Automatic double-station rapid sample milling device

A double-station, fully automatic technology, applied in the direction of milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of poor fixture structure reliability, lower sample processing quality, easy to scratch test personnel, etc., to eliminate workpiece tilt , Improve processing quality and detection accuracy, facilitate operation and observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

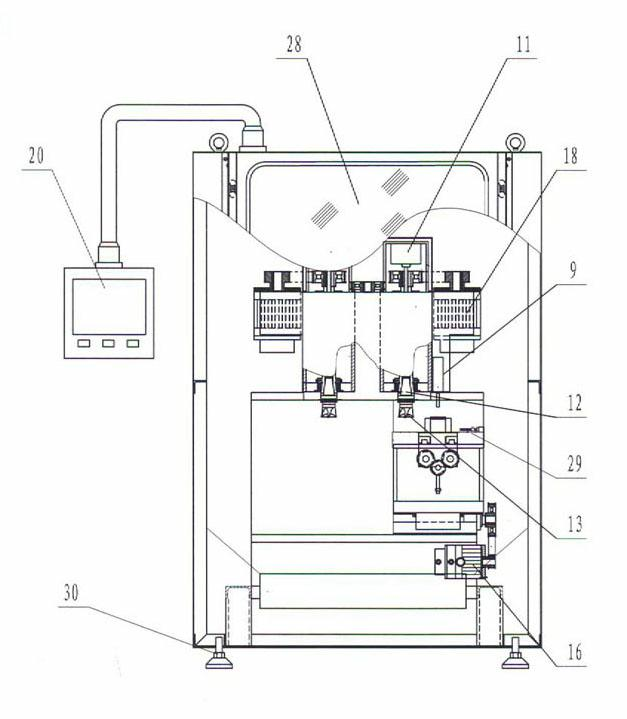

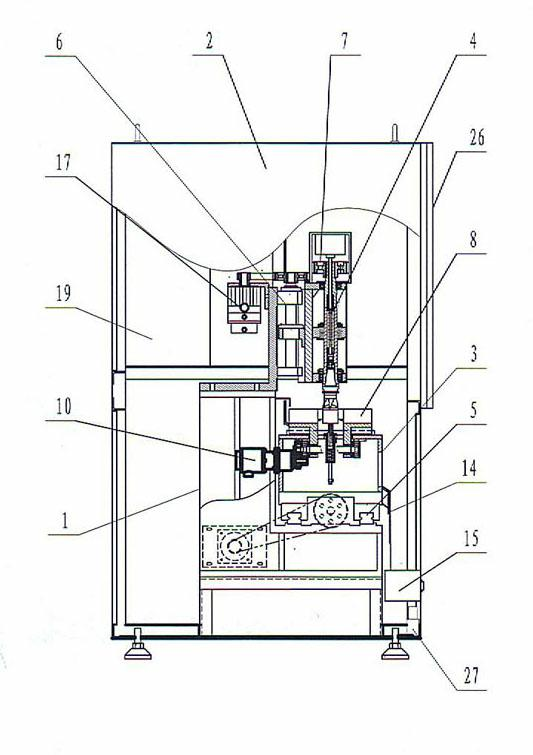

[0014] Embodiment 1: as figure 1 and figure 2 As shown, the full-automatic double-station fast milling prototype includes bed 1, box body 2, workbench 3, spindle device 4, X-axis guide rail 5, Y-axis screw rod 6, timing pulley 7, clamping device 8, Positioning cylinder 9, clamping air motor 10, tool change cylinder 11, cutter bar 12, cutter head 13, dust cover 14, cutting receiving hopper 15, X-axis servo motor 16, lifting servo motor 17, rotating servo motor 18, PLC Electric control box 19, touch screen 20, automatic sliding door 26, sliding door cylinder 27, dust blowing air pipe 29, dust blowing gun and adjusting feet 30, X-axis guide rail 5 is connected with X-axis servo motor 16, Y-axis screw rod 6 is connected with lifting The servo motor 17 is connected, the spindle device 4 is connected with the rotary servo motor 18, the clamping air motor 10, the tool change cylinder 11, the X-axis servo motor 16, the lifting servo motor 17 and the rotary servo motor 18 are respect...

Embodiment 2

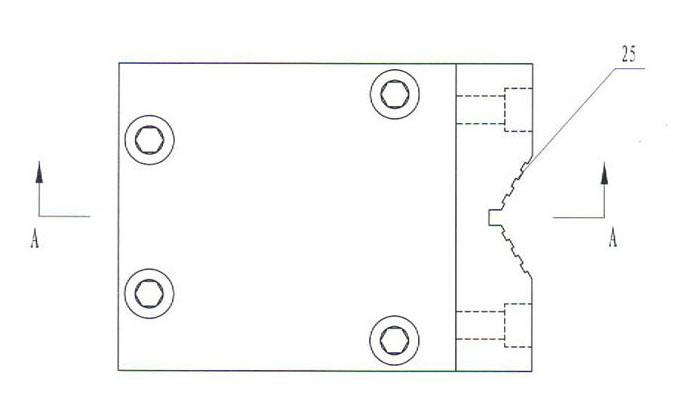

[0015] Embodiment 2: as image 3 and Figure 4 As shown, the clamping device 8 includes a clamp base 21, a jaw 22, a fixing screw 23 and a force buckle 24, the clamp base 21 and the jaw 22 are connected by a fixing screw 23, and a groove 25 is provided on the clamp base 21 for fixing The reinforcing buckle 24 is buckled in the groove 25, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com