CMP PAD Conditioning Tool

a technology of conditioning tool and pad, which is applied in the direction of manufacturing tools, grinding devices, abrasive surface conditioning devices, etc., can solve the problems of limiting the control of the conditioning process, releasing abrasive particles or other contaminants onto the wafer, and affecting the quality of the wafer, so as to prevent the loss of abrasive particles and high strength bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0062]An approximately cylindrical SiC-diamond composite was prepared according to the following procedure. A mixture comprising about 90% diamond by weight, about 9.5% Si powder by weight, and about 0.5% Si3N4 by weight was prepared. The diamond powder included 4 parts of a diamond powder with a particle size of about 20 microns and 1 part of a diamond powder with an average particle size of about 5 microns. The Si powder had an average particle size of less than about 10 microns, and the Si3N4 powder had a particle size of about 1 micron.

[0063]The powder mixture was subsequently loaded into a pressure cell and placed in contact with a body of silicon. This material was then subject to HPHT at a pressure of up to about 30 kBar at about 1600° C. After 30 minutes, the temperature and pressure were gradually reduced to ambient conditions and an approximately cylindrical SiC-diamond composite sample was recovered from the pressure cell.

[0064]The resulting diamond composite comprised ap...

example 2

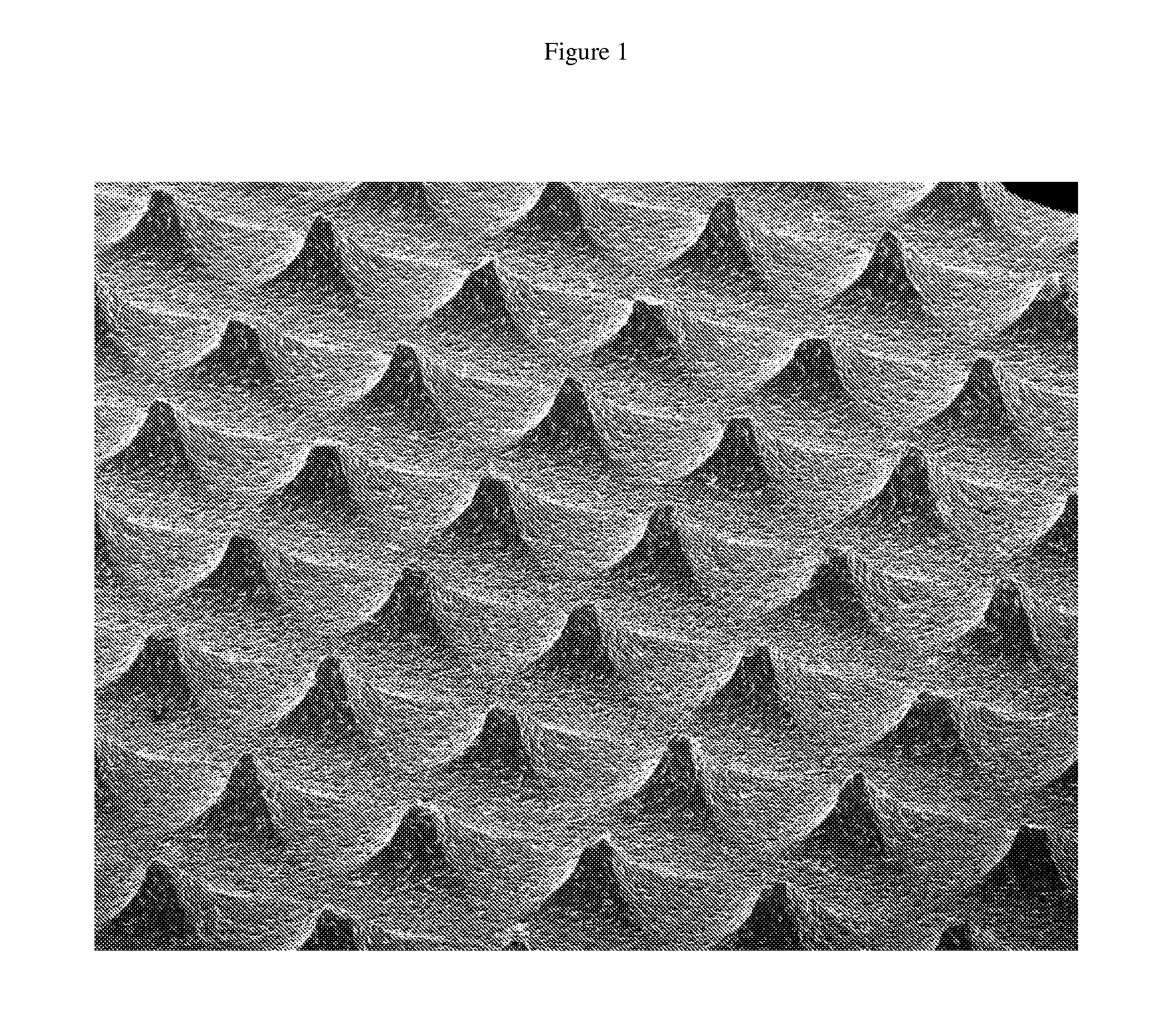

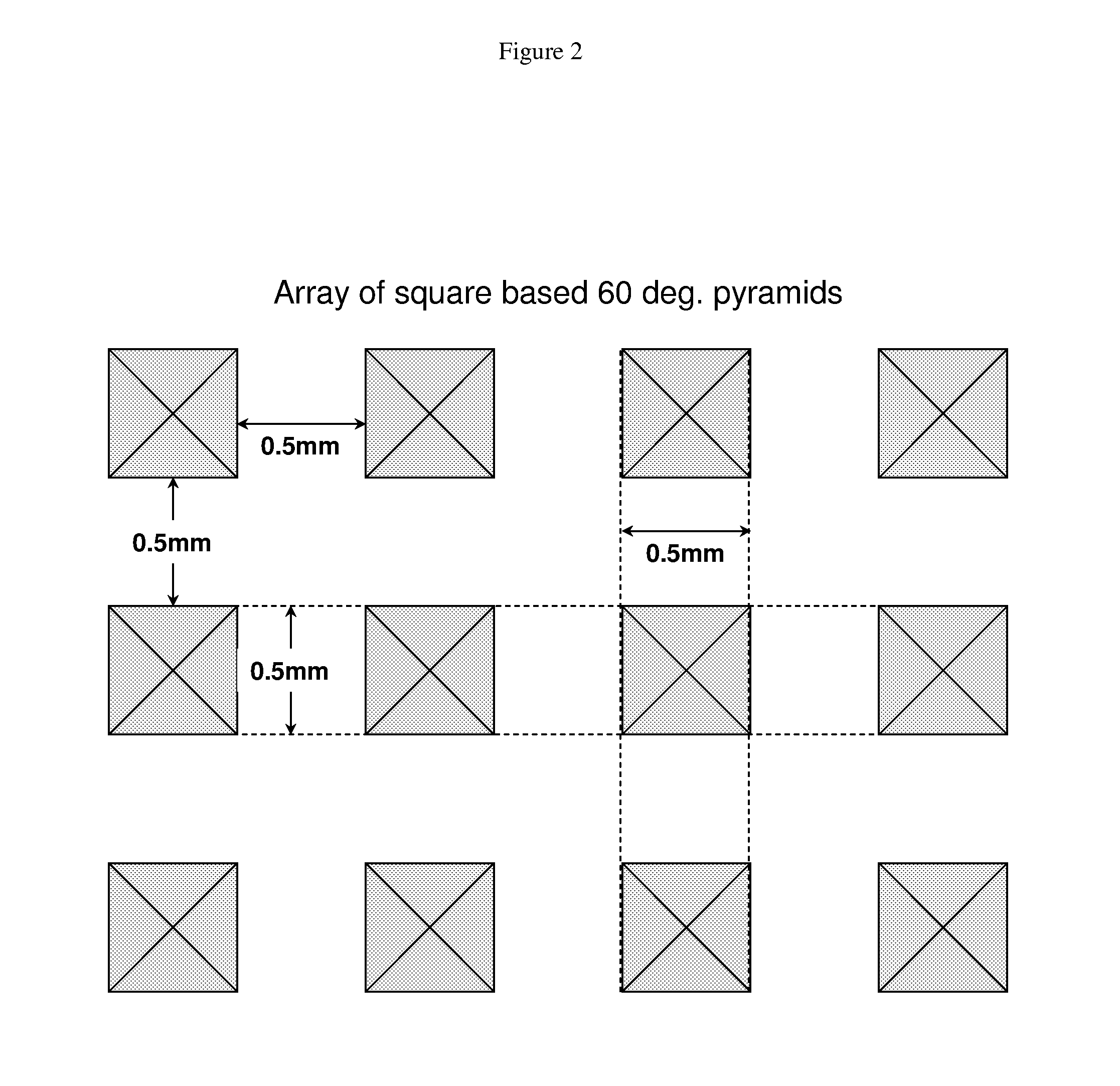

