An adhesive device for attaching a false eyelash and a false eyelash kit

a technology for false eyelashes and adhesive devices, which is applied in the field of adhesive devices for false eyelashes and false eyelash kits, can solve the problems of difficult manufacturing of film and polyester film cut into thin strips, difficulty in attaching false eyelashes by users by using such adhesive in such containers, and difficulty in disposable false eyelashes to be used on daily basis. , to achieve the effect of reducing irritation by foreign matter, thicker thickness and natural eyelashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

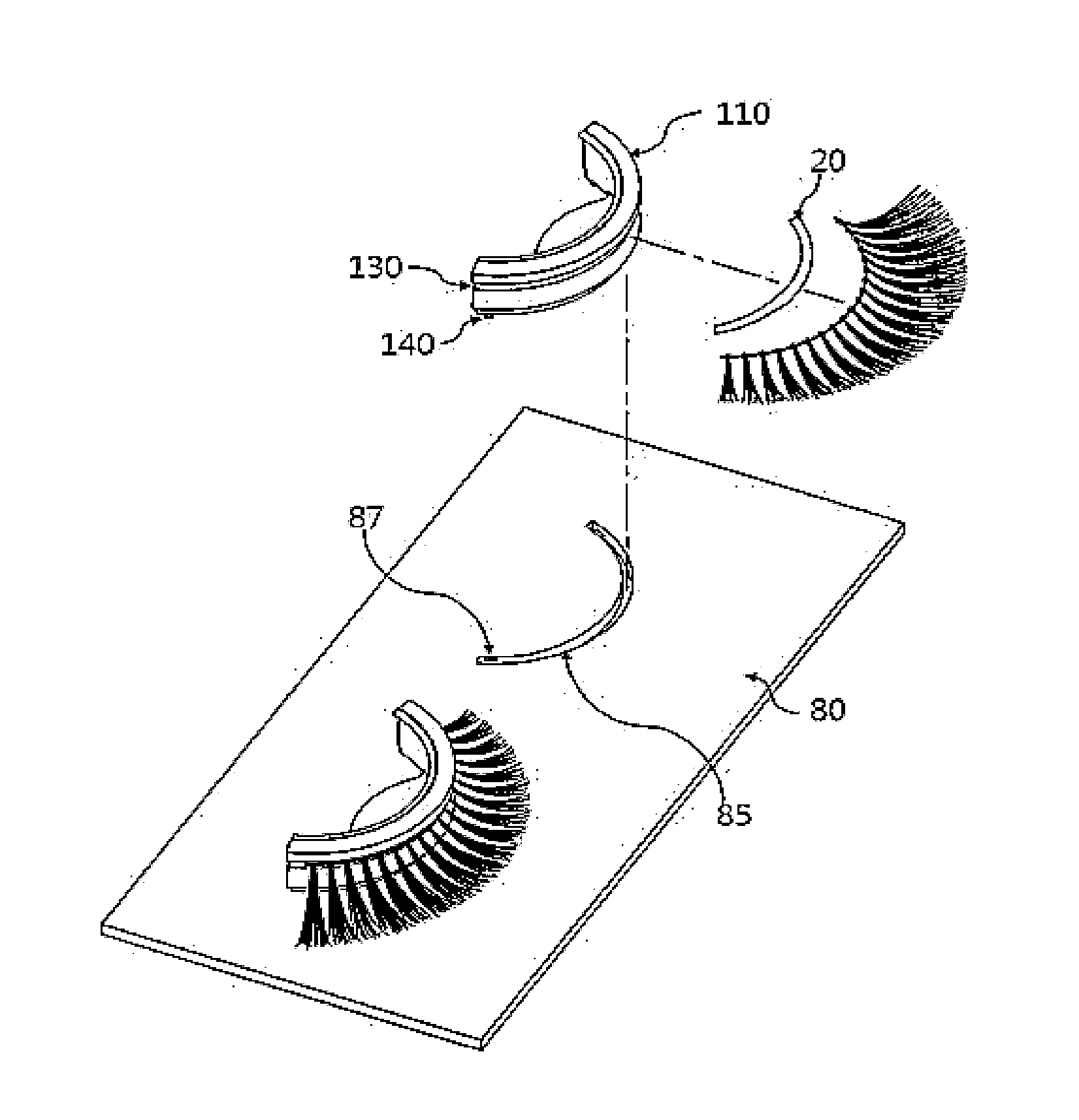

[0064]The adhesive device for false eyelashes and false eyelash kit of this invention will be explained in detail below by making reference to the attached figures.

