Shoe Sole Focusing on Windlass Mechanism

a technology of windlass and shoe sole, which is applied in the field of shoe sole can solve the problems of limited foot movement, flatfoot and hallux valgus, and conventional techniques that are not focusing on the windlass mechanism and using this mechanism, so as to facilitate the upward displacement of the area, facilitate the arch of the foot, and facilitate the effect of shoe sole flex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

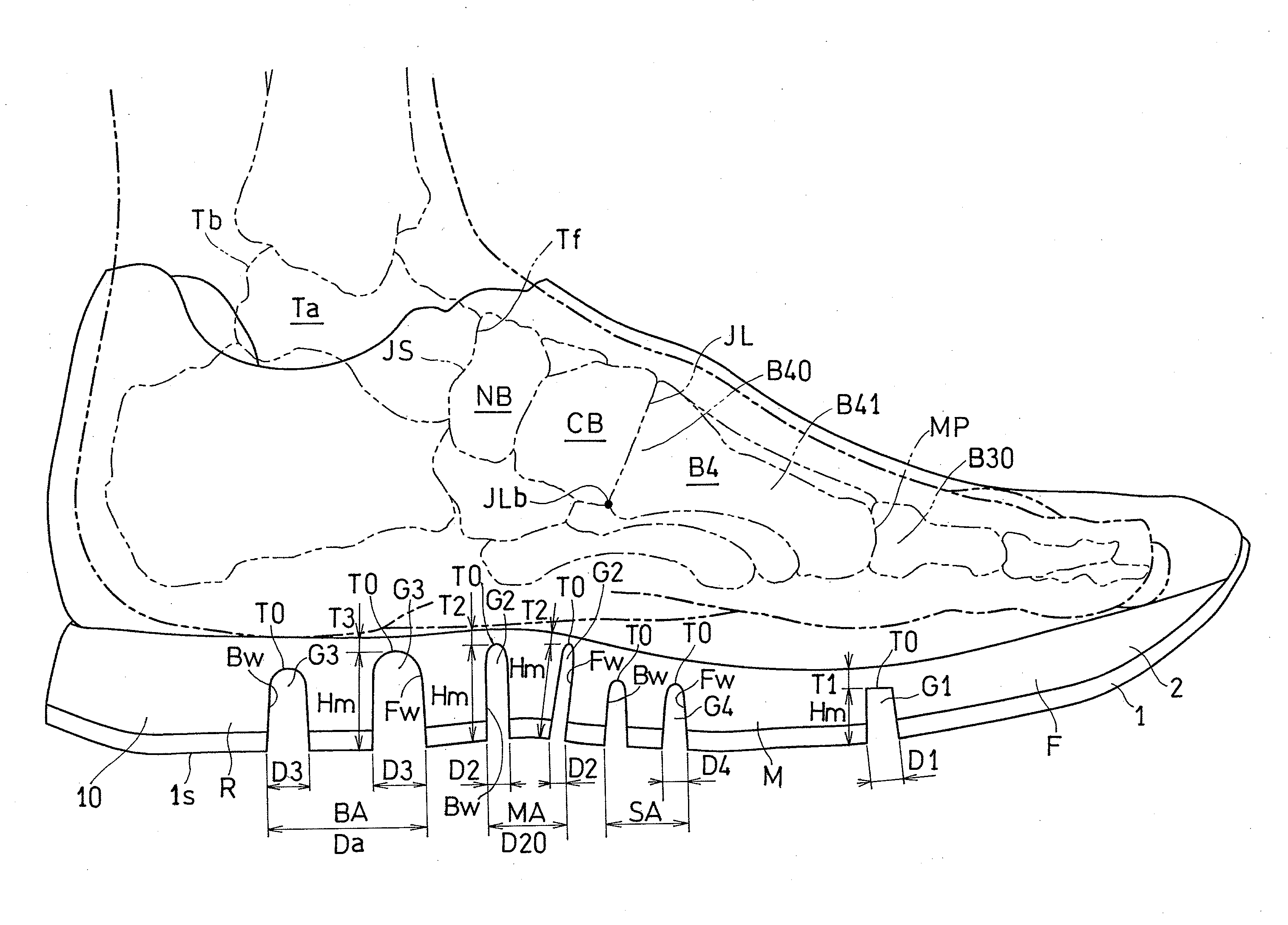

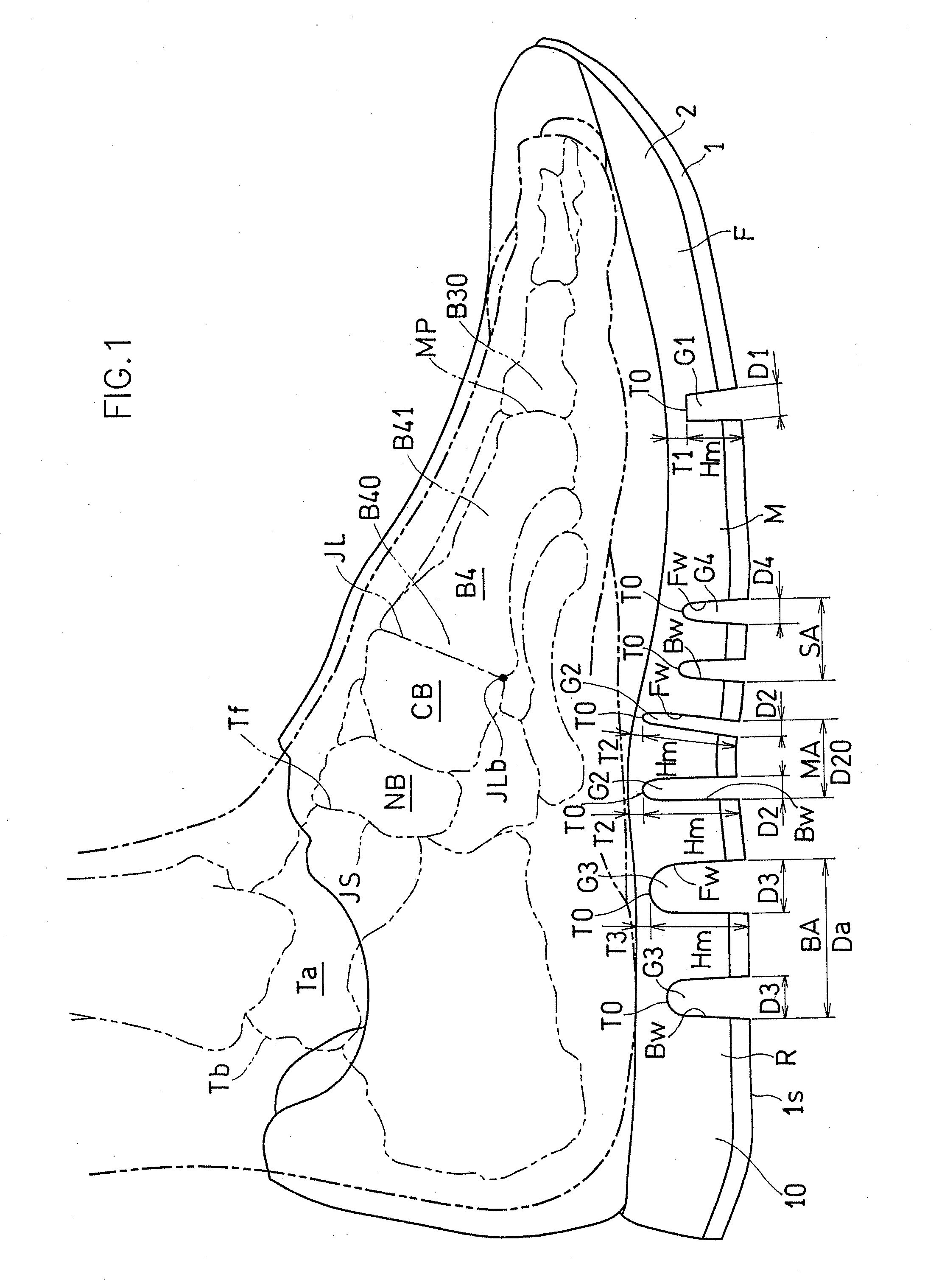

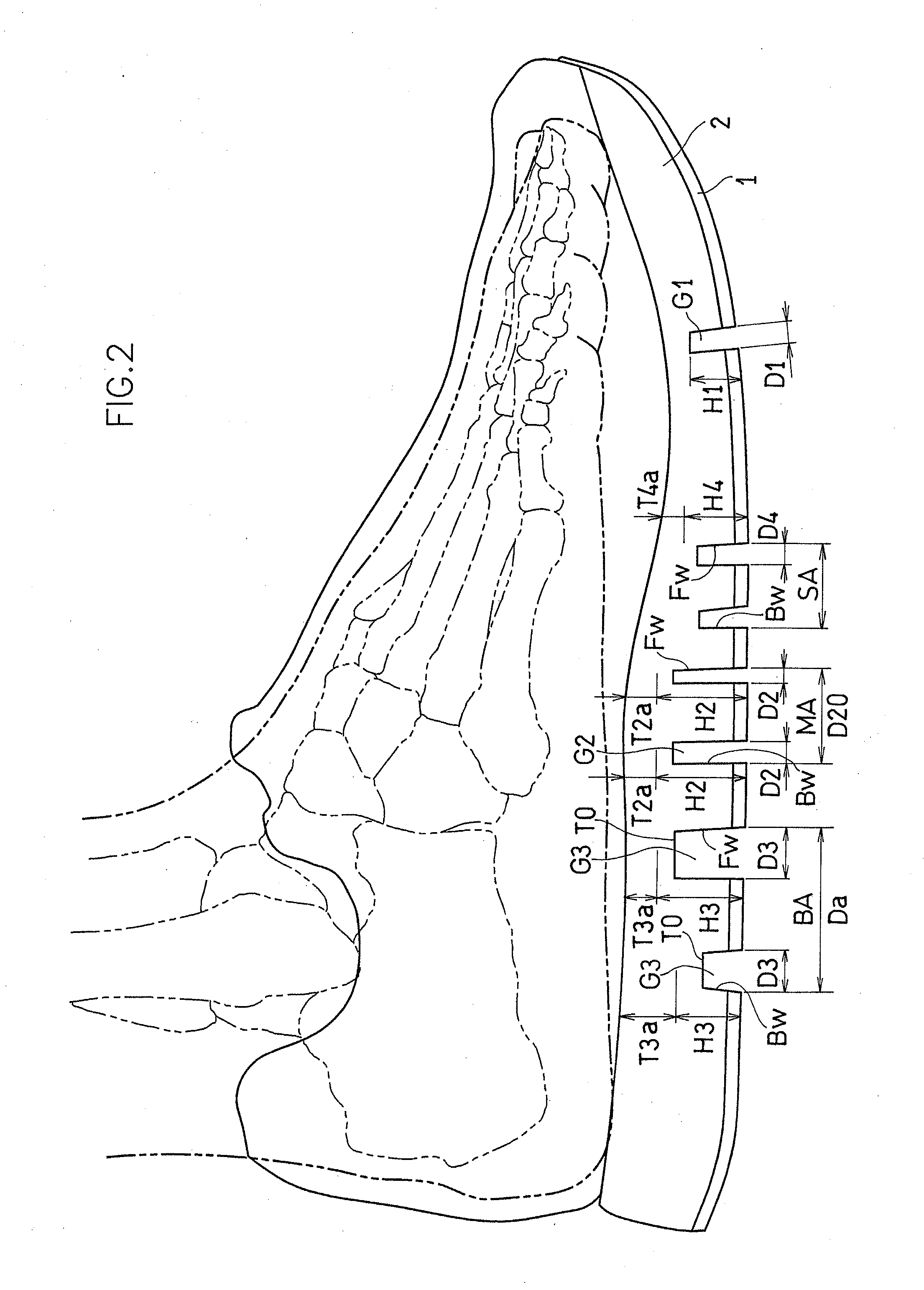

[0095]FIGS. 1 to 4 show Note that in order to facilitate the description of the invention, FIG. 1 shows the medial side of a shoe for the left foot whereas FIG. 2 shows a lateral side view of a shoe for the right foot.

[0096]As shown in FIGS. 1 and 2, a shoe sole includes an outsole 1, and a midsole 2. In various figures, minute grooves (so-called a design) formed on a tread surface 1S of the outsole 1 are omitted.

