Fabric pretreatment for digital printing

a technology of substrate pretreatment and digital printing, applied in the direction of dyeing process, printing, textiles and paper, etc., can solve the problems of over-penetration or under-penetration of the textile, interfere with the permanent adhesion of the digital ink, etc., to maintain the appearance and color, improve the image durability, and improve the effect of color intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0051]In these examples, the following reagents were used

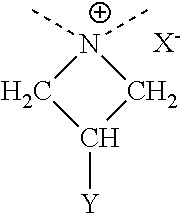

Polycup™ 172 is a polyamide-epichlorohydrin azetidinium functionalized polymer available from Ashland-Hercules Water Technologies.

Polycup™ 7360 is a polyamine-epichlorohydrin azetidinium functionalized polymer available from Ashland-Hercules Water Technologies.

Danfix™ 303 is a copolymer of a quaternary ammonium salt of N,N-dimethyldiallylammonium chloride and sulfur dioxide of about 4000 or 5000 g / mole molecular weight available from Nittobo

BYK®-347—surfactant available from Byk Chemie in Europe

DPG is dipropylene glycol

Acticide™ MV is 10.6 wt. % 5-chloro-2-methyl-4-isothizolin-3-one and 3.5 wt. % 2-methyl-4-isothiazolin-3-one available from Thor GmbH in Trumbell, Conn., USA.

Examples for Cationic Polyurethanes

example a

Pretreatment

[0052]

