Polymers prepared using smart templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of a Magnetic Core Silica Shell Nanoparticles (magNP@SiO2)

[0095]Synthesis of magnetic core particles: 6 g FeSO4.7H2O and 7 g anhydrous FeCl3. were dissolved in 200 ml millipore water under N2 with vigorous stirring at 85° C. 15 mL of 25% ammonia (aq) were added quickly into the solution. The solution turned from orange to black due to the precipitation of the magnetite nano-particles. The solution was stirred for 30 min at elevated temperature and then allowed to cool down to RT. Afterwards, the magnetic particles were collected using a magnet and washed with 3×50 mL water and finally with 50 mL 0.2M NaCl solution. The particles were dried at 80° C. under vacuum.

[0096]Synthesis of magnetic core silica shell particles (magNP@SiO2): 2 g of dry magNP were dispersed in 50 mL water by sonication. Then they were collected by a magnet and the supernatant was removed. Then, a 10% (v / v)TEOS-solution (230 mL) was added followed by 200 mL glycerol. The pH was adjusted to 4.6 with g...

example 2

Functionalization of the Magnetic Silica Core-Shell Beads with Glycidoxypropyltrimethoxysilane (GPTMS) to Give magNPepoxy

[0097]3,25 g magNP@SiO2 were dispersed in 50 mL dry toluene under N2-atmosphere by sonication. 1 mL GPTMS was added to the solution and the mixture was heated to reflux under positive nitrogen pressure and stirred using an overhead-stirrer for 30 h. Then, the particles were collected using a magnetic separator and washed with 3 times with 50 mL toluene and 3 time with 50 mL acetone and dried under vacuum at 40° C.

example 3

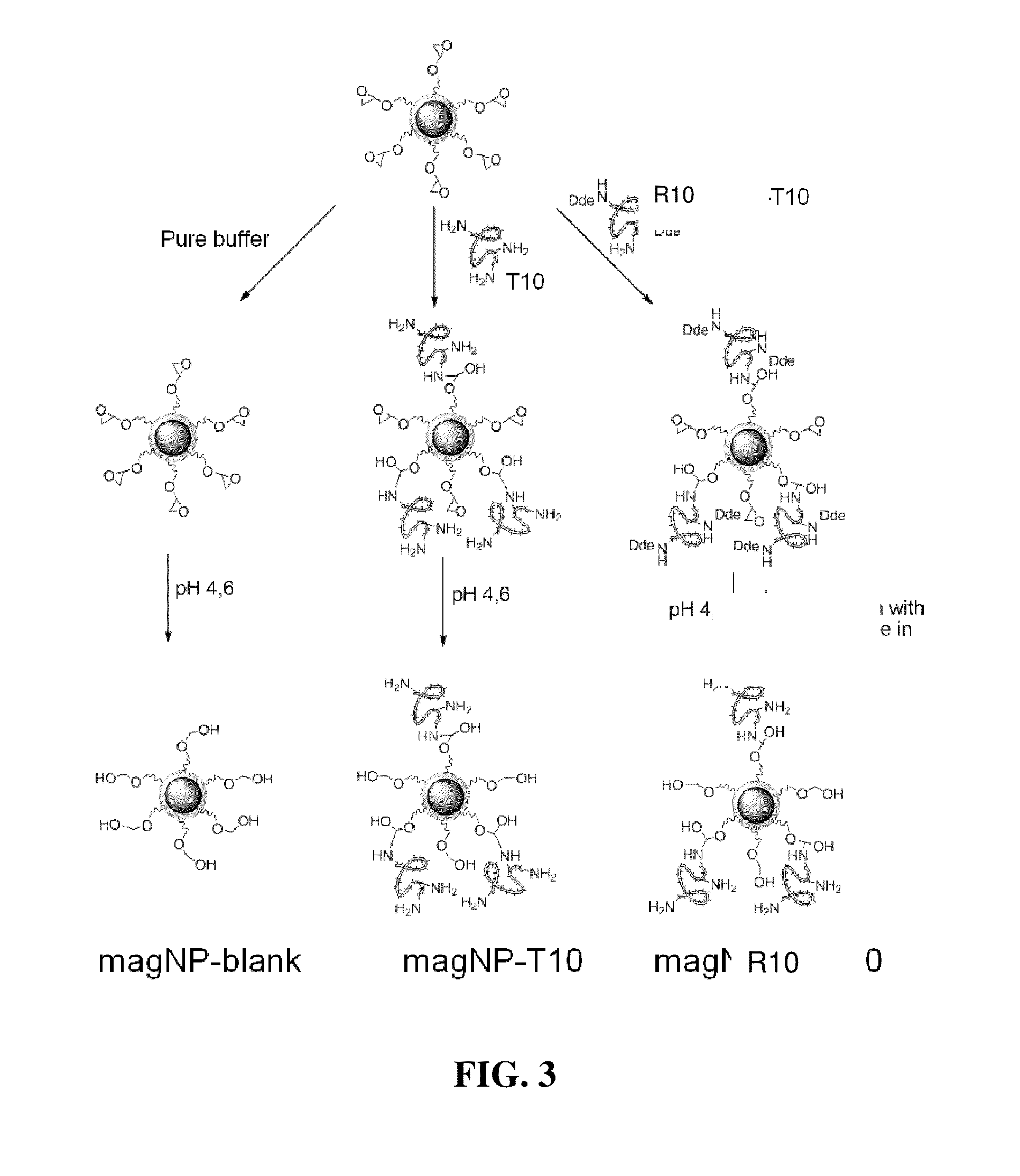

Immobilization of the Decapeptides NH2—O—K—S-L-S-L-S—P-G-K—COOH (T10) and NH2—O-L-S—K—S—K—S—P-G-L-COOH (R10) on the magnetic nanoparticles to give magNP-T10 and magNP-R10 (FIG. 3).

[0098]1 g of epoxy-functionalized magnetic particles were dispersed In buffer (phosphate buffer, pH 7.4)(5 mL) by sonication. They were separated using a magnet and the supernatant was discarded. Then, a solution of 5.3 mg T10 or R10 in 5mL of the same buffer was added to the magnetic particles. Also a blank sample was prepared by adding 5mL pure buffer. The three samples were incubated over night at RT on a shaker. MALDI TOF analysis of the nanoparticle samples with reference to free peptide demonstrated the successful immobilization (FIG. 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com