Full-automatic chaff hot-blast stove

A fully automated, hot blast stove technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of not achieving the expected effect, not having a fully automated 1.5 million kcal biomass hot blast stove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

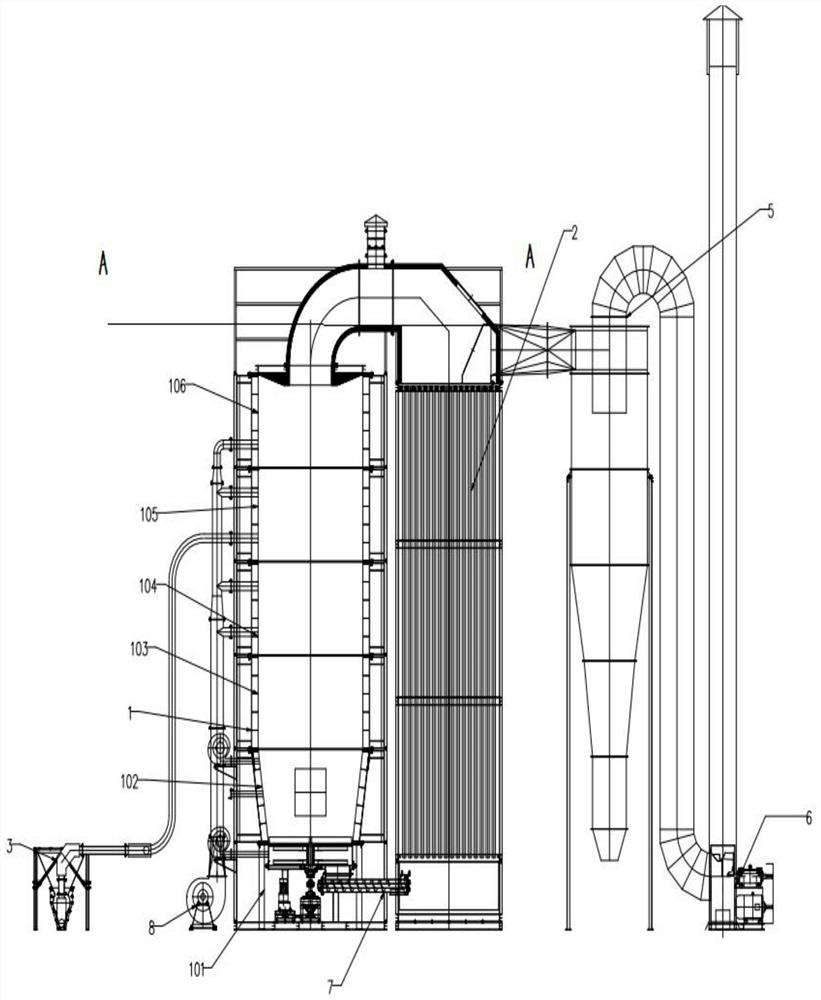

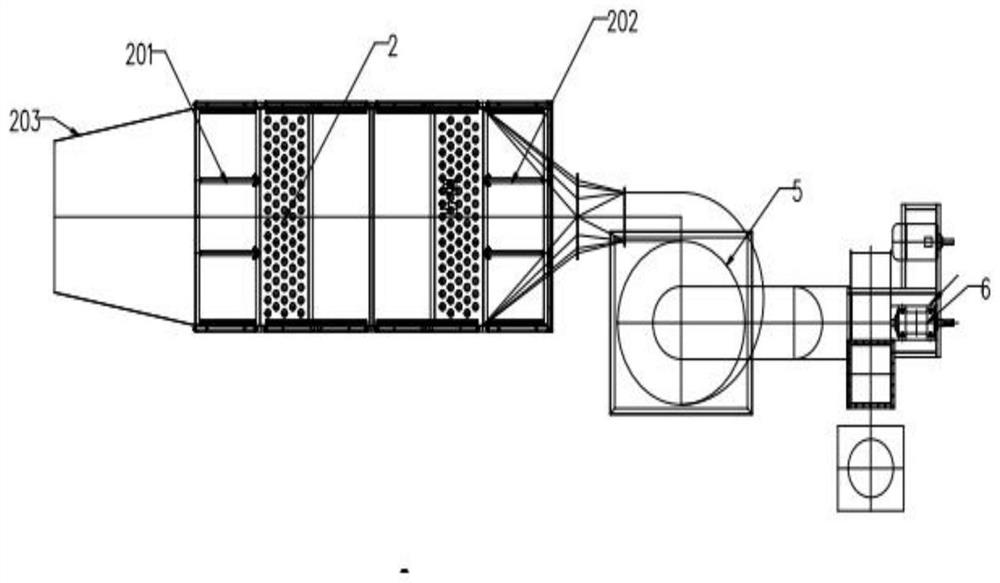

[0038] see Figure 1-Figure 6 , the present invention provides a technical solution: a fully automatic hot blast stove for coarse bran, comprising a combustion chamber 1 and a heat exchanger 2, the left side of the combustion chamber 1 is provided with a feed lifting device 3, and the right side of the combustion chamber 1 is provided with a feed lifting device 3. There is an automatic ash removal device 4 on the side, a centrifugal dust removal device 5 on the right side of the heat exchanger 2, the combustion chamber 1, the heat exchanger 2, the feed lifting device 3, the automatic ash removal and ash removal Device 4 and centrifugal dust removal device 5 are controlled by PLC+PID intelligent control system.

