Filter medium for liquid filter and method for manufacturing same

a technology of liquid filter and filter medium, which is applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of difficult to make fine pores not more than 1 m, difficult to create uniform pores, and difficult to make pores less than 1 m, etc., to achieve excellent air permeability and excellent water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

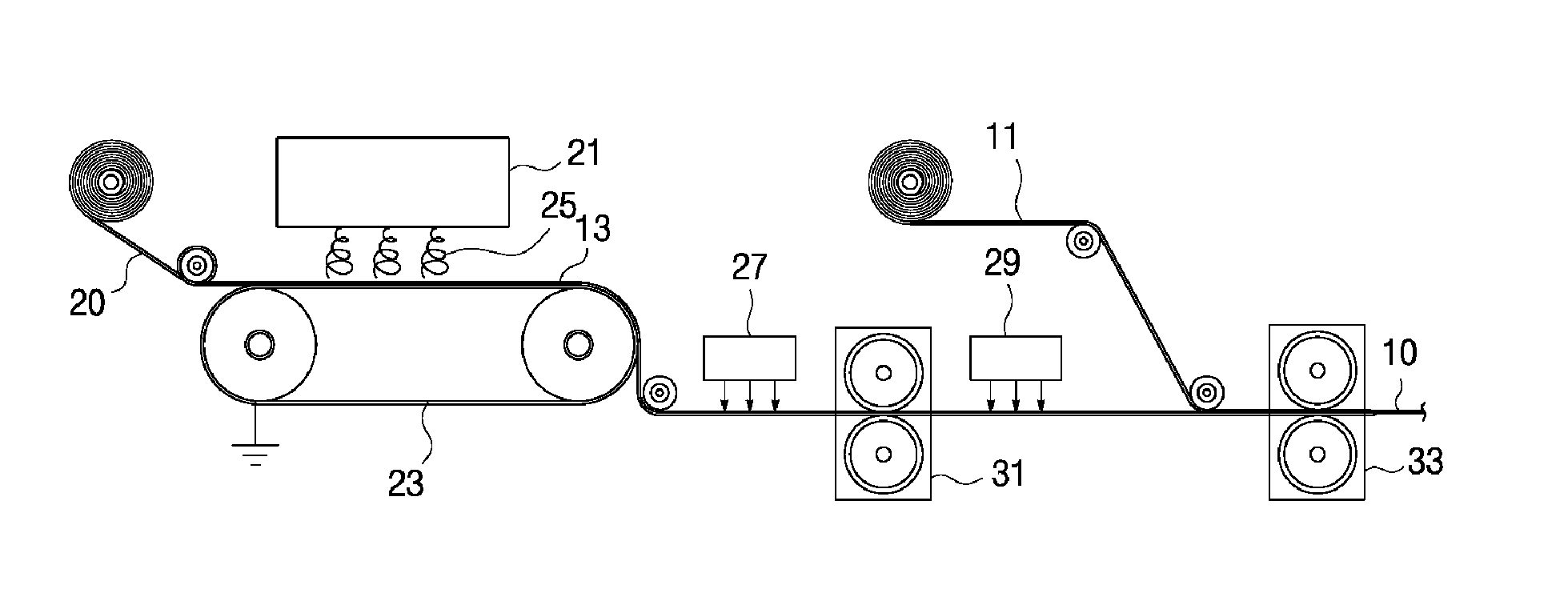

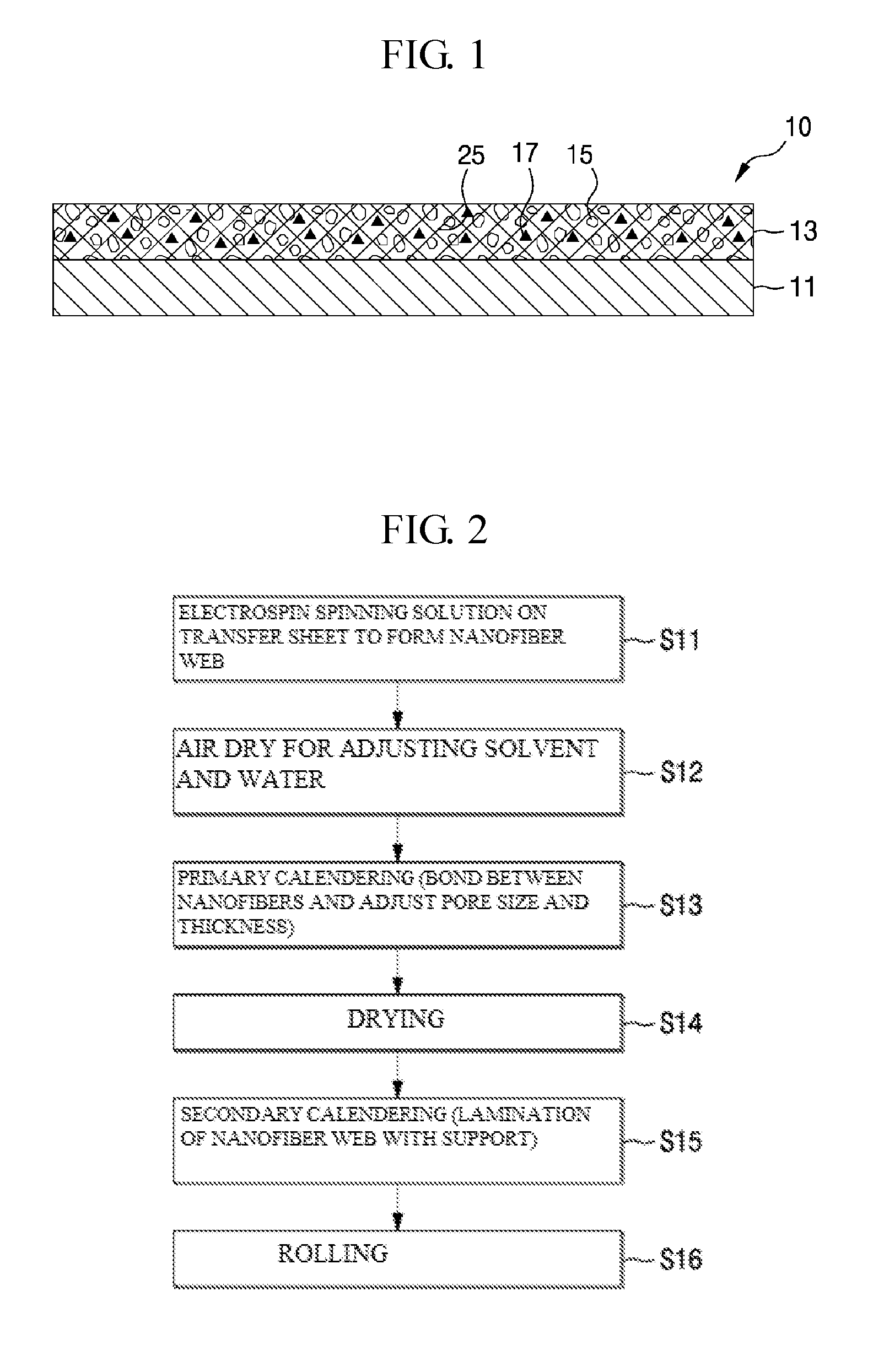

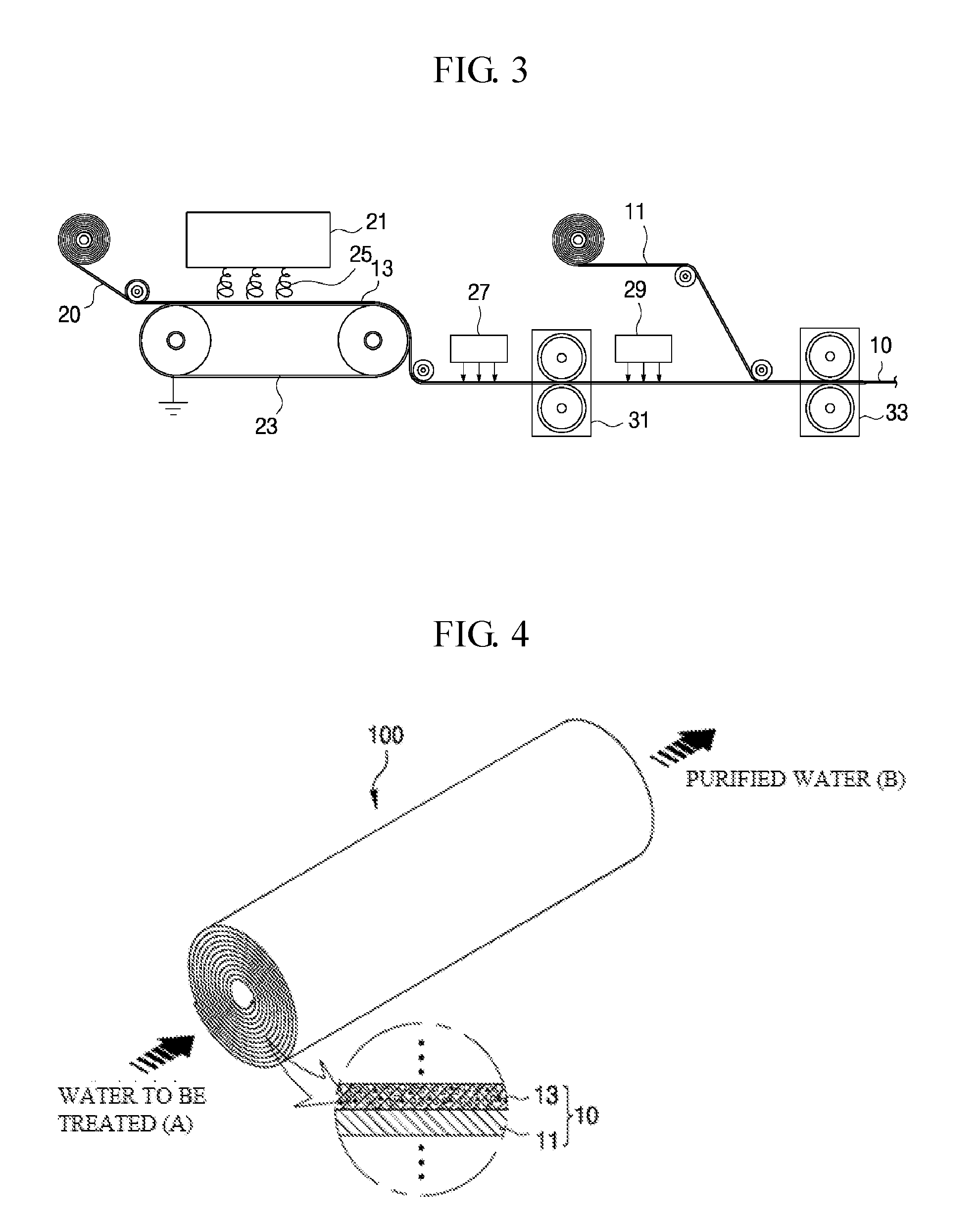

[0141]In Example 1, PVdF (Polyvinylidene fluoride) as a polymer material was dissolved in a solvent (DMAc:Acetone=7:3) to become 14 wt % to thus prepare a spinning solution. The spinning solution was moved to a mixing tank of an electrospinning apparatus to set a voltage applied to the electrospinning apparatus to 100 kV, a