Additives for self-regeneration of epoxy-based coatings

a technology of epoxy-based coatings and additives, applied in coatings, inks, applications, etc., can solve the problems of low mechanical strength of coatings, damage caused by mechanical action, and difficulty in protecting microcapsules, so as to prevent corrosion propagation, ensure the integrity of microcapsules, and promote stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

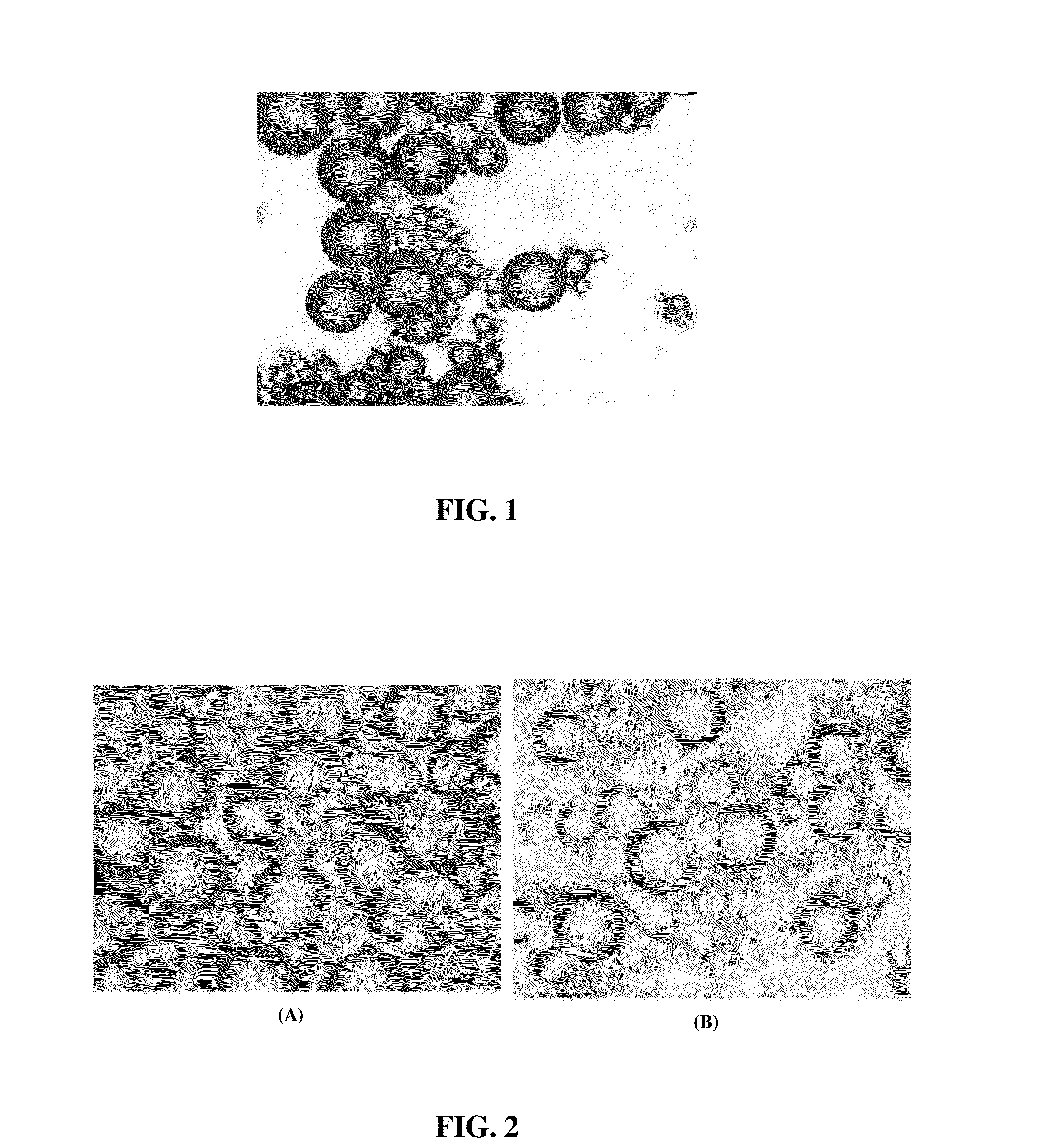

[0028]The following example illustrates the preparation of the preparation of microcapsules containing linseed oil as repairing agent in concentrations between 10% to 15% by weight, additived with drying agents, using acacia gum as surfactant in a concentration in the range of 0.1% to 0.5% by weight.

[0029]In a beaker, the repairing agent, water and surfactant are added, controlling speed of agitation in the range of 800 rpm to 3000 rpm during the formation of the emulsion to ensure the stability of the emulsion and to provide constant medium homogenization.

[0030]In a later step, after the addition of monomers and hardening agents, the agitation speed is reduced to the range of 100 rpm to 500 rpm so as to facilitate polymerization and to obtain uniform microcapsules.

