Hydraulic Radial-piston Pump for Wind Turbines

a radial piston and wind turbine technology, applied in the direction of pump components, piston pumps, positive displacement liquid engines, etc., can solve the problems of high cost, reduce the efficiency of the piston assembly, and consume space, so as to reduce friction and compression losses, reduce friction and wear, and minimize friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

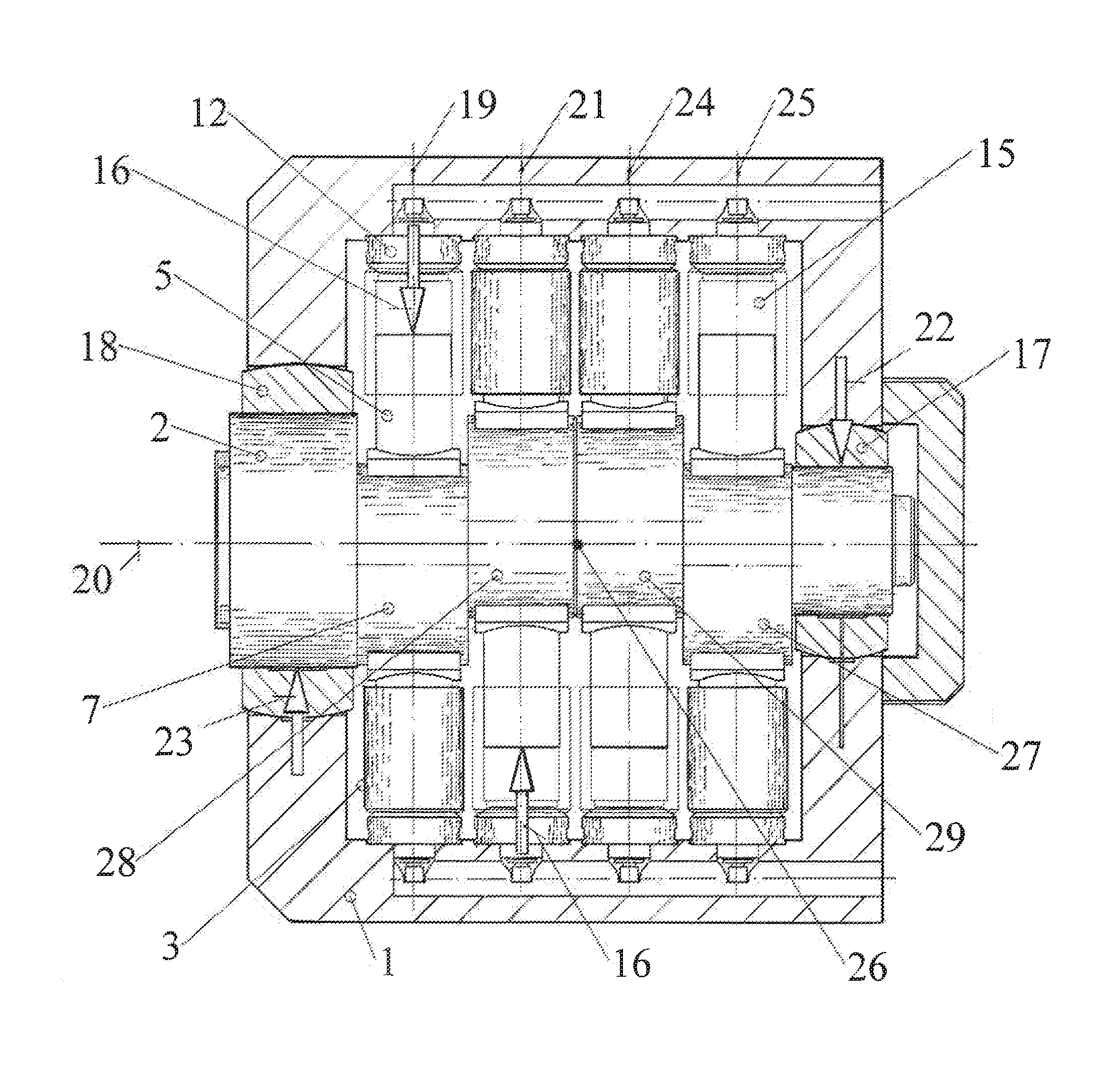

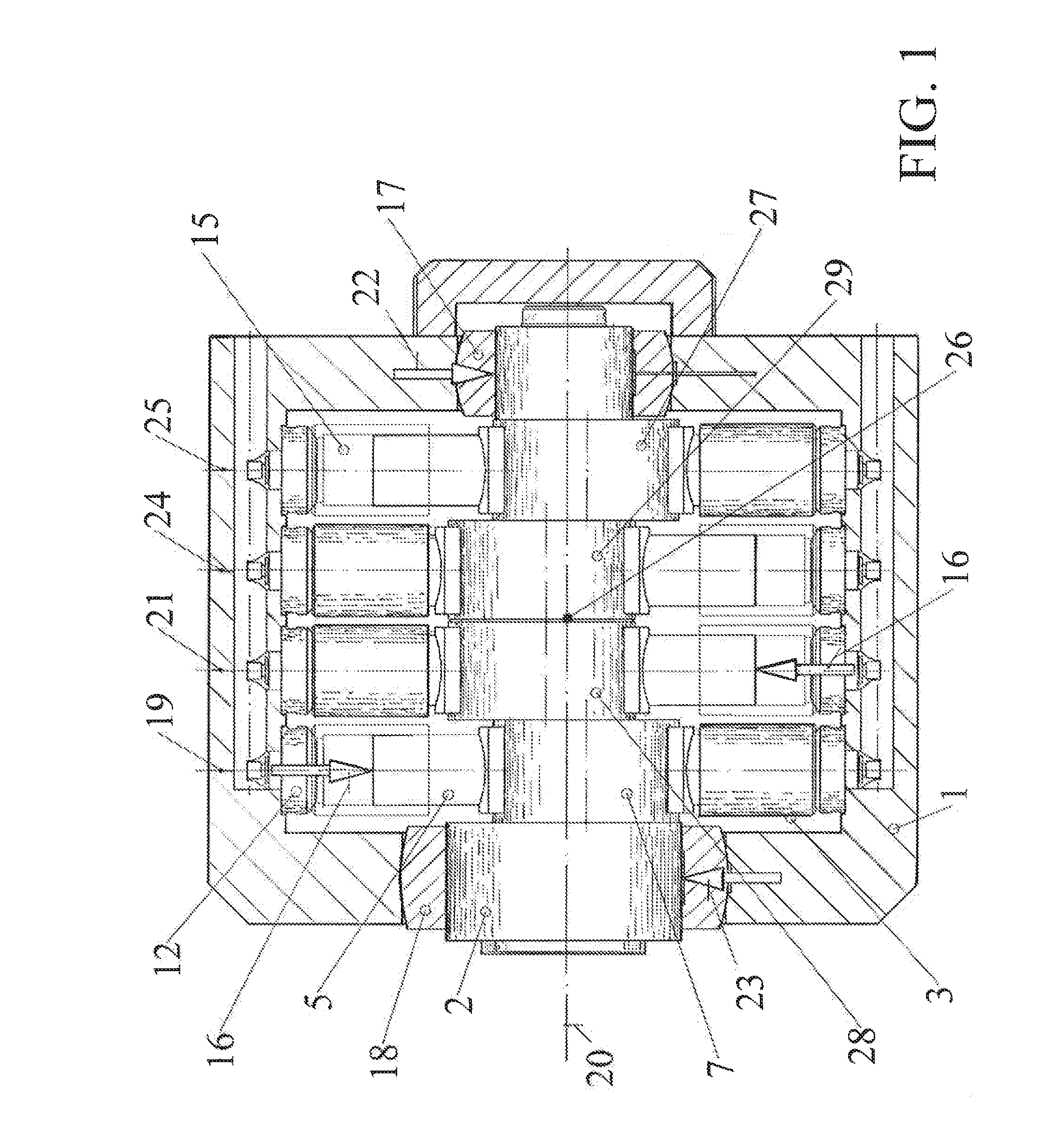

[0021]The new pump (FIG. 1) consists of housing 1, a centrally located camshaft 2 and cylinder assemblies 3 located in radial direction between camshaft and housing.

[0022]Rotation of the camshaft, results in a reciprocating movement of the piston within the cylinder, creating a pumping action.