[0039] The heat exchanger 2 is made of Q235 steel heat exchange tubes, and the heat exchanger 2 is made of Q235 steel heat exchange tubes. The left side of the heat exchanger 2 is provided with an air inlet 201, and the air inlet 201 communicates with the combustion ch...

Embodiment 2

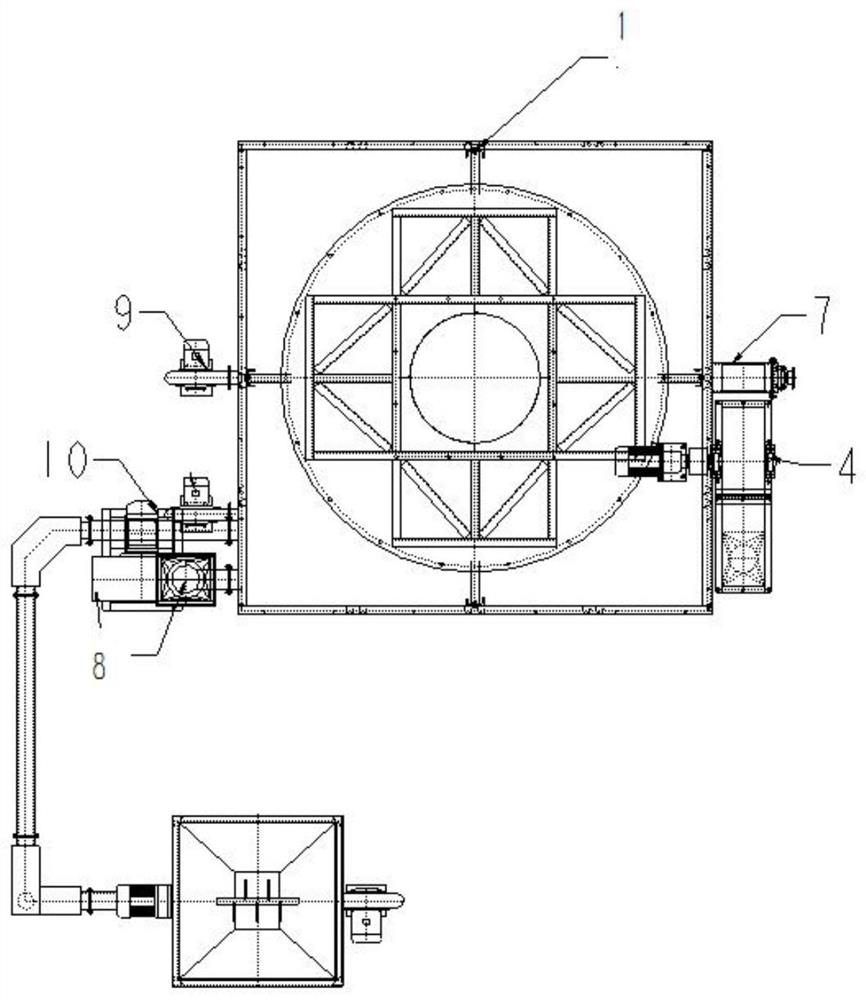

[0042] see Figure 4-Figure 12The present invention provides a technical solution: the inner cavity of the furnace body 1 is made of 6-inch white bricks and T20 refractory bricks, with an inner cavity of φ1860±2mm, and the cross-section of the inner cavity of the furnace body 1 is upwardly inclined by 19°, And the combustion chamber 1 is divided into six sections, of which the first section is the ignition chamber 101, the second to sixth sections are respectively: the second section of the combustion chamber 102, the third section of the combustion chamber 103, the fourth section of the combustion chamber 104, and the fifth section of the combustion chamber 104. Section combustion chamber 105, sixth section combustion chamber 106, the upper end of the second section combustion chamber 102 is provided with a flameout pipe, the flameout pipe is communicated with the flameout fan 10, and the lower end of the second section combustion chamber 102 is provided with an inspection por...

Embodiment 4

[0045] see Figure 11 The present invention provides a technical solution: the feed port 301 of the feed lifting device 3 is set below the combustion chamber 105 of the fifth section, and the feed port 301 and the tangent to the cross section of the furnace cavity are at an elevation angle of 28°. Under the action of the combustion-supporting fan 8, a negative pressure area will be formed at the feed port 301, and the biomass will be sucked in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com