[0031]Table 1 below illustrates a possible composition of the additives described in this invention.

TABLE 1COMPONENTRange % (by weight)Urea1-3Formaldehyde 37 m %3-5Ammonium chloride0.1-0.2Resorcinols0.1-0.2Sodium chloride...

example 2

[0032]The following example illustrates the stability of additives composed of microcapsules containing the repairing agent when dispersed in an organic solvent, specifically a commercial solvent for high solids content epoxy based corrosion resistant coatings in liquid form.

[0033]Microcapsules prepared in accordance with the method described in example 1 were dispersed in solvent thus obtaining a fully stable dispersion, in that the integrity of the microcapsules is maintained during application, a very important parameter to avoid migration of the repairing agent through their walls.

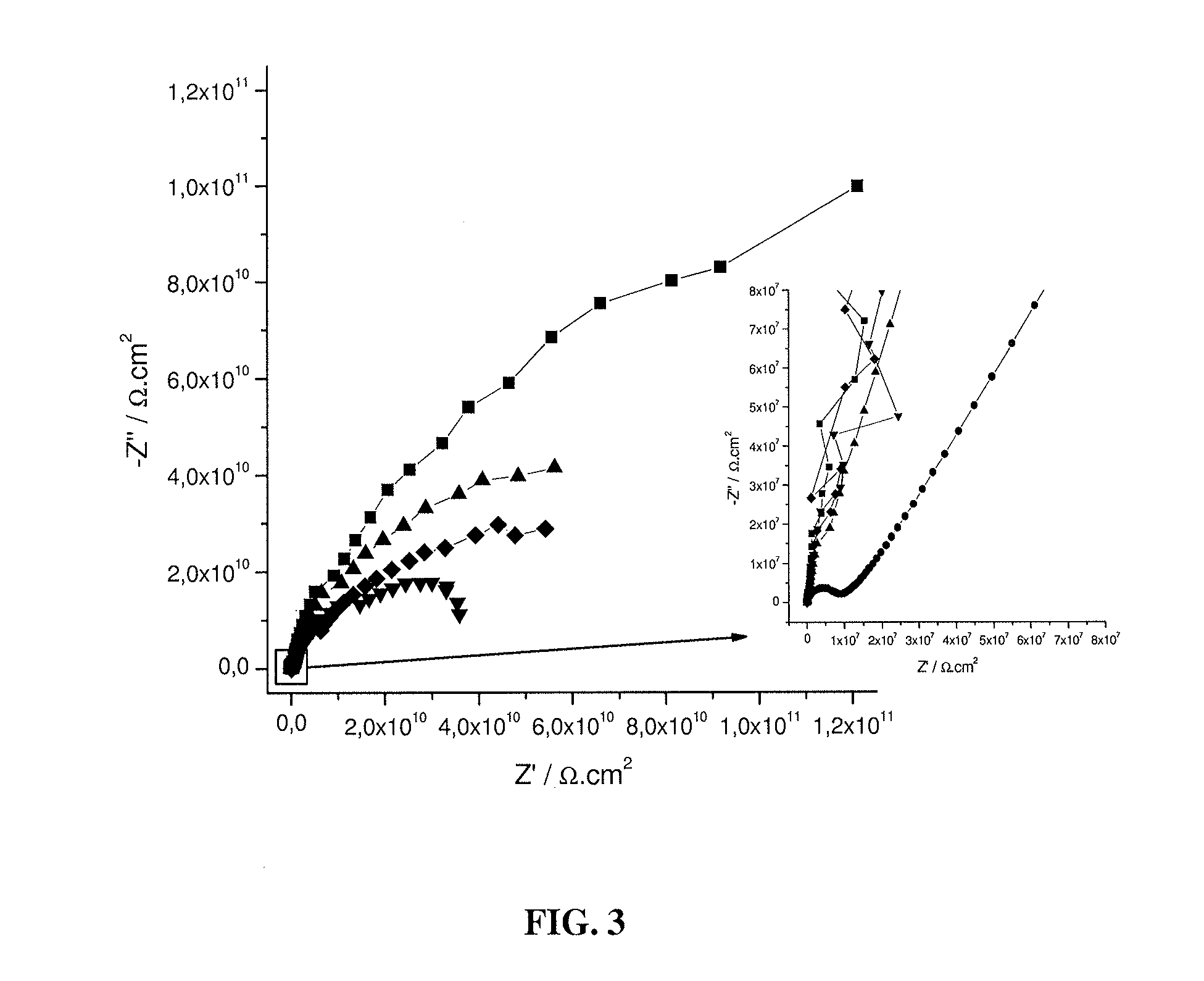

[0034]FIG. 3 illustrates the obtained dispersion containing 60% of microcapsules and 40% of paint solvent after one day of preparation (FIG. 3A) and after fifteen days (FIG. 3B) of conditioning in wet film, showing good dispersion stability. The dispersion stability is very important for use in paints with high solids content.

