Methods for producing melanin and inorganic fertilizer from fermentation leachates

a technology of inorganic fertilizer and melanin, which is applied in the direction of peptides, peptide sources, invertebrate treatment, etc., can solve the problems of poor sugar and starch content, less value, and accumulation in the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

6.1. Example 1

First Embodiment of Method for Producing Natural Melanin and / or Melanin-Associated Proteins from Fermentation Leachates

[0168]This example describes one non-limiting embodiment of the method.

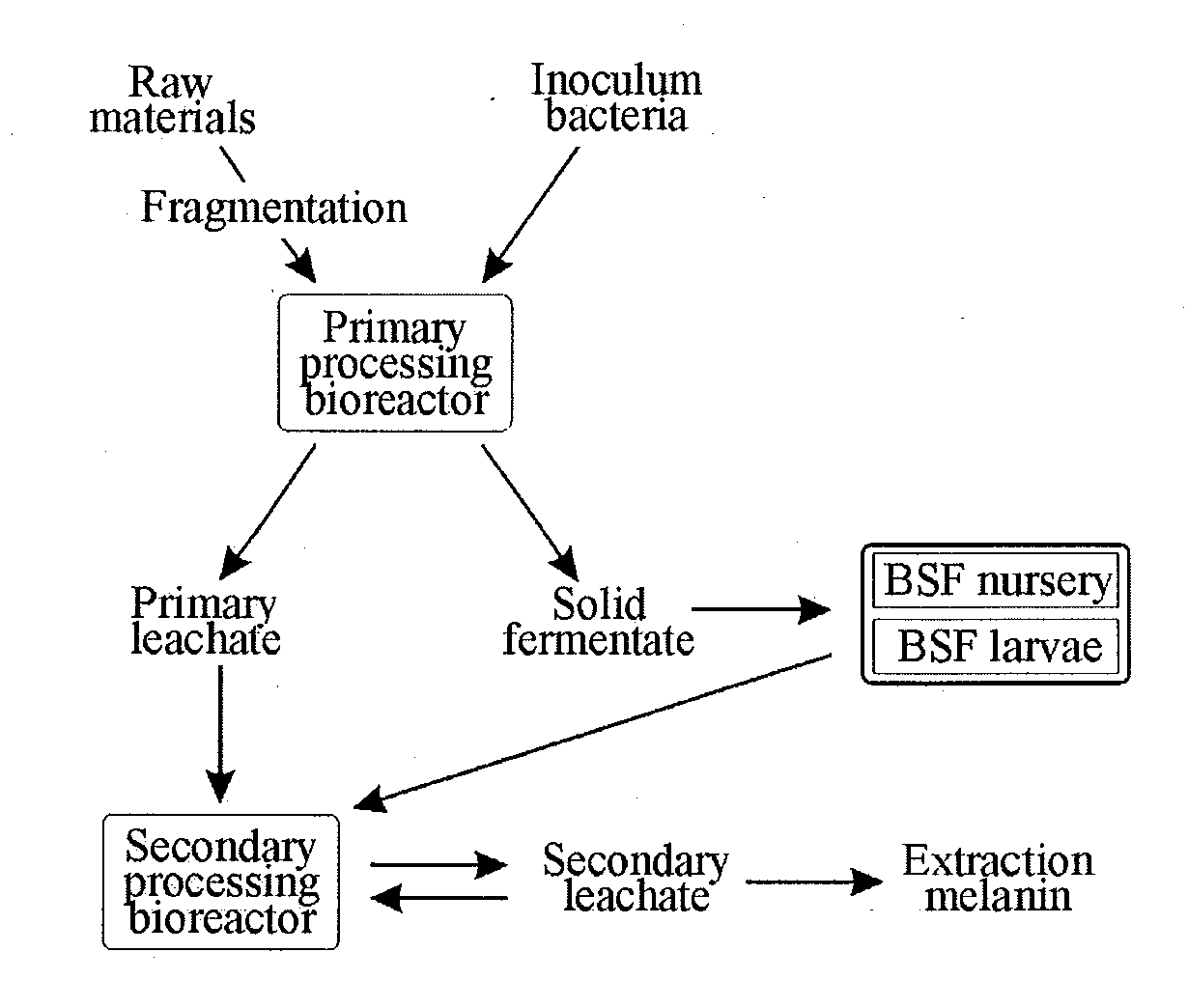

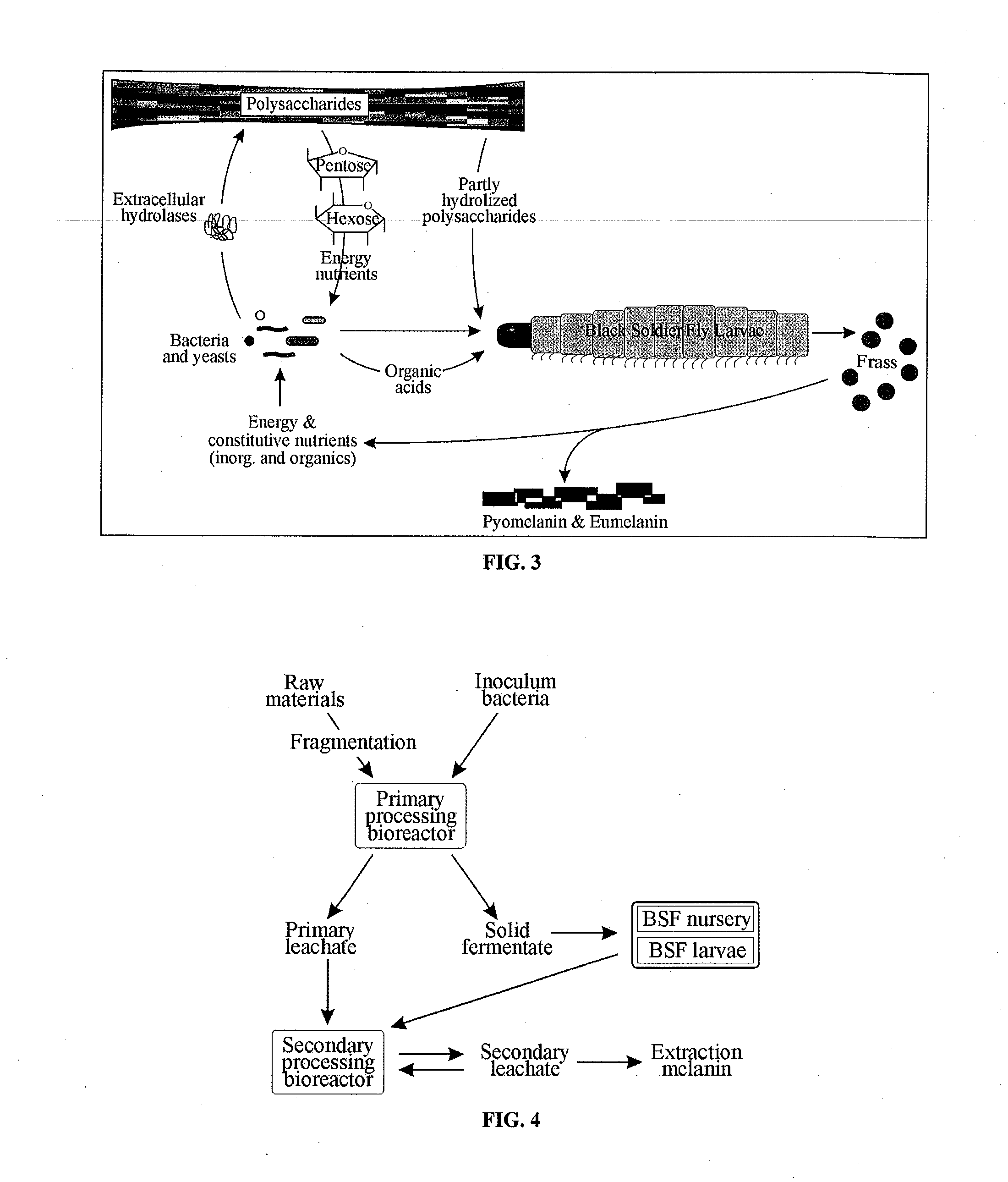

[0169]BSFL are propagated in a nursery (such as shown in FIG. 2). In the nursery, the BSFL are grown to a larval stage where they are tough enough to withstand high density, chemical stress and nutrient starvation, i.e., about 5-7 days old and approximately 0.5 cm long. BSFL are then separated from their initial food source in the nursery and mixed in an incubator, referred to herein as a secondary processing bioreactor, with fermentation (primary) leachates derived from primary processing in a primary processing bioreactor. Air is continuously provided, e.g., with a pump to provide O2 to the larvae, to remove toxic volatile chemicals (such as ammonia, organic amines and sulfide) and to help microbial respiration.

[0170]In a preferred aspect, the temperature at which the BSFL are mai...

example 2

6.2. Example 2

Second Embodiment of Method for Producing Natural Melanin and / or Melanin-Associated Proteins from Fermentation Leachates

[0181]This example describes another non-limiting embodiment of the method.

[0182]1. Producing the Primary Leachate[0183]a) Anaerobic / microaerobic fermentation of food waste and cellulosic residues is carried out in the presence of mixed microbial cultures dominated by species of Clostridium and / or Lactobacillus. The mixed cultures come from inoculums produced in the lab by fermenting a wheat culture medium with microorganisms obtained from earlier fermentations. Fermentation is conducted in primary processing bioreactor.[0184]b) The chemical composition of the primary leachate is continuously monitored. The primary leachate is drained from the primary processing bioreactor when the pH is about 3.4-4.0 and stored at room temperature in closed containers in the absence of air.[0185]c) More water is added to the primary processing bioreactor and the prim...

example 3

6.3. Example 3

Method for Producing Pyomelanin-Enriched Melanin from Organic Waste Using Microorganisms and Black Soldier Fly Larvae

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com