Low density edible animal chews and methods of making same

a low-density, chewing technology, applied in the field of low-density edible chews, can solve the problems of reducing the production efficiency of chewing toys, so as to achieve low density and low density , the effect of smooth exterior surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0082]Ingredients for a 500 Kg batch of Dry Mix were weighed out according to the percentages shown in Table 1 into a batch mixer and blended for five minutes. Although pre-gelled corn flour was used, additionally or alternatively any pre-gelled cereal flour can be used.

[0083]The Dry Mix was metered into an Evolum EV53 (Clextral) twin screw extruder along with the glycerin / phosphoric acid mixture and water in the proportions shown in Table 1 and equaling 115 Kg / hour, where they were mixed under pressure (64 bars) and achieved a temperature of 117° C. to form a plastic dough. Phosphoric acid is not required but was included for additional preservative effect.

TABLE 1AmountIngredients(%)DRY MIXPregelled Corn Flour83.58Wheat Flour6.0Brewer's Dried Yeast3.0Calcium Hydrogen Phosphate3.0Distilled Monoglyceride1.5Vitamin Premix1.5Potassium Sorbate0.6Titanium Dioxide0.4Calcium Propionate0.4BHT Powder0.02TOTAL100EXTRUSIONDry Mix73.9Glycerin / Phosphoric Acid (16:1)16.3Water9.8TOTAL100

[0084]The ...