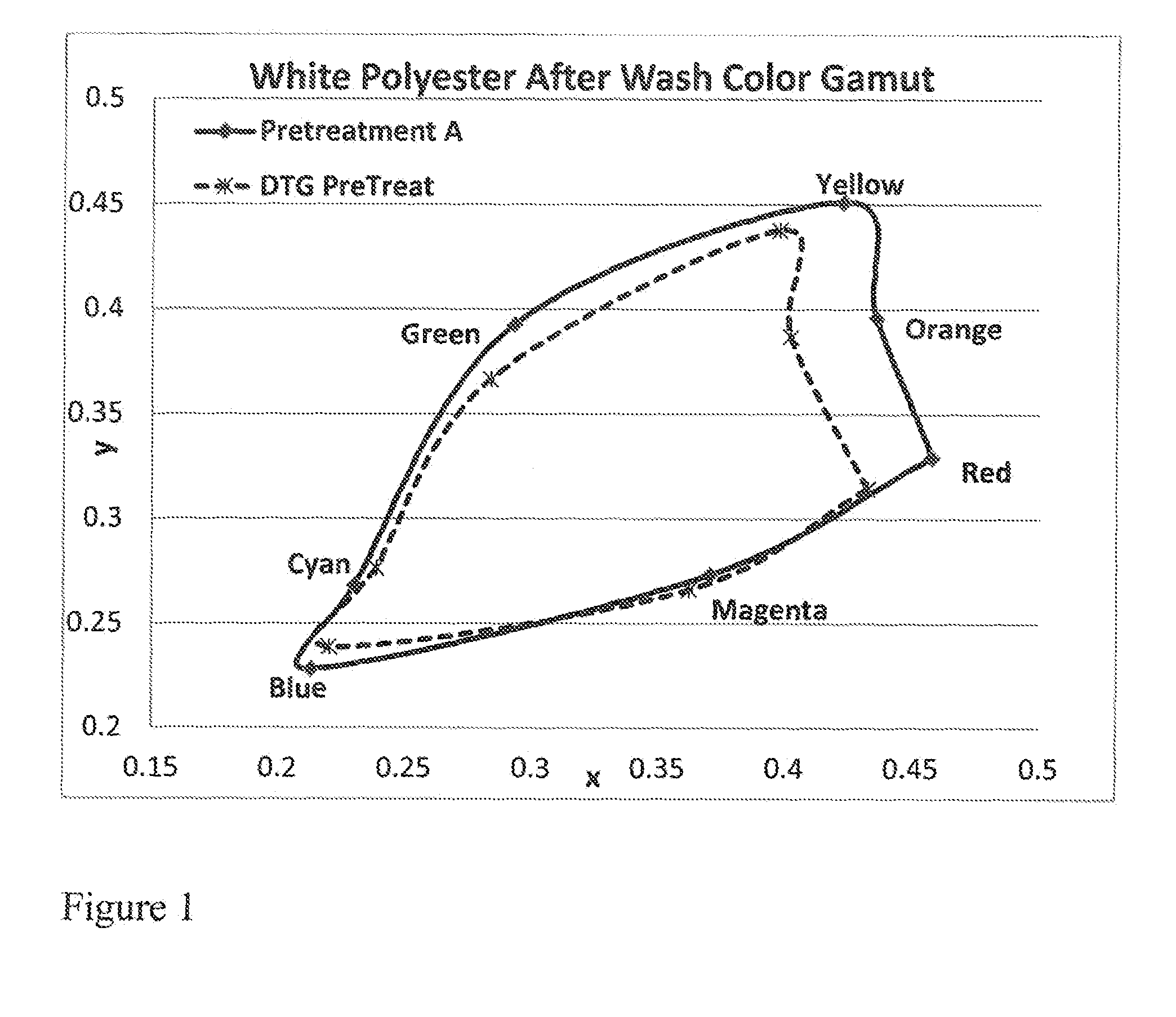

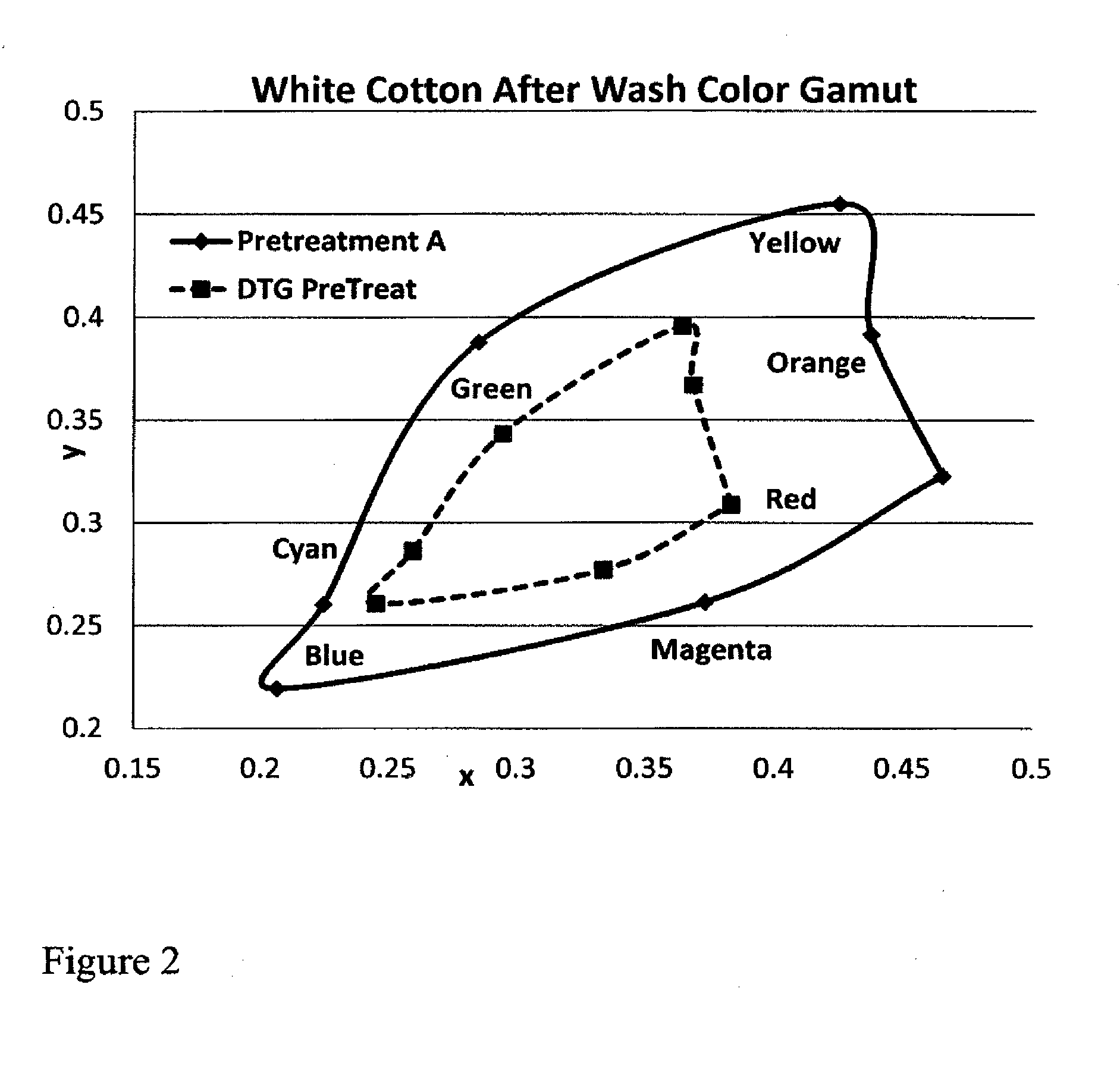

TABLE 1Pretreatment CompositionsIngredientPretreatment APretreatment BPolycup ™1.55 parts1.557360 or 172by weightDanfix ® 3031.551.55Itaconic acid0.001.55Dipropylene0.080.08glycolIsopropyl0.810.81alcoholByk ™ 3470.010.01Acticide MV0.00040.0004WaterresidualresidualAll parts by weight are based on the active ingredient and exclude water that may have been in the commercial product.

Recipes for Pretreatment Compositions Using Cationic Polymer and Azetidiniumpolyurethanes and Control Pretreatments

Procedure for Making Pre-Treatments

Padding Method for Applying Pretreatment

[0053]The pretreatment was applied to fabric pieces for most of the examples with a spray application, a padding method is also commonly used in the textile industry. The pretreatment solution was allowed to soak into the fabric for about 3 minutes or until the fabric was completely saturated. The fabric was then passed through a nip (at 30-40 psi) formed by a rubber covered bottom roll and a steel top r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com