distance from a spinning nozzle and a collector to 20 cm, a discharge amount per minute to 20 μl / hole, and was electrospun under a spinning atmosphere of 30° C. and a relative humidity of 60%, to have prepared a nanofiber web of a weight of 3 gsm with a pore size of 1 μm.

[0142]The thus-obtained nanofiber web was calendered under the condition of 150° C. and 1 Kgf / cm2 thereby have formed a bond between the nanofibers and thus have implemented a fixed pore structure, and the calendered nanofiber web was laminated with a nonwoven fabric under the condition of 130° C. and 1 Kgf / cm2 to have produced a filter medium. The nonwoven fabric used in this Example 1 was a non...

example 2

[0151]In Example 2, PVdF (Polyvinylidene fluoride) as a polymer material was dissolved in a solvent (DMAc:Acetone=7:3) to become 10 wt % to thus prepare a spinning solution. The spinning solution was moved to a mixing tank of an electrospinning apparatus to set a voltage applied to the electrospinning apparatus to 100 kV, a distance from a spinning nozzle and a collector to 20 cm, a discharge amount per minute to 20 μl / hole, and was electrospun under a spinning atmosphere of 30° C. and a relative humidity of 60%, to have prepared a nanofiber web of a weight of 3 gsm with a pore size of 0.45 μm.

[0152]The thus-obtained nanofiber web was calendered under the condition of 150° C. and 1 Kgf / cm2 thereby have formed a bond between the nanofibers and thus have implemented a fixed pore structure, and the calendered nanofiber web was laminated with a nonwoven fabric under the condition of 130° C. and 1 Kgf / cm2 to have produced a filter medium. The nonwoven fabric used in this Example 2 was th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com