Allopurinol dual-release preparation and preparation method thereof

A dual-release, allopurinol technology, applied in pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problem of short action time, inability to maintain stable and effective anti-gout blood drug concentration, and easy occurrence of adverse reactions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

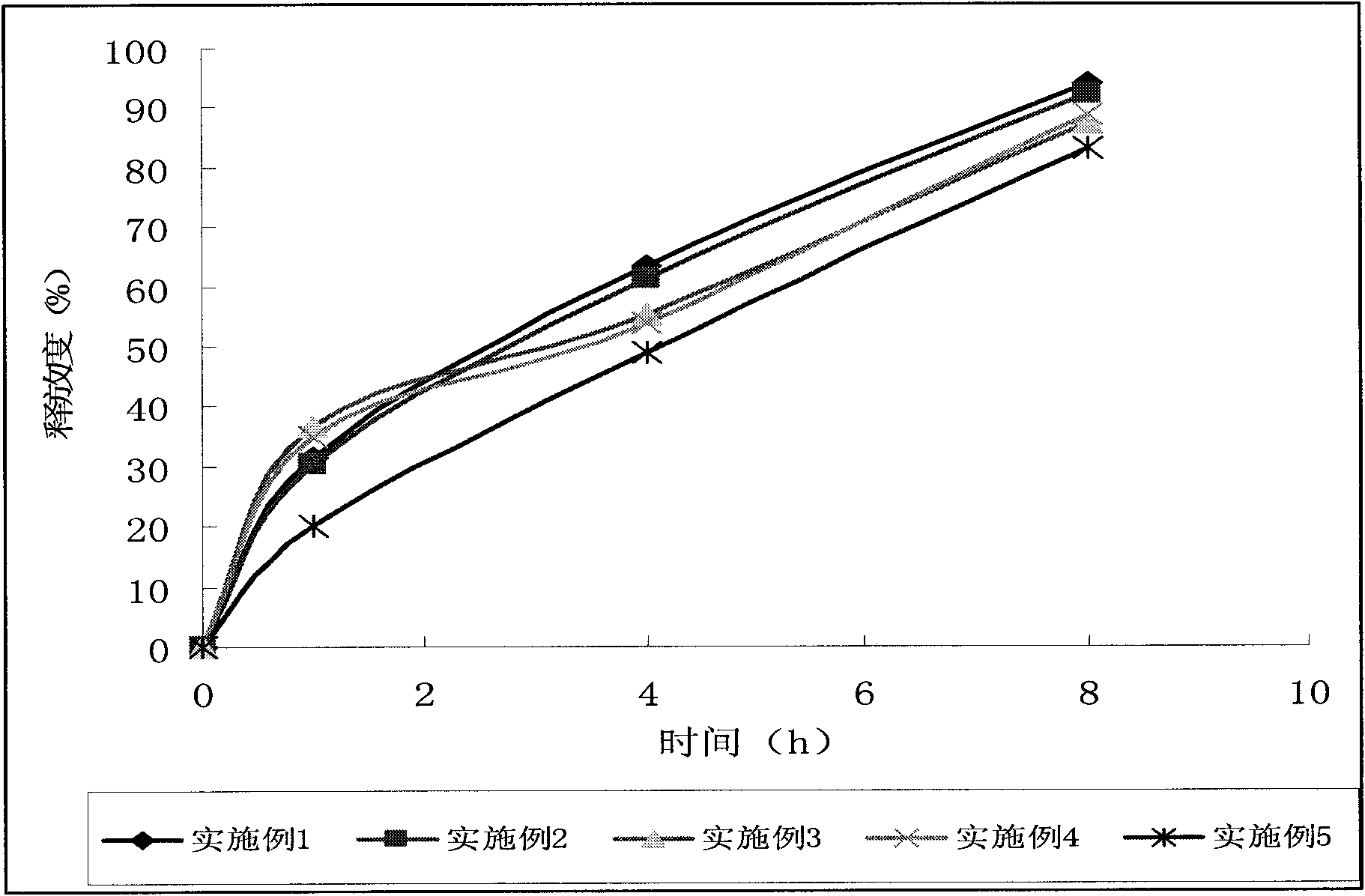

Image

Examples

Embodiment 1

[0026] quick release part

[0027] Allopurinol 50g

[0028] Microcrystalline Cellulose 101 20g

[0029] Starch 30g

[0030] Povidone K30 3g

[0031] Magnesium stearate 0.5g

[0032] Sustained release part

[0033] Allopurinol 200g

[0034] Hypromellose K100LV 40g

[0035] Microcrystalline Cellulose 101 50g

[0036] Povidone K30 15g

[0037] Magnesium stearate 0.8g

[0038]

[0039] Made into 1000 pieces / grain

[0040] Preparation:

[0041] (1) Preparation of immediate-release granules: crush allopurinol through an 80-mesh sieve, and set aside; weigh allopurinol, starch, povidone K30, and microcrystalline cellulose 101 of the prescribed amount, mix well, add appropriate amount of water, and carry out Wet granulation, wet granulation with a 16-mesh sieve, drying at 50°C, granulation with a 20-mesh sieve, calculate the yield, add magnesium stearate, mix, and set aside.

[0042] (2) Preparation of sustained-release granules: cr...

Embodiment 2

[0046] Quick release part:

[0047] Allopurinol 50g

[0048] Microcrystalline Cellulose 101 25g

[0049] Starch 26g

[0050] Povidone K30 3.7g

[0051] Magnesium stearate 0.5g

[0052] Sustained release part

[0053] Allopurinol 200g

[0054] Hypromellose K4M 25g

[0055] Hypromellose E5 26g

[0056] Microcrystalline Cellulose 101 45g

[0057] Povidone K30 15g

[0058] Magnesium stearate 0.8g

[0059]

[0060] Made into 1000 pieces / grain

[0061] Preparation method: with embodiment 1.

Embodiment 3

[0063] Quick release part:

[0064] Allopurinol 125g

[0065] Microcrystalline Cellulose 101 38g

[0066] Sodium carboxymethyl starch 23g

[0067] Povidone K 30 12g

[0068] Magnesium Stearate 1g

[0069] Sustained release part:

[0070] Allopurinol 125g

[0071] Hypromellose K100LV 55g

[0072] Microcrystalline Cellulose 101 40g

[0073] Povidone K 30 15g

[0074] Magnesium Stearate 1g

[0075]

[0076] A total of 1000 pieces / grain

[0077] Preparation method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com