[0065]A CMP pad conditioner having the surface pattern shown in FIG. 2 was prepared by the following process. All machining was performed on a Fanuc Robocut alpha-oc wire EDM machine. In the wire EDM machine, a 0.008″ diameter wire was held in a vertical orientation, and a cylinder of SiC-diamond composite prepared according to Example 1 was mounted with the cylinder's axis in a horizontal orientation. A first cut was made perpendicular to the cylinder's axis, to expose a fresh surface of SiC-diamond composite.

[0066]A series of second cuts was then made into and across this fresh surface. This series of cuts consisted of a cut angled at 30 degrees, 0.5 mm into the surface of the sample; a cut 0.2 mm in length parallel to the surface of the sample at the 0.5 mm depth; and a subsequent cut at an angle of −30 degrees out of the surface. This series of cuts resulted in a trough in the surface of the SiC-diamond composite. A graphical representation of this cutting pattern is shown in FI...

example 3

[0068]A CMP pad conditioner having the surface pattern shown in FIG. 6 was prepared by the same process as in Example 2, except for the following differences.

[0069]A series of second cuts was then made into and across this fresh surface. This series of cuts consisted of a cut angled at −15 degrees, 0.5 mm into the surface of the sample; a cut 0.18 mm in length parallel to the surface of the sample at the 0.5 mm depth; and a subsequent cut at an angle of 15 degrees out of the surface. This series of cuts resulted in a trough in the surface of the SiC-diamond composite.

[0070]This series of cuts was repeated across the surface of the cylinder such that a series of parallel troughs were formed. Next, the cylinder was rotated by 120 degrees about its axis and a series of third cuts, identical to the series of second cuts, was made. Next, the cylinder was rotated again by 120 degrees and a series of fourth cuts, identical to the series of second and third cuts, leaving a matrix of triangu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com