example 2

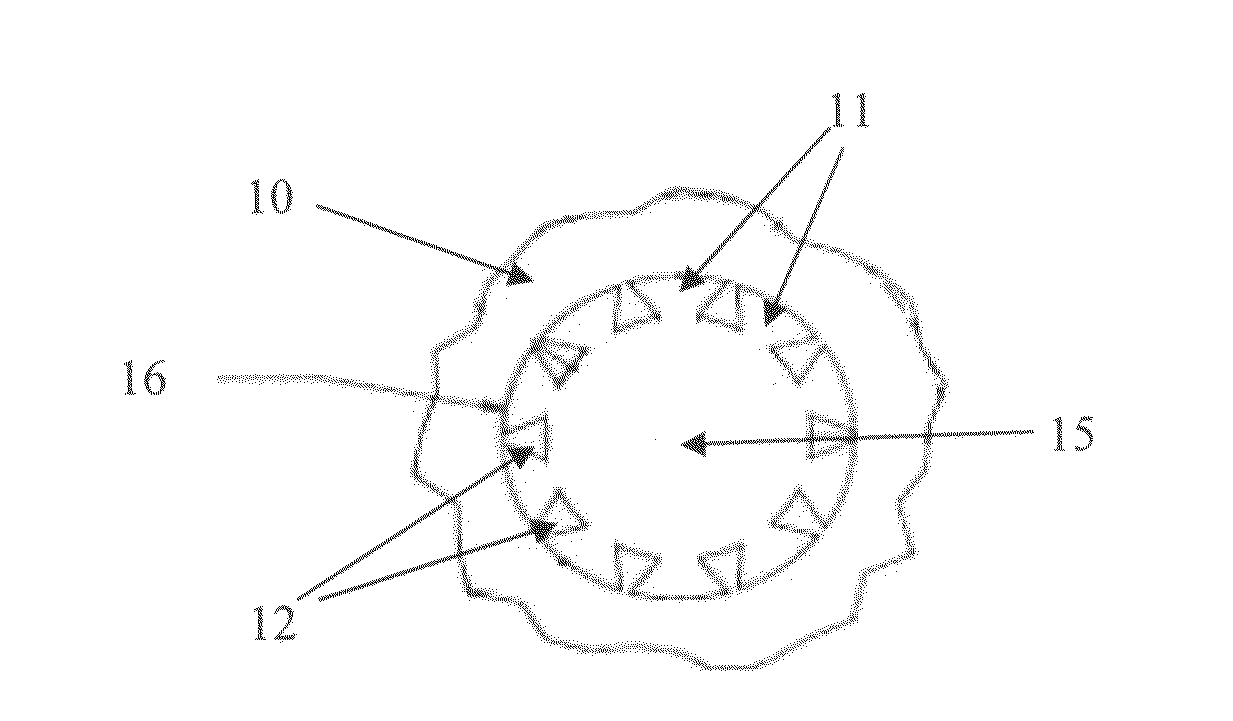

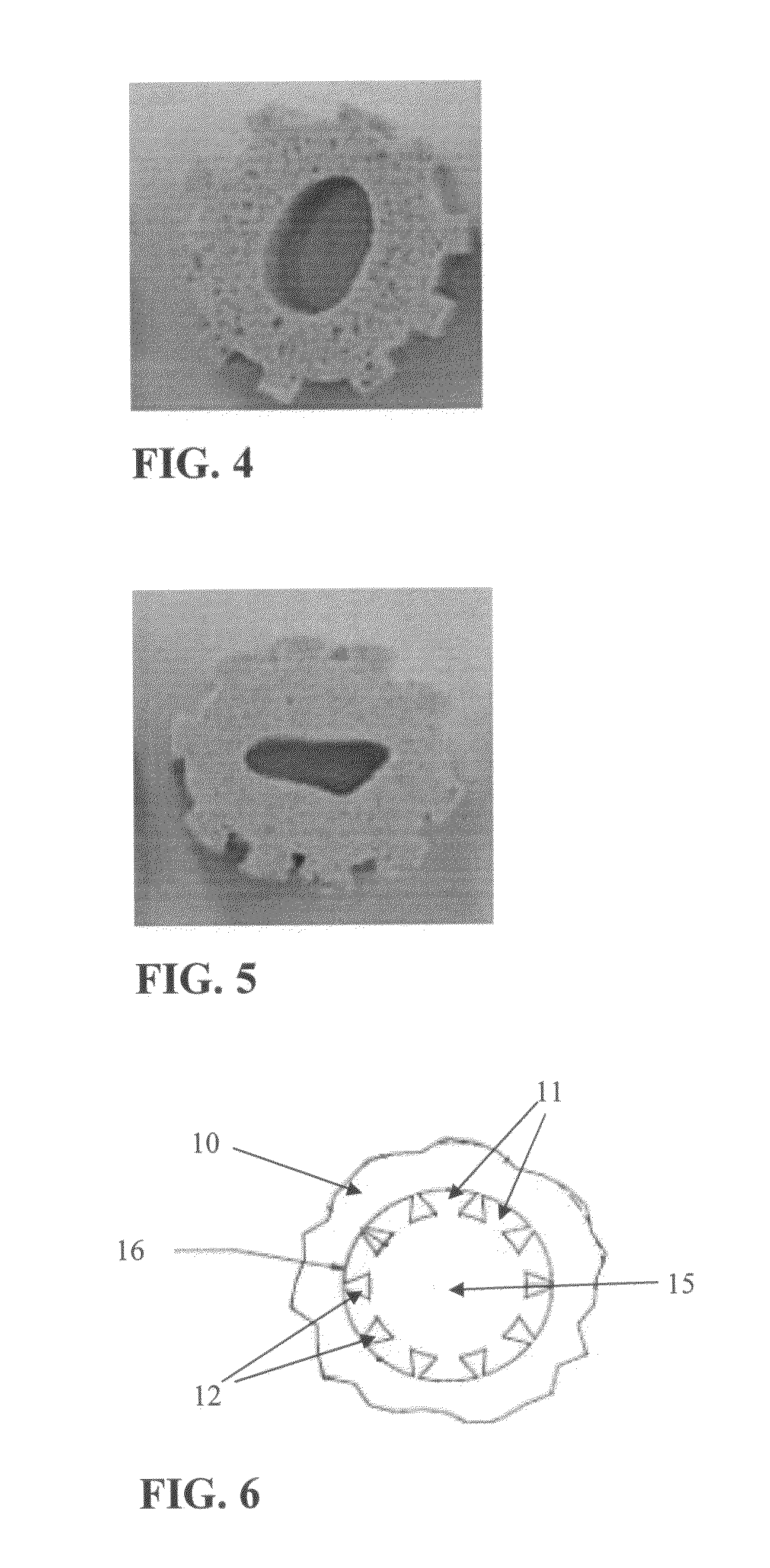

[0086]Example 1 was repeated with the following exceptions. 0.5% sodium bicarbonate was added to the dry mix shown in Table 1 and the pre-gelled corn flour was reduced accordingly to 83.08%. The maximum pressure and SME were 67 bars and 447 KJ / Kg respectively. The plastic dough was then extruded through a die system with opening shown in FIG. 6 and cut into 120 mm long pieces having a density of 0.74 Kg / L and with an expanded cellular internal structure (FIG. 2). The die with dovetail design (FIG. 6) was found to avoid a blistered, rough outer surface and produce an acceptably smooth outer surface. Moreover, a single tubular insert was inserted within the die opening to form a hollow part in the product piece (FIG. 2).

example 3

[0087]Example 2 was repeated with the following exceptions. 1% sodium bicarbonate was added to the dry mix shown in Table 1 and the pre-gelled corn flour was reduced accordingly to 82.58%. The maximum pressure and SME were 67 bars and 452 KJ / Kg respectively. The plastic dough was then extruded through a die system with opening shown in FIG. 6 and cut into 120 mm long pieces having a density of 0.68 Kg / L and with an expanded cellular internal structure (FIG. 3). The die with dovetail design (FIG. 6) was found to avoid a blistered, rough outer surface and produce an acceptably smooth outer surface. Moreover, a single tubular insert was inserted within the die opening to form a hollow part in the product piece (FIG. 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com