Methods To Control Organic Contaminants In Fibers

a technology of organic contaminants and fibers, applied in the field of papermaking processes, can solve the problems of inefficiency, maintenance problems and production inefficiencies, need to bleach fibers, and difficulty in controlling or removing them,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0102]In the following tested samples, contaminant control in recycled paper was examined. In the Examples, several versions of the methods of the present application were tested and compared with comparative treatments. In the Examples, experimental testing was done at a papermill, wherein heavyweight coated publication paper was made using post-consumer waste paper pulp. The following treatments were made separately to pulp that was present in a pulper as follows:

TABLE 1Avg. Streak% DefectiveRunTreatmentOccurrenceRolls1Control (untreated)Not measured, 6%but streaks present2Diatomaceous earth0.321.2%3Enzyme with detackifier0.280.7%4Diatomaceous earth with0.17 0%enzyme and detackifier

[0103]The diatomaceous earth (DE) was Celite 500 diatomaceous earth from Celite Corporation, and was used in the amount of 10 pounds per dry ton of fiber in Run 2 and Run 4. The detackifier was a methylcellulose detackifier, which was Methocel F50 from Dow Chemical Co., and used in the amount of 0.13 po...

example 2

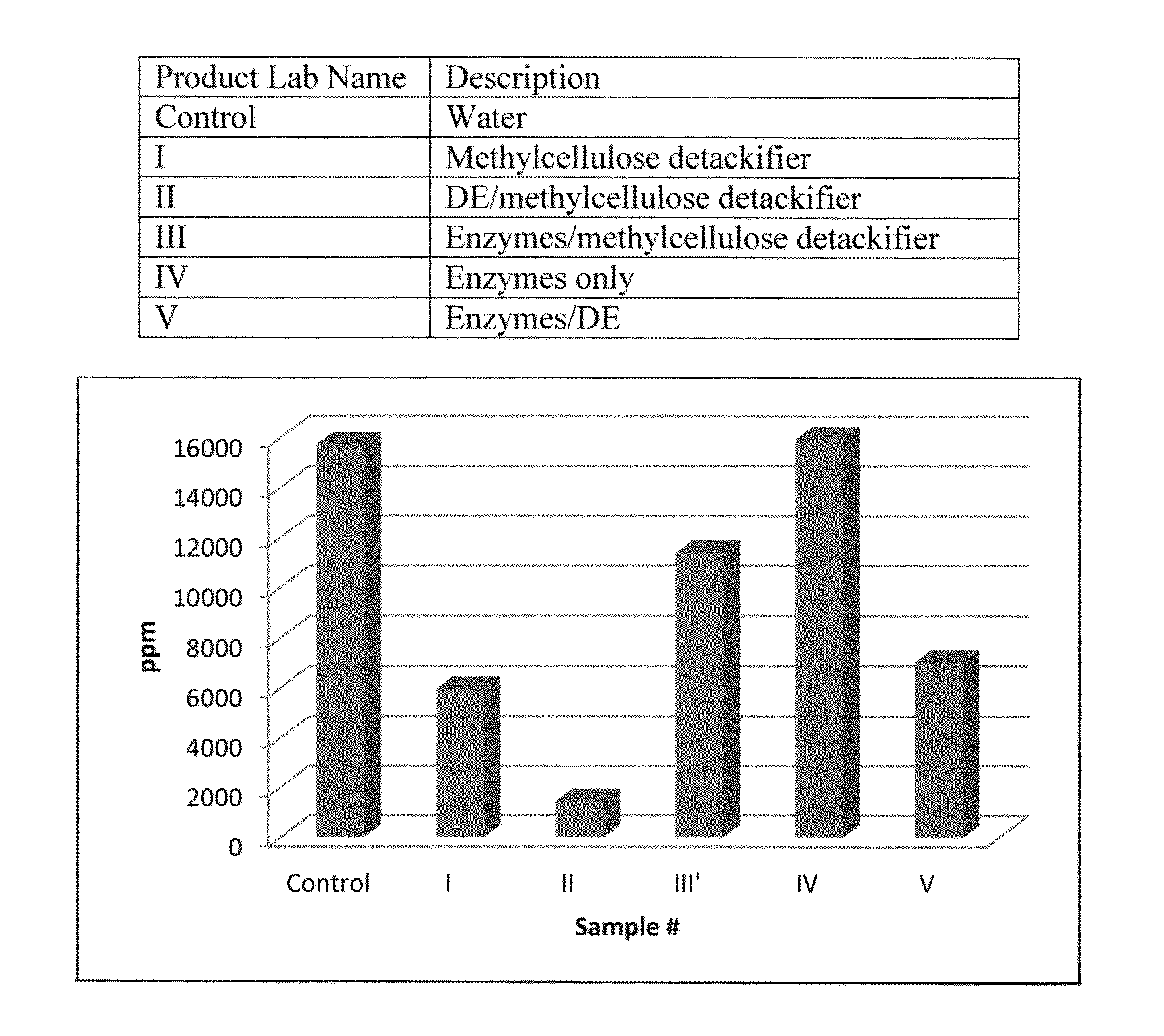

[0105]In the following tested samples, contaminant control in recycled paper was examined for compositions containing fibers and water and the below listed treatments.

TreatmentsDescriptionControlNo treatmentIMethylcellulose detackifierIIDE / methylcellulose detackifierIIIEnzymes / methylcellulose detackifierIVEnzymes onlyVEnzymes / DE

[0106]DE was Celite 500 diatomaceous earth from Celite Corporation, and was used in the amount of 10 pounds per dry ton of fiber. The methylcellulose detackifier was Methocel F50 from Dow Chemical Co., and used in the amount of 0.20 pound per dry ton of fiber. The enzyme(s) was NS51032 and from Novozymes, and used in the amount of 0.06 pound per dry ton of fiber.

[0107]In each of the following tested samples, a machine chest stock resulting from used hot melt glued, single wall corrugated containers was obtained from a mill and had approximately 3 to about 5% by weight consistency of fibers or solids. This stock was then diluted to a 1% by weight consistency t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com