Optical image capturing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment (embodiment 1)

The First Embodiment (Embodiment 1)

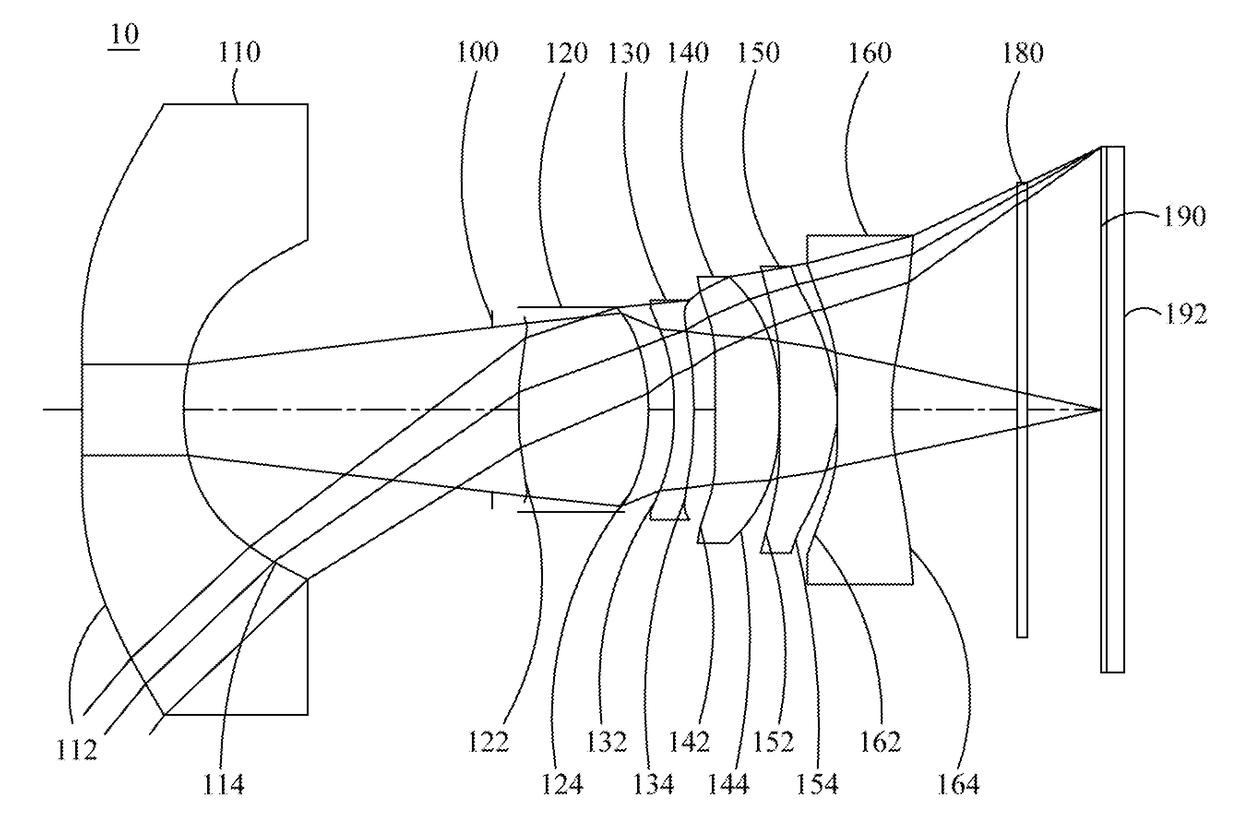

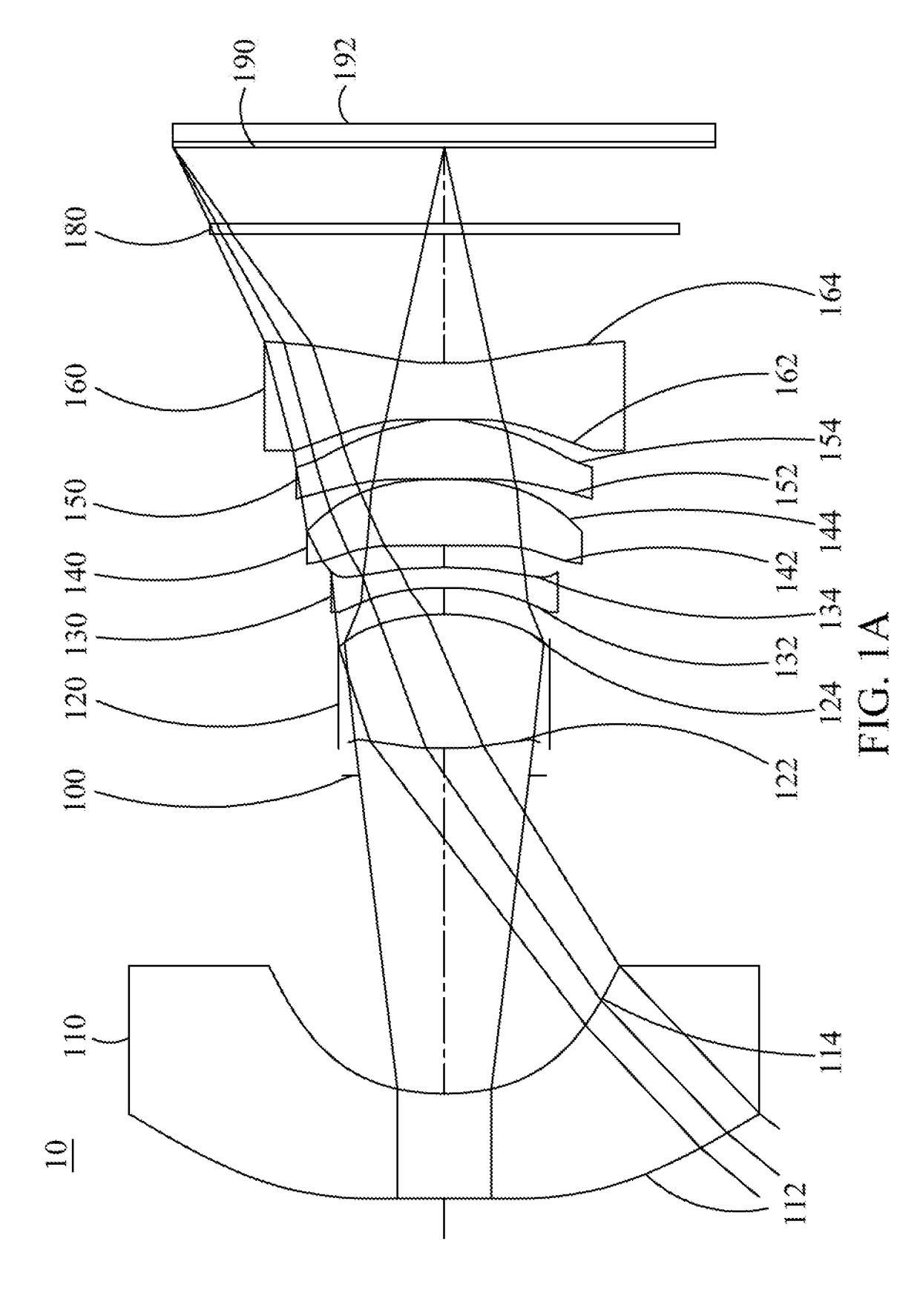

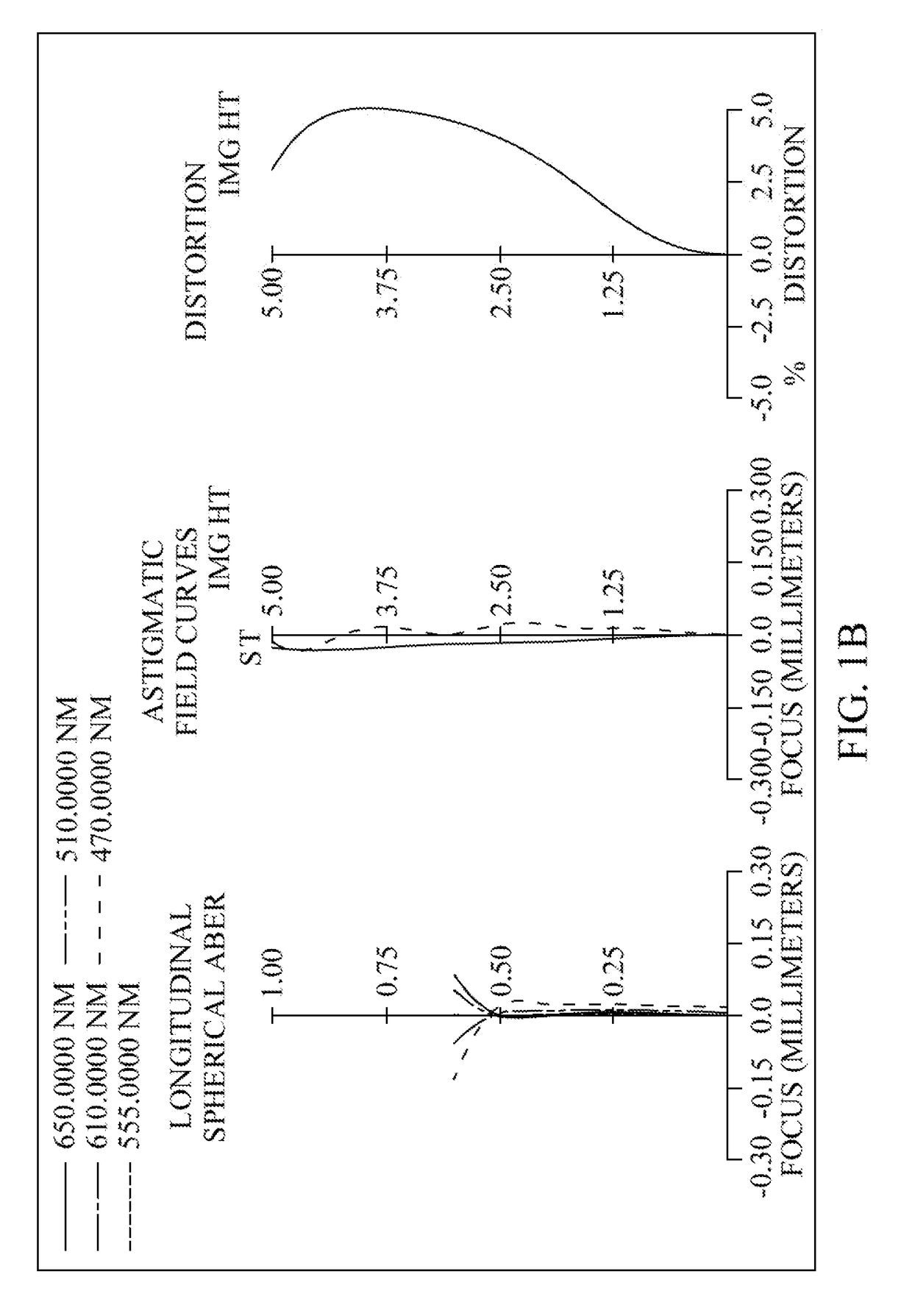

[0105]Please refer to FIG. 1A and FIG. 1B. FIG. 1A is a schematic view of the optical image capturing system according to the first embodiment of the present application, FIG. 1B is longitudinal spherical aberration curves, astigmatic field curves, and an optical distortion curve of the optical image capturing system in the order from left to right according to the first embodiment of the present application, and FIG. 1C is a lateral aberration diagram of tangential fan, sagittal fan, the longest operation wavelength and the shortest operation wavelength passing through an edge of the entrance pupil and incident on the image plane by 0.7 HOI according to the first embodiment of the present application. As shown in FIG. 1A, in order from an object side to an image side, the optical image capturing system includes a first lens element 110, an aperture stop 100, a second lens element 120, a third lens element 130, a fourth lens element 140, a fifth le...

