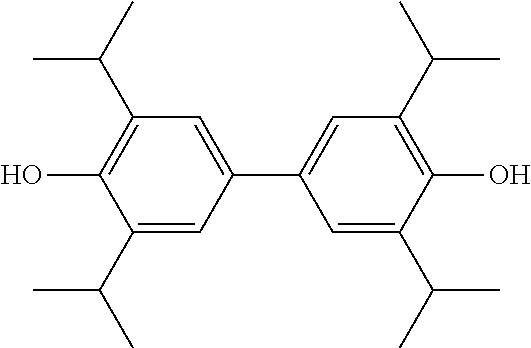

2,2',6,6'-tetraisopropyl-4,4'-biphenol lipid microsphere preparations and preparation methods therefor

a technology of tetraisopropyl and lipid microspheres, which is applied in the field of pharmaceutical preparations, can solve the problems of difficult water dissolution of tetraisopropyl-4,4'-biphenol, limited clinical application, and affect the efficacy, so as to improve the therapeutic effect of the drug and improve the absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

1% Biphenol Lipid Microsphere Preparation

[0046]

Drugs and ExcipientsAmount (g)Biphenol10.0Soybean oil (Injection-grade)100Egg lecithin12Vitamin E10Glycerin25EDTA5Injection-grade waterMake up to 1000 ml

Preparation Method

[0047]1) 12 g of egg lecithin was completely dissolved in 100 g of injection-grade oil under a nitrogen atmosphere and in a 70° C. water bath. 10 g of biphenol and 10 g of vitamin E were then added and nitrogen gas was fed in for protection before being dissolved, with heat and stirring, to obtain an oil phase.

[0048]2) 20 g of glycerin and 5 g of EDTA were dissolved, with stirring, in the injection-grade water to obtained an aqueous phase.

[0049]3) The oil phase was added slowly to the aqueous phase while sheared under nitrogen (10000 r, 5 min) to obtain a preliminary emulsion which was then adjusted to around pH 8.0 with sodium hydroxide.

[0050]4) The preliminary emulsion was homogenized with a high-pressure homogenizer and filtered with a microporous membrane filter be...

example 2

0.1% Biphenol Lipid Microsphere Preparation

[0051]

Drugs and ExcipientsAmount (g)Biphenol1.0Sea buckthorn oil (Injection-100grade)Hydrogenated Lecithin12Ascorbic acid10Glycerin25EDTA5Injection-grade waterMake up to 1000 ml

Preparation Method

[0052]1) 12 g of hydrogenated lecithin was completely dissolved in 100 g of injection-grade oil under a nitrogen atmosphere and in a 70° C. water bath. 1 g of biphenol was then added and nitrogen gas was fed in for protection before being dissolved, with heat and stirring, to obtain an oil phase.

[0053]2) 25 g of glycerin, 10 g ascorbic acid and 5 g of EDTA were dissolved, with stirring, in the injection-grade water to obtain the aqueous phase.

[0054]3) The oil phase was added slowly to the aqueous phase while sheared under nitrogen (10000 r, 5 min) to obtain a preliminary emulsion which was then adjusted to around pH 8.0 with sodium hydroxide.

[0055]4) The preliminary emulsion was homogenized with a high-pressure homogenizer and filtered with a microp...

example 3

3% Biphenol Lipid Microsphere Preparation

[0056]

Drugs and ExcipientsAmount (g)Biphenol30Injection-grade Medium-chain100triglyceride oilSoy lecithin12Sodium bisulfite10Glycerin25EDTA5Injection-grade waterMake up to 1000 ml

Preparation Method

[0057]1) 12 g of soy lecithin was completely dissolved in 100 g of injection-grade oil under a nitrogen atmosphere and in a 70° C. water bath. 30 g of biphenol was then added and nitrogen gas was fed in for protection before being dissolved, with heat and stirring, to obtain an oil phase.

[0058]2) 25 g of glycerin, 10 g of sodium bisulfite and 5 g of EDTA were dissolved, with stirring, in the injection-grade water to obtained an aqueous phase.

[0059]3) The oil phase was added slowly to the aqueous phase while sheared under nitrogen (10000 r, 5 min) to obtain a preliminary emulsion which was then adjusted to around pH 8.0 with sodium hydroxide.

[0060]4) The preliminary emulsion was homogenized with a high-pressure homogenizer and filtered with a micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com