Process for isolating cellulose from cellulosic biomass, isolated cellulose of type i and composite materials comprising same

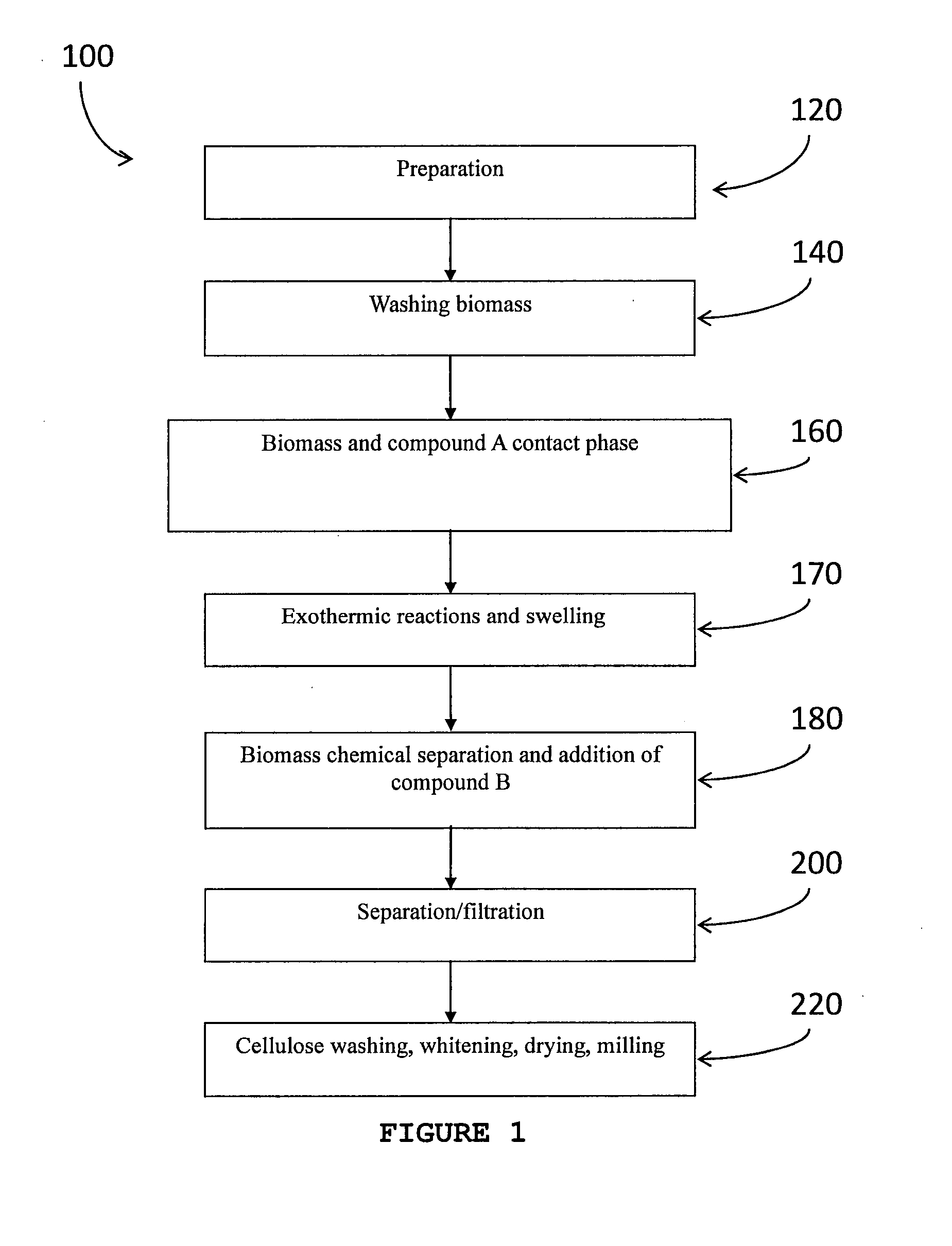

a cellulosic biomass and isolating technology, applied in the field of biomass delignification and cellulose extraction, can solve the problems of high heat and high pressure in the kraft process for several hours, high pollution of both processes, and general undesirable lignin, etc., and achieves the effects of less water, and less water and gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