second embodiment (embodiment 2)

The Second Embodiment (Embodiment 2)

[0167]Please refer to FIG. 2A, FIG. 2B and FIG. 2C, FIG. 2A is a schematic view of the optical image capturing system according to the second embodiment of the present application, FIG. 2B is longitudinal spherical aberration curves, astigmatic field curves, and an optical distortion curve of the optical image capturing system in the order from left to right according to the second embodiment of the present application, and FIG. 2C is a lateral aberration diagram of tangential fan, sagittal fan, the longest operation wavelength and the shortest operation wavelength passing through an edge of the entrance pupil and incident on the image plane by 0.7 HOI according to the second embodiment of the present application. As shown in FIG. 2A, in order from an object side to an image side, the optical image capturing system includes an aperture stop 200, a first lens element 210, a second lens element 220, a third lens element 230, a fourth lens element 24...

second embodiment

The detailed data of the optical image capturing system of the second embodiment is as shown in Table 3.

TABLE 3Data of the optical image capturing systemf = 5.707 mm; f / HEP = 1.6; HAF = 52.5 degFocalSurface #Curvature RadiusThicknessMaterialIndexAbbe #length0Object1E+181E+181Ape. stop1E+18−0.0362Lens 16.0362135740.518Plastic1.54555.9619.801313.243048450.00041E+180.2325Lens 2−62.642793640.844Plastic1.54555.967.6246−3.9238325970.1027Lens 370.090734140.375Plastic1.64222.46−9.62785.7134072080.4259Lens 45.4102976550.560Plastic1.54555.964185.470105.2247263740.66511Lens 5−4.8015794021.600Plastic1.54555.965.63712−2.0970318560.10013Lens 63.3053170371.267Plastic1.64222.46−10.827141.9080239091.12515IR-bandstop1E+180.500BK_71.51764.13filter161E+181.12017Image plane1E+180.000Reference wavelength (d-line) = 555 nm; shield position: The clear aperture of the fourth surface is 1.775 mm. The clear aperture of the fourteenth surface is 5.700 mm.

As for the parameters of the aspheric surfaces of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com