example 3

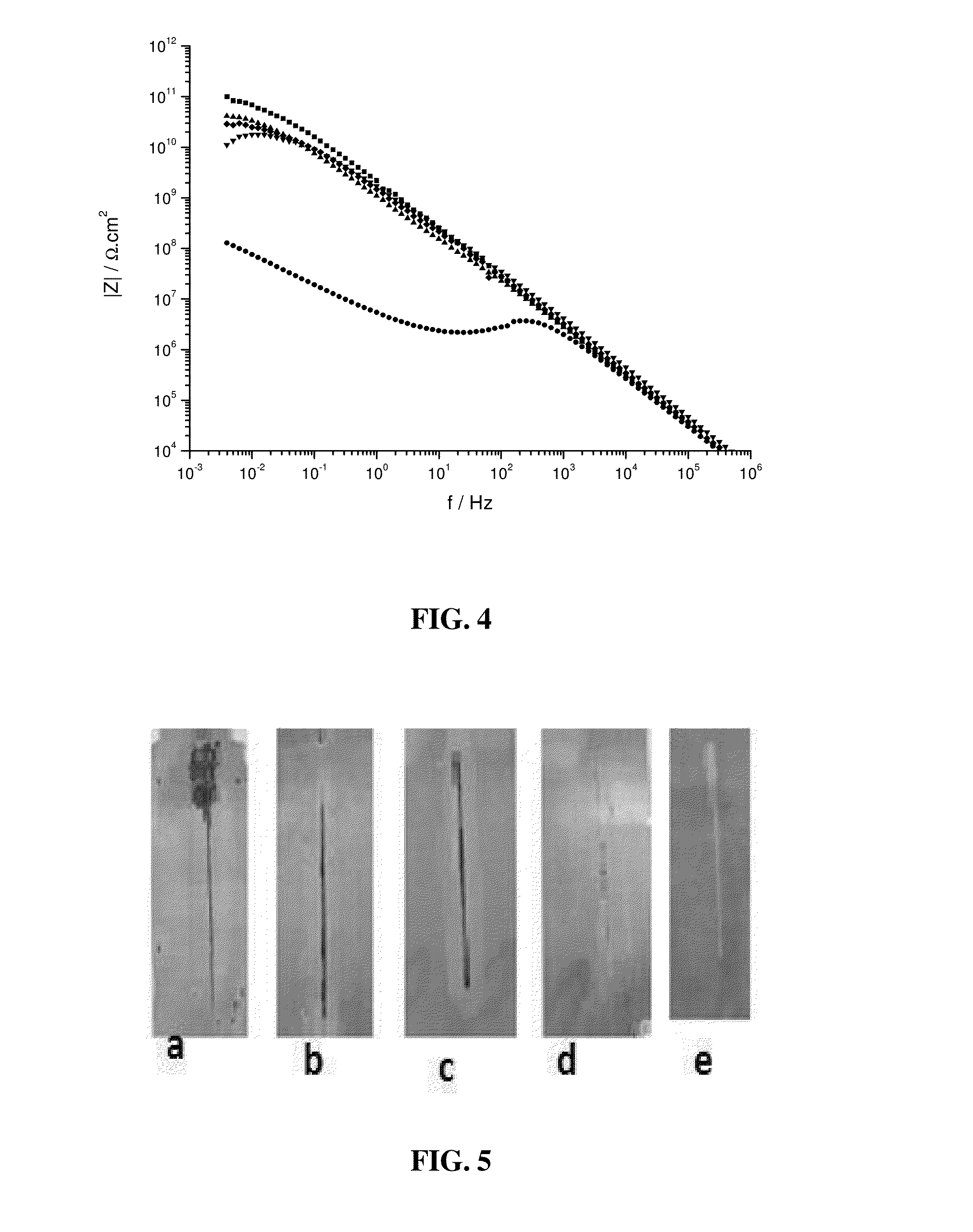

[0035]The following example illustrates the use of additives prepared according to example 2 in the formulation of high solids content epoxy based corrosion resistant coatings in liquid form.

[0036]From the dispersion containing the microcapsules obtained according to example 2 and the addition of those at a concentration of 5% to 20% (by weight) in wet base to high solids content epoxy based corrosion resistant coatings in liquid form; specimens were painted with a thickness in the range of 500 microns, using different dispersion / solvent mix compositions whose dry layer thickness and quantity of capsules in wet base are illustrated in Table 2 below.

TABLE 2Amount ofAmount of wetdispersion (capsule +based capsulesDry layerSpecimensolvent) % (m / m)% (m / m)thickness μmCp100477 ± 19Cp2106.4478 ± 25Cp32012.8491 ± 27

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com