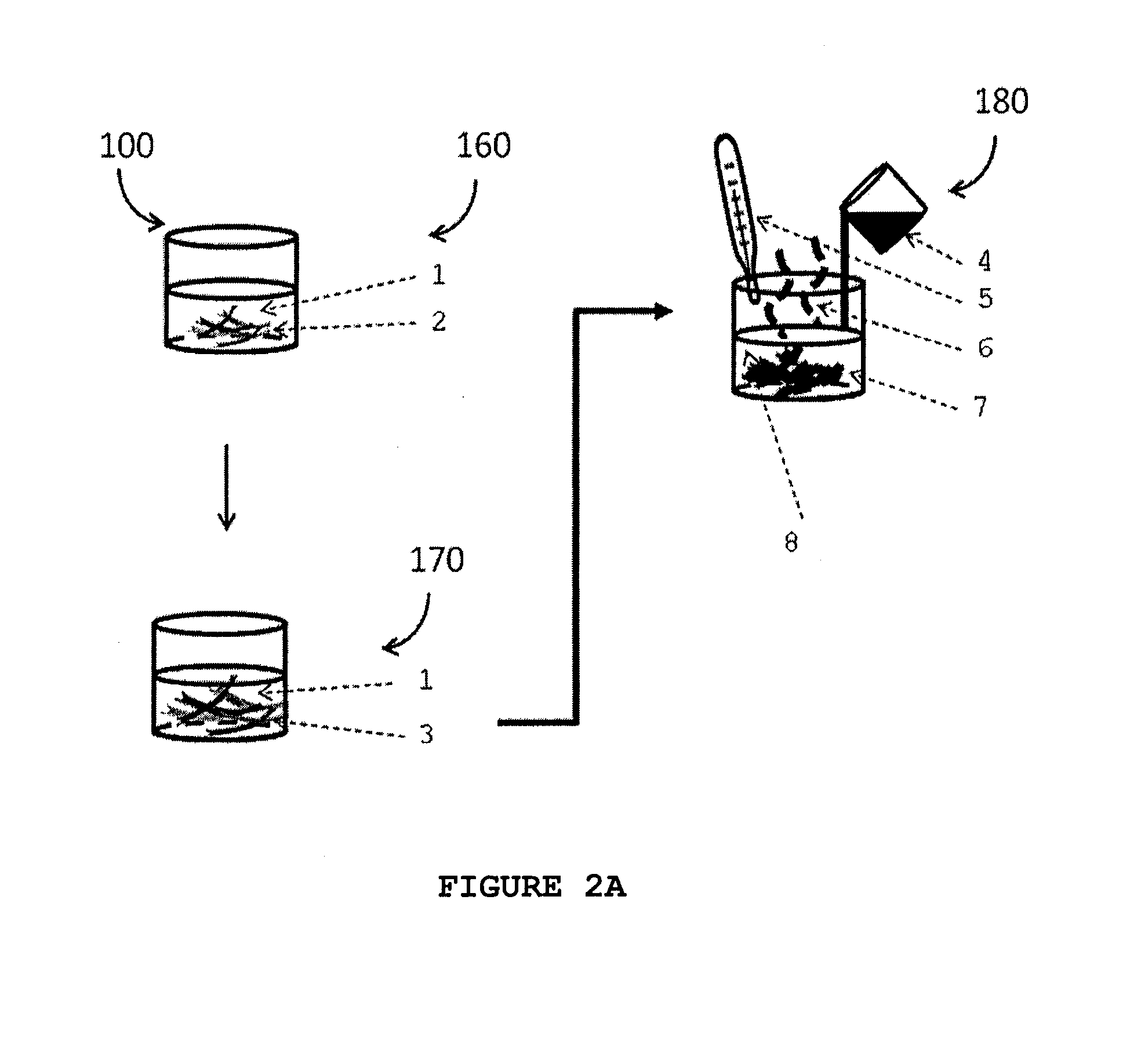

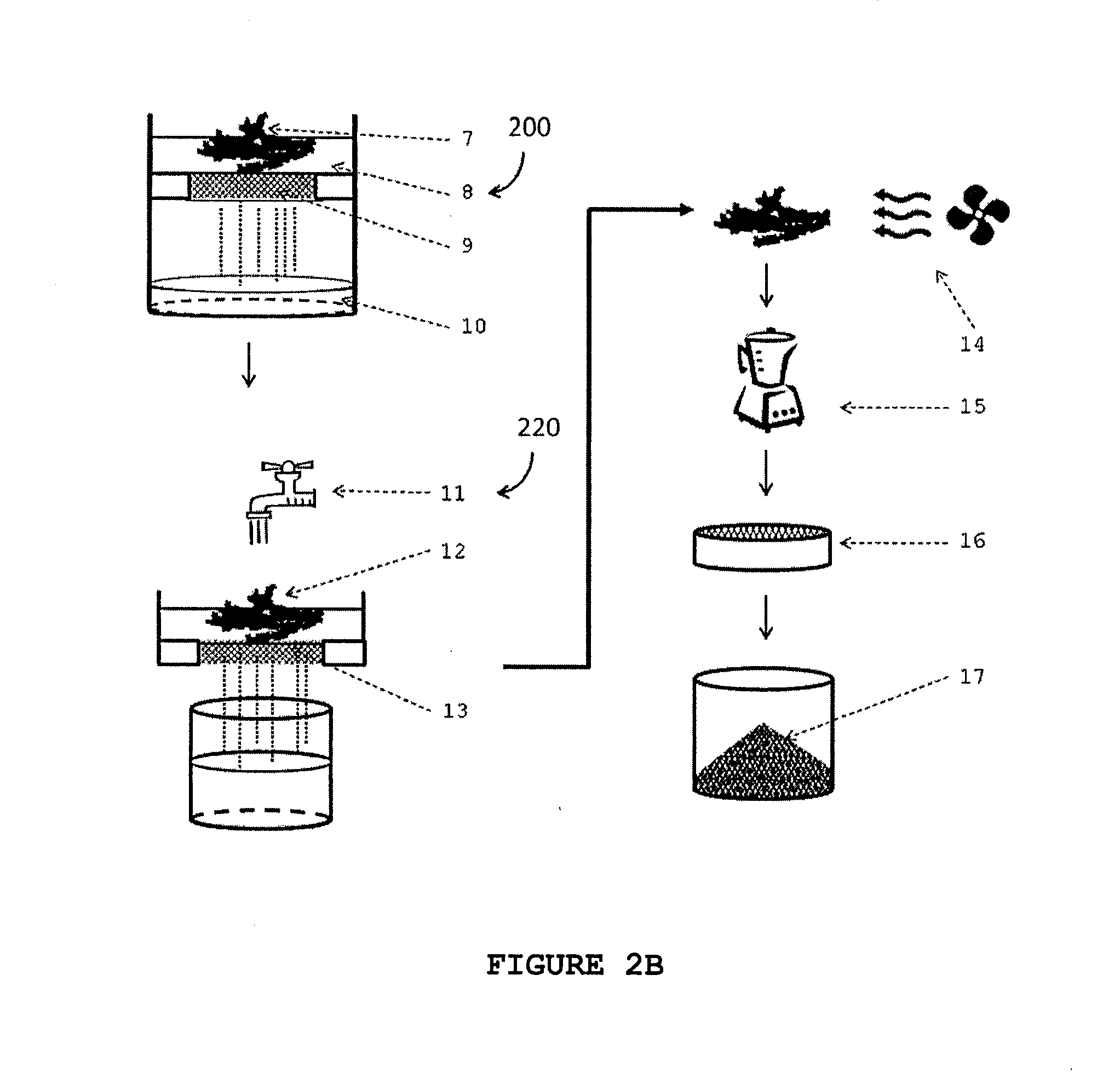

Method used

Image

Examples

examples

[0191]In the following examples, these abbreviations are used:[0192]MXG Mannose, Xylose, Galactose[0193]HMF Hydroxymethylfurfural[0194]HmO Hemicelluloses derivatives and other products[0195]ASL Acid Soluble Lignin[0196]AIL Acid Insoluble Lignin[0197]LI1 2-Aminoethanol[0198]LI2 2,2′-Iminodiethanol[0199]Cel Cellulose[0200]Lig Lignin

examples 1 to 5

Cellulose Extraction from Woody Biomass

[0201]Experimental parameters in all the following examples are described in Table 2 below.

TABLE 2Experimental parameters and resultsExample 1(Control)Example 2Example 3Example 4Example 5NameReferenceLl1 - NO3Ll2 - NO3Ll1 - ClLl2 - NO3(woodchipswithout useof theprocess)Biomass100 g of100 g of100 g of100 g of150 g ofwashedwashedwashedwashedwashedmaplemaplemaplemaplewhite birchwoodchipswoodchipswoodchipswoodchipswoodchipsGradingBetween 20Between 9Between 9Between 20and 80 meshand 20and 20and 80meshmeshmeshCompoundnoneNitric acidNitric acidHydrochloricNitric acidA(H+NO3−)(H+NO3−)acid (H+Cl−)(H+NO3−)200 g200 g200 g200 mlIncubation30 min30 min45 min12 mintime with ACompoundnoneLl1Ll2Ll1Ll2B100 g80 g100 g100 mlIncubation30 min30 min30 min10 mintime with BFinal solidRaw40 g40 g95 g70 gproductwoodchipsCel: 82.5%;Cel: 84.4%;Cel: 57.2%;Cel:(unchanged)Lig: 0.6%;Lig: 1.3%;Lig: 23.9%;1005%HmO:HmO:HmO:16.9%14.2%18.9%

[0202]For each example, the biomass was fi...

example 5

[0209]200 g of white birch wood chips (Betula papyrifera var. papyrifera) were washed with 750 ml of tap water and heated in a microwave oven (max. setting) three times 5 minutes. After a fourth washing with 750 ml of distilled water, the chips were dried at room temperature for 3 days. The chips were then ground to pass through a 10 mesh sieve and left to macerate for an extra 5 to 6 days in two times 1000 ml of distilled ethanol. The washed biomass was again dried at room temperature for 1 more day. The chips were then finely ground and screened to pass through a 18 mesh sieve.

[0210]150 g of washed birch sawdust was put in a well-mixed open batch reactor made of HDPE, displaced under a fume hood. The reactor was settled semi-inclined on a platform, equipped with a bidirectional motor shaft for lateral rotation; 200 ml of concentrated nitric acid (≈70%) was poured on the biomass. The solution was mixed during 12 minutes, allowing some time for impregnation without mixing (≈3 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com