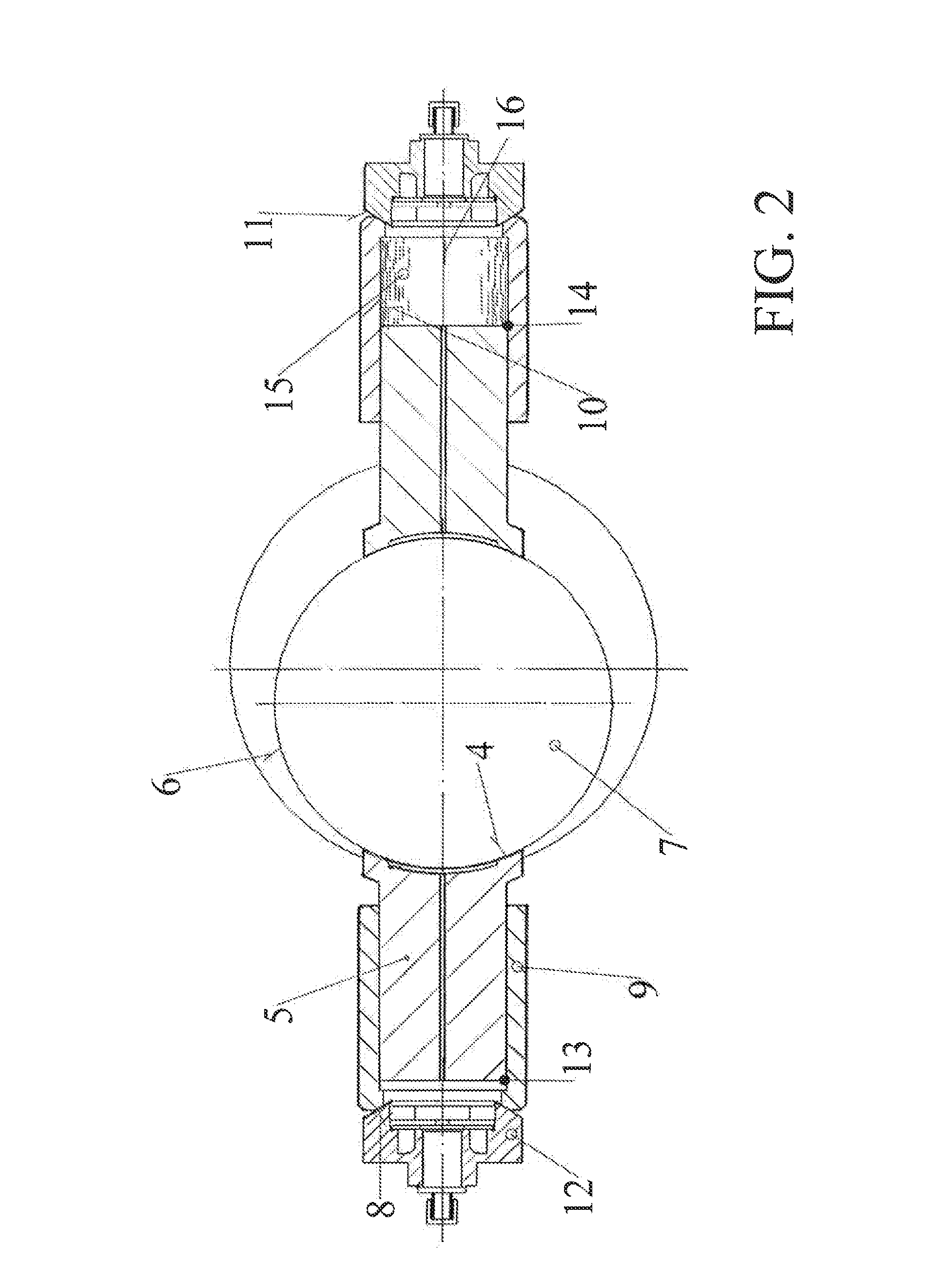

[0023]The cylindrical face 4 (FIG. 2) of piston 5 is in sliding contact with the cylindrical face 6 of cam 7 of the camshaft.

[0024]The spherical face 8 of the cylinder 9 at the opposite end of the cylinder bore 10 is in sliding contact with the spherical face 11 of cylinder joint 12.

[0025]The pivotal movement of cylinder 9 allows for a self-adjustment of cylindrical face 4 of the piston to the cylindrical face 6 of the cam shaft, significantly reducing leakage, friction, and wear.

Piston Force Compensation

[0026]The cam 7(FIG. 2) advances the piston from Bottom End Position (BEP) 13 to Top End Position (TEP) 14, and piston chamber 15 receives fluid through cylinder joint 12 during the first half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com