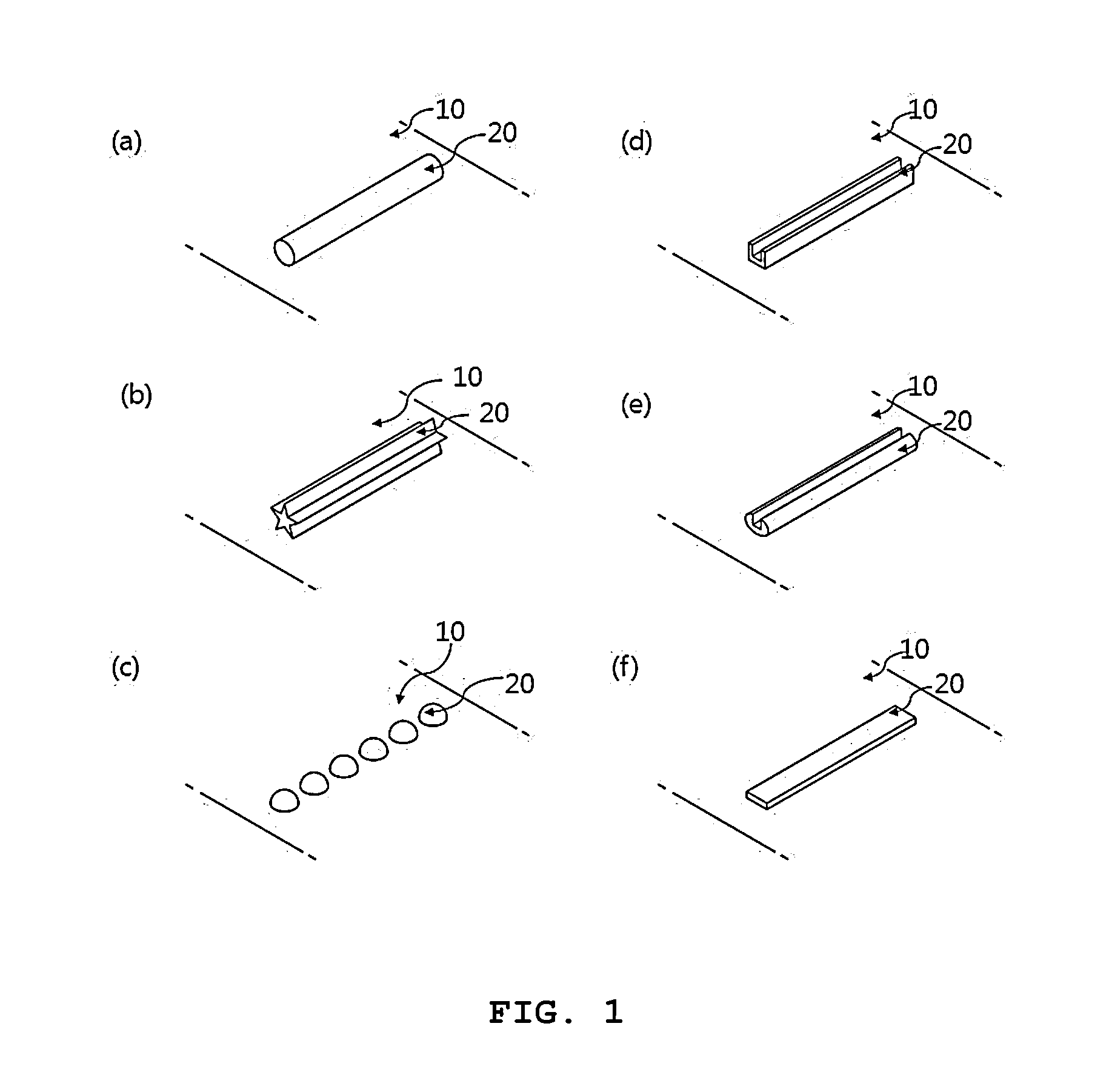

[0065]The adhesive device for false eyelashes of this invention is made by solidifying the prescribed adhesive in prescribed configuration and thickness. First, the manufacturing procedure of the adhesive device for false eyelashes is explained below.

[0066]There are 5 methods of manufacturing the adhesive device for false eyelashes.

