Tilt minimization through intensity control of light source

a technology of intensity control and light source, applied in the field of optical metrology, can solve the problem that the detector cannot experience total saturation during the process of finding focus, and achieve the effect of removing the tilt of the sampl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The term “image depth,” as used herein, is intended to refer to the range of scanner positions within which the image of the sample is visible during a vertical scan of an interferometer. The term “depth of focus” refers to the range of scanner positions within which the sample is in focus during the vertical scan of the interferometer. The term “depth of fringes” refers to the range of scanner positions within which interferometric fringes produced by the sample are visible during the vertical scan of the interferometer.

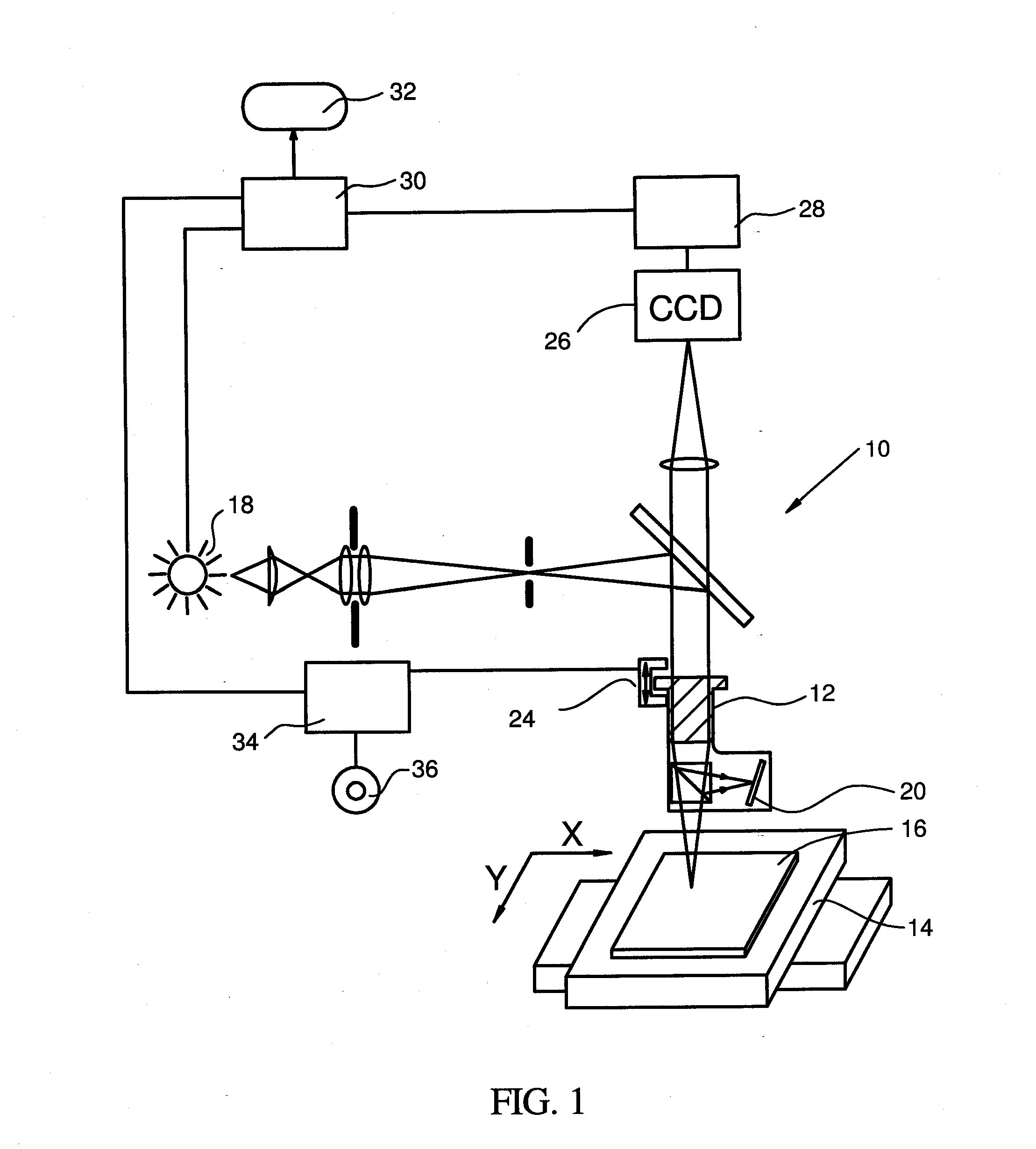

[0018]Referring to the figures, wherein like parts are referenced with the same numerals and symbols, FIG. 1 represents schematically a Z-scanning interferometer 10 with a microscope objective 12 and a sample stage 14 capable of relative translation in the X and Y plane (in a single direction, or in serpentine or raster fashion, as the need may be) to acquire images of multiple portions of a sample surface 16. As used herein, X and Y refer to the plane coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com