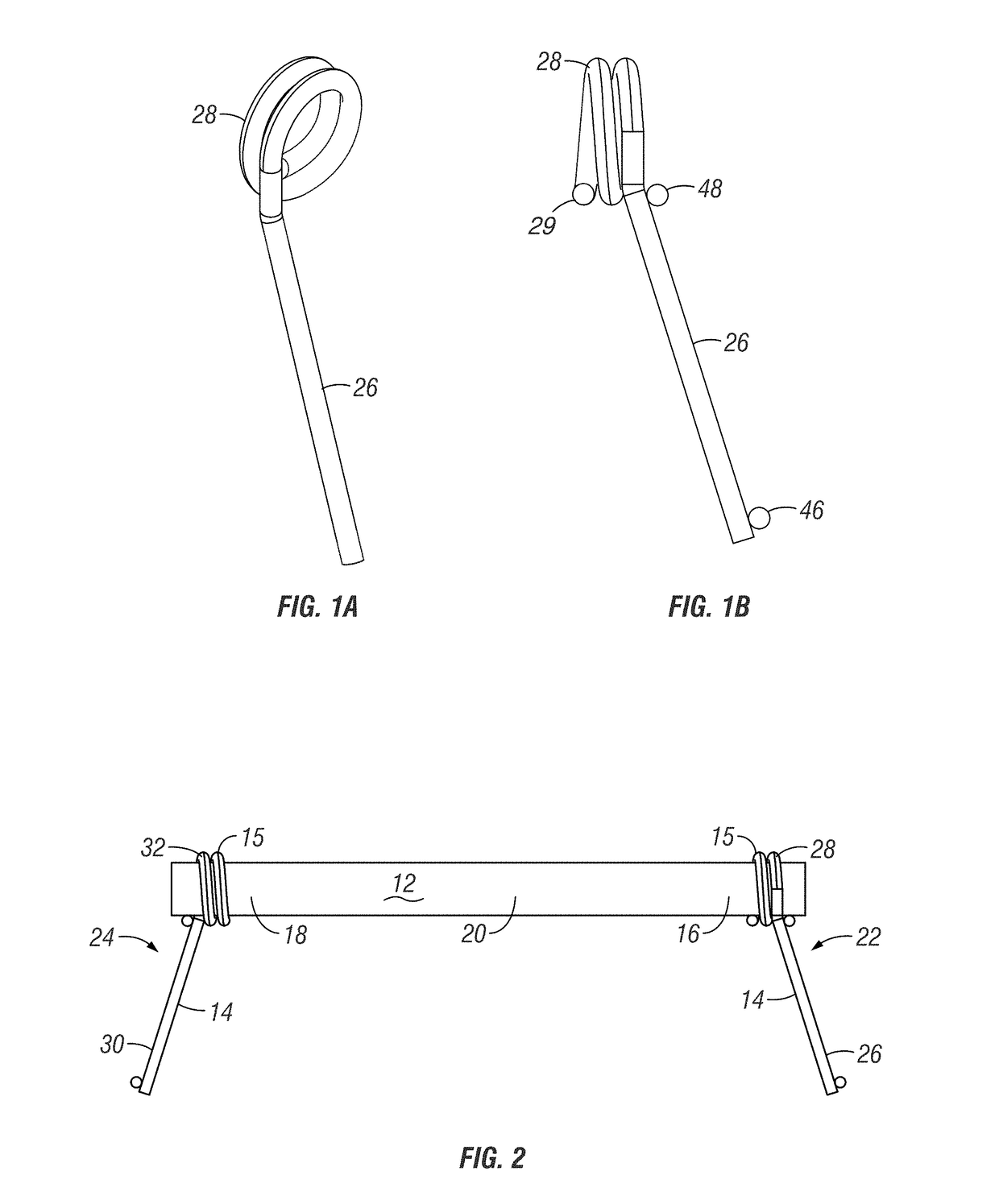

[0031]FIG. 1 illustrates a perspective view of an example embodiment of a road basket 10. The road basket 10 may include a plurality of dowels 12, preferably composed of a non-metallic material. However, the dowels 12 may be made from any desired non-corrosive material that provide the appropriate structural properties. For example, the dowels 12 may be composed from fiberglass, a glass fiber reinforced polymer, or a fiber reinforced plastic (FR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com