[0097]In the present embodiment, the outsole 1 and the midsole 2 are placed across the fore foot portion F, the middle foot portion M and the rear foot portion R. The outsole 1 is formed by a foamed or non-foamed rubber, for example, and has the tread surface 1s which has a higher abrasion resistance than the midsole 2 and which is to be in contact with the road surface.

[0098]The midsole 2 is formed by a foamed resin such as EVA, for example, and is placed on the outsole 1, as shown in FIG. 2, for reducing the impact of landing. Therefore, the midsole 2 is formed thicker t...

embodiment 2

[0134]As shown in Embodiment 2 of FIG. 5, some or all of the second to fourth transverse grooves G2 to G4 may be set to a length such that they extend from the medial edge 10 toward the lateral edge 11 past the longitudinal axis A1 but do not reach the lateral edge 11. The arch of the foot is high on the medial side, and the effect of the windlass mechanism can be therefore expected as long as the medial side portion of the sole can flex sufficiently.

[0135]Preferably, the transverse grooves G1 to G4 can extend over about ⅔ the total width from the medial edge 10 to the lateral edge 11 in the area where the transverse grooves G1 to G4 are provided.

[0136]Note that as opposed to the example shown in FIG. 5, the second and third transverse grooves G2 and G3 may be provided across the total width, whereas the first and fourth transverse grooves G1 and G4 are provided so as to extend from the medial edge 10 past the longitudinal axis A1 and into a part of the lateral side portion.

[0137]As...

embodiment 3

[0138]In Embodiment 3 of FIG. 6, there may be a single, i.e., only one, second transverse groove G2 that is deeper than the third transverse groove G3. In this example, the depth of a second transverse groove G2 that is immediately anterior to the posterior second transverse groove G2 is smaller than the depth of one of the third transverse grooves G3.

[0139]Where there is one second transverse groove G2 that is deeper than the third transverse groove G3, as in this example, at least the ceiling TO of the second transverse groove G2 is preferably placed directly below the navicular bone NB. This is because the navicular bone NB is located at the apex of the arch of the foot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com