Carbon member, carbon member manufacturing method, redox flow battery and fuel cell

a technology of carbon member and manufacturing method, which is applied in the direction of cell components, sustainable manufacturing/processing, indirect fuel cells, etc., can solve the problems of battery member prone to delamination, difficult to achieve satisfactory conduction at the battery material interface, and unsatisfactory welding properties of adhesives, etc., to achieve excellent conductivity, superior flexural strength, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 29

, Reference Examples 1 and 2, Comparative Examples 1 to 10

[0148]Using resin compositions P01 to P15 shown in Table 1, carbonaceous materials C1 to C7 shown in Table 2, and porous carbon materials EL1 to EL8 shown in Table 3, the methods described below were used to manufacture and evaluate carbon members of Example 1 to Example 29, Reference Examples 1 and 2, and Comparative Example 1 to Comparative Example 10 shown in Table 4 to Table 10.

TABLE 1P01P02P03P04P05P06P07P08P09P10P11VS200A (homo PP) MFR = 0.5 (230° C.), 2.16 kgmass %95PMB60A (block PP) MFR = 63 (230° C.), 2.16 kgmass %95PL400A (homo PP) MFR = 2 (230° C.), 2.16 kgmass %95100PM801A (homo PP) MFR = 13 (230° C.), 2.16 kgmass %95PP2228 (PP-based copolymer) MFR = 30 (230° C.), 2.16 kgmass %100Q100F (PP-based copolymer) MFR = 0.6 (230° C.), 2.16 kgmass %90PM940M (random PP) MFR = 30 (230° C.), 2.16 kgmass %1007040PB0800M (polybutene-1) MFR = 820 (230° C.), 2.16 kgmass %100DP8510M (polybutene-1) MFR = 168 (230° C.), 2.16 kgmass ...

example 1

[0201]Using a unidirectional twin-screw extruder (KTX-30, manufactured by Kobe Steel, Ltd.), 100 parts by mass of the resin composition P01 and 600 parts by mass of the carbonaceous material C1 were compounded under an open-head state including a temperature setting of 210° C. and a rotational rate of 400 rpm, thus forming a mixture. Subsequently, the mixture was extrusion-molded at a temperature setting of 200° C. using a single screw sheet extruder, thereby forming a sheet-like first layer having a length of 200 mm, a width of 200 mm and a thickness of 1.5 mm (first molding step).

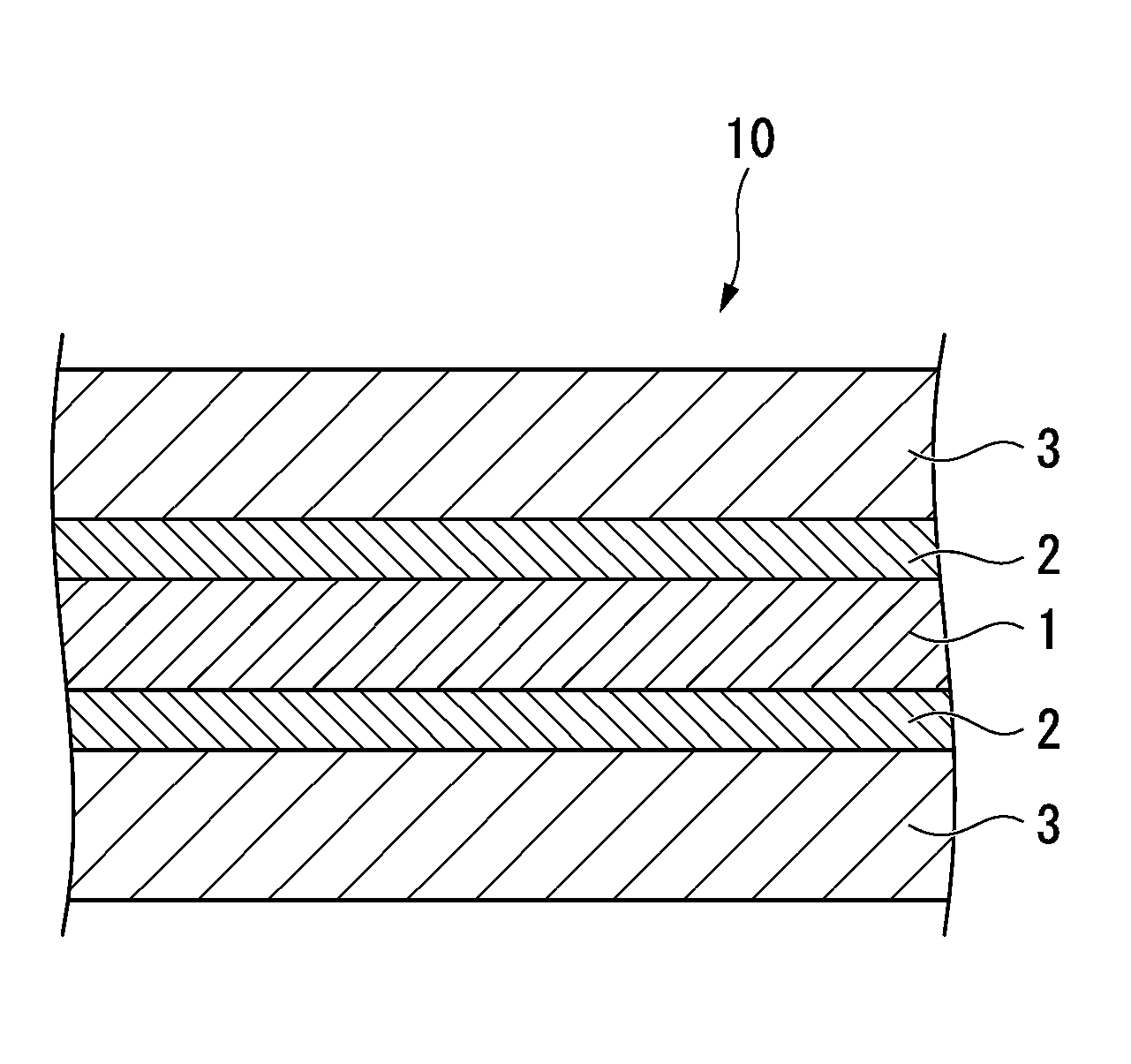

[0202]Further, 100 parts by mass of the resin composition P08, 300 parts by mass of the carbonaceous material C1 and 100 parts by mass of the carbonaceous material C4 were compounded to prepare a mixture and then extrusion molded in a similar manner to the first layer, thereby forming a sheet-like second layer having a length of 200 mm, a width of 200 mm and a thickness of 1.5 mm (second molding step). Th...

example 2

[0205]Using the same method as Example 1, a mixture for forming the first layer was produced, and by subsequently shaping and extruding the mixture through the die of a twin screw extruder, a sheet-like first layer having a length of 100 mm, a width of 100 mm and a thickness of 1.5 mm was molded.

[0206]Using the resin composition and the carbonaceous materials shown in Table 4, and in a similar manner to the first layer, a step of forming a mixture for the second layer and a step of molding the mixture into a sheet-like second layer with a length of 100 mm, a width of 100 mm and a thickness of 1.5 mm were performed in a continuous manner. Subsequently, the obtained sheet-like second layer was rolled to prepare a sheet-like second layer with a thickness of 0.1 mm.

[0207]With the exception of using the thus obtained sheet-like first layer and sheet-like second layer, the first layer, second layers and third layers were stacked in the same manner as Example 1 to obtain a carbon member of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com