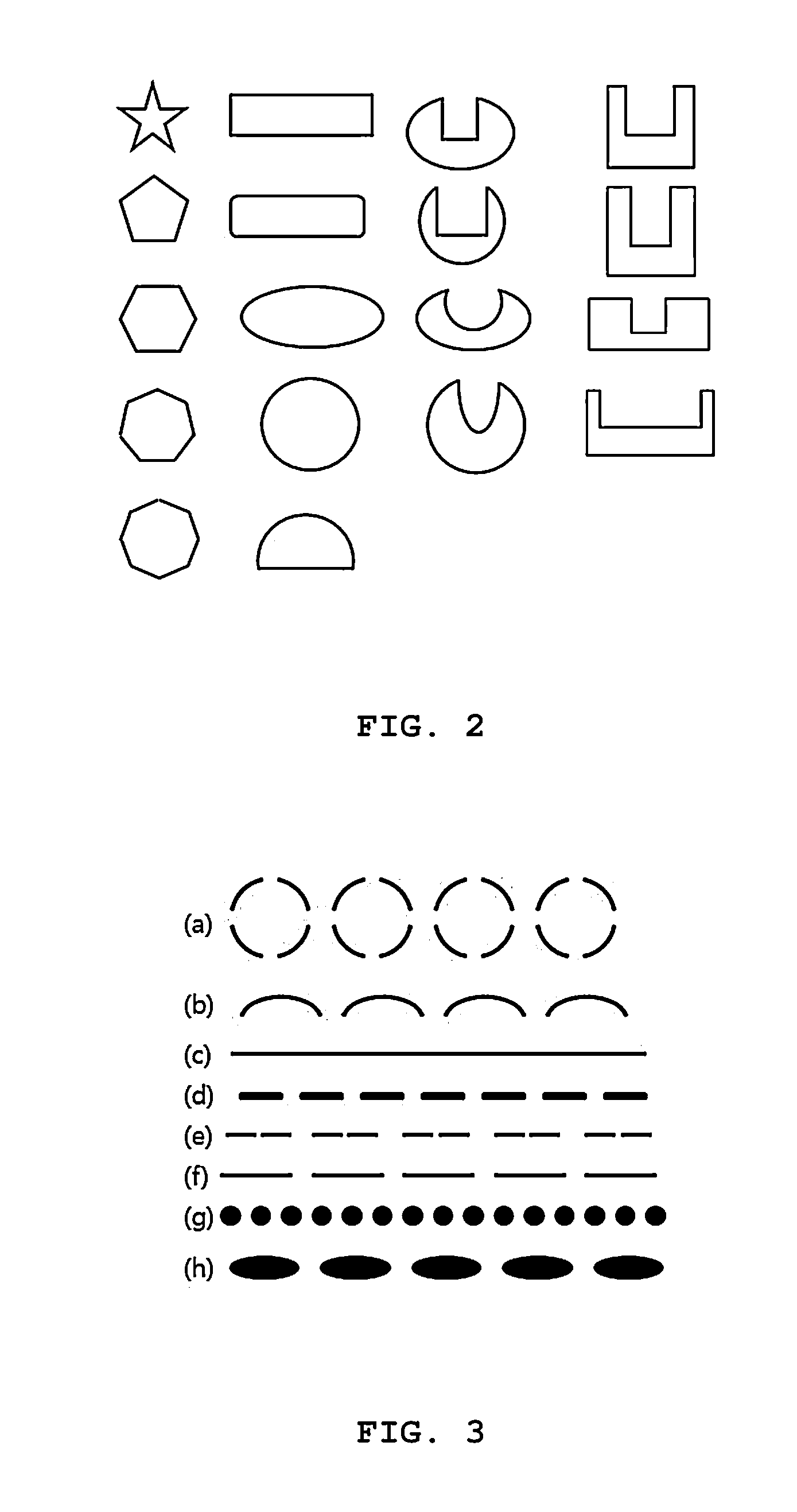

[0067]The first method is to drop the adhesive onto the release paper (the release paper means one of release paper, release film and release plastic in this invention) through the nozzle of the dispenser for liquid phase adhesive in prescribed configuration and thickness in accordance with the configuration of the tip of the said nozzle. It is then left to be naturally dried at room temperature.

[0068]Depending on the circumstances, adhesive is coated again by dropping it on to the naturally dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com