Method for precisely controlled masked anodization

a technology of masking and anodization, which is applied in the direction of coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problem of self-limitation of the anodization process, and achieve the effect of improving and cost-efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0103]By way of illustration, preferred embodiments not being limited thereto, a number of further particular examples are discussed below, illustrating features and advantages of preferred embodiments.

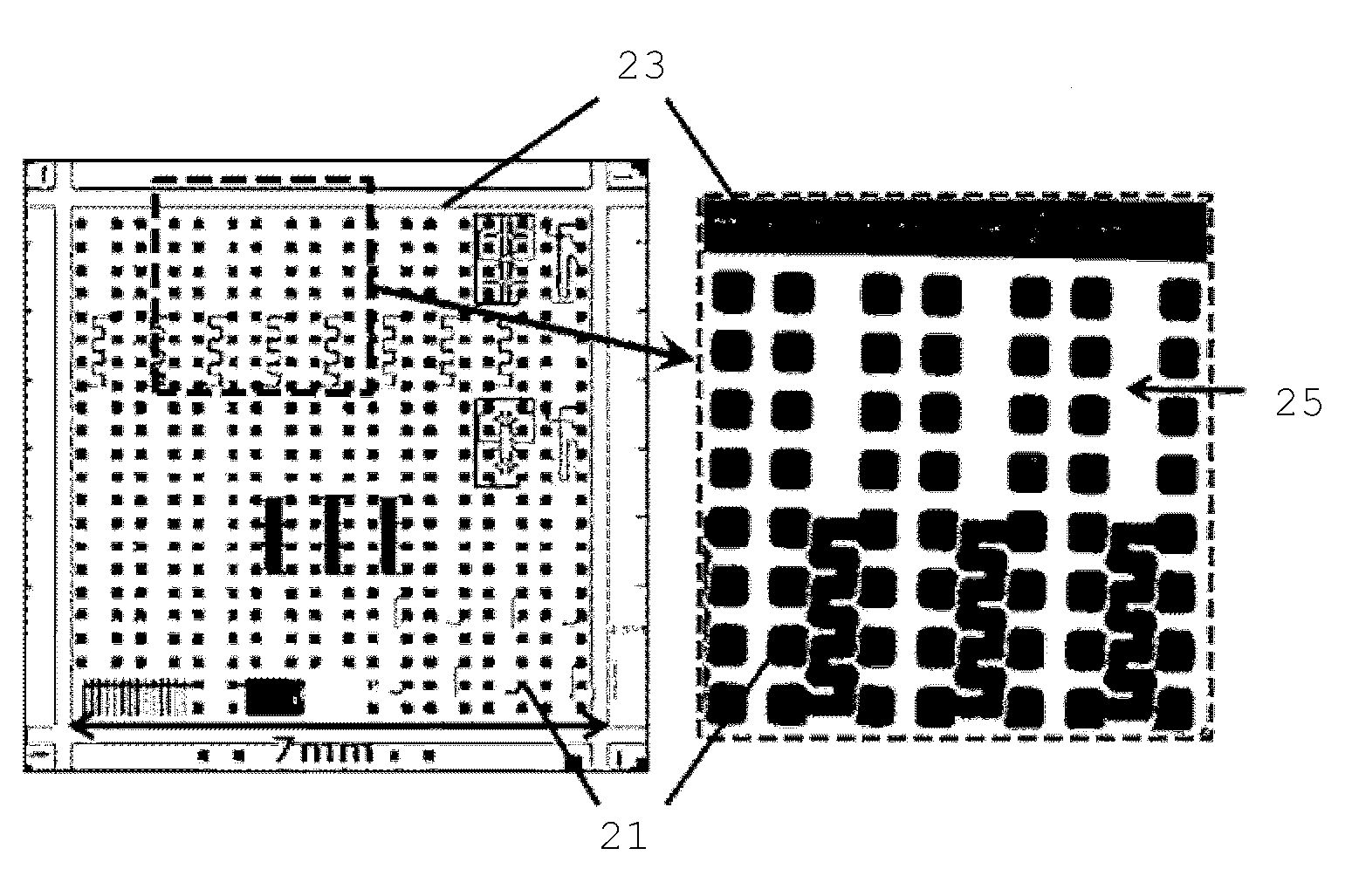

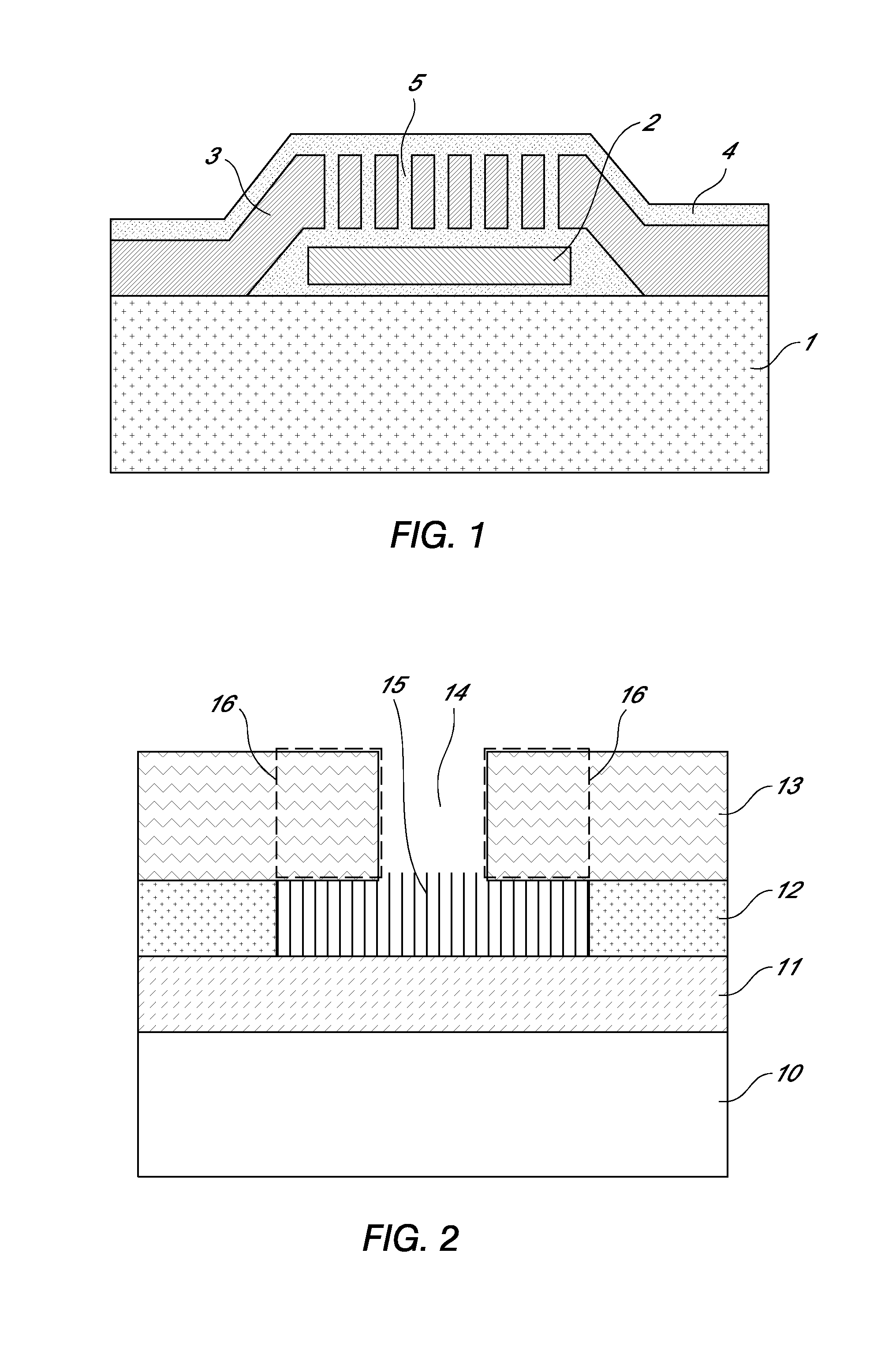

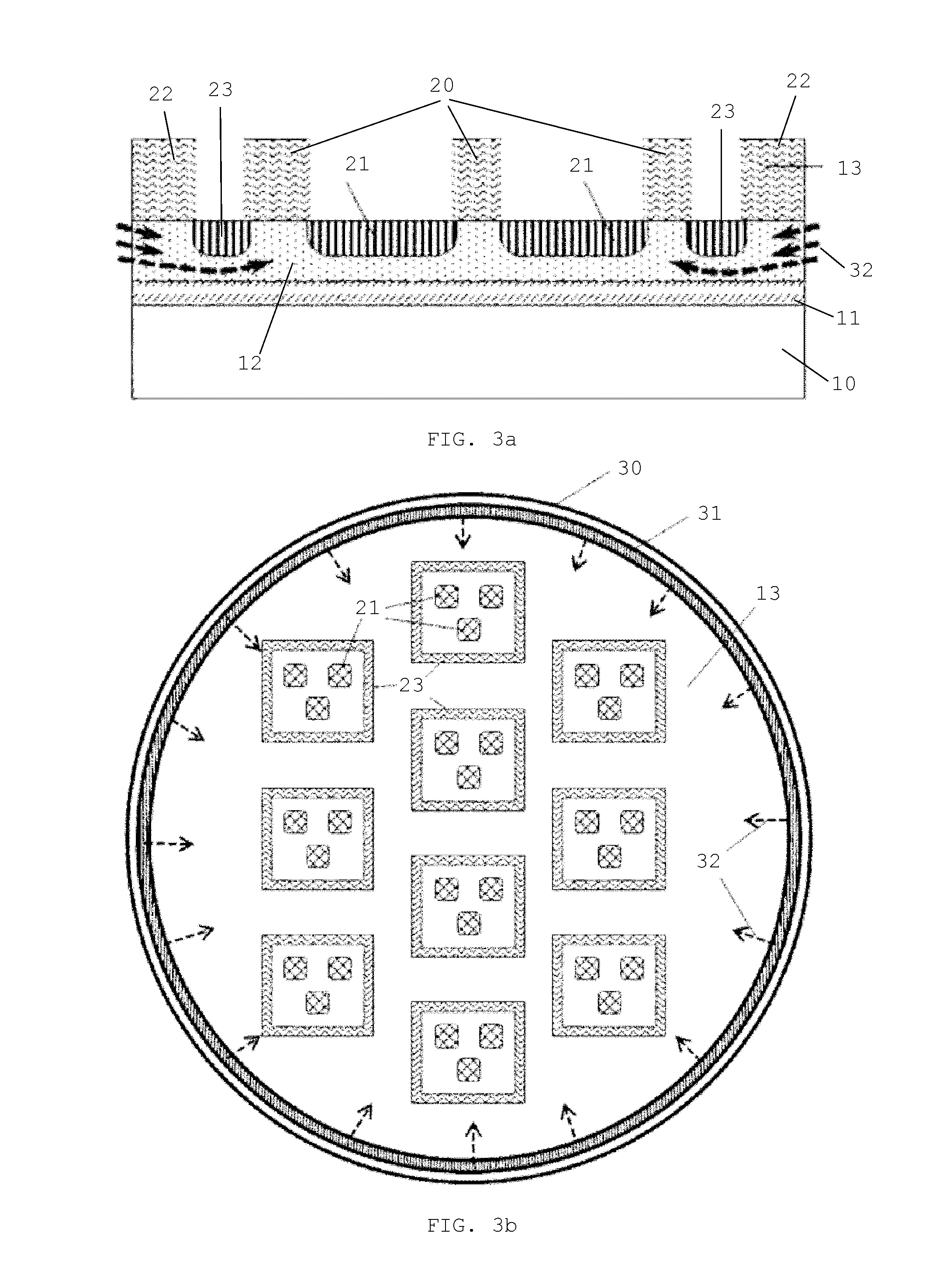

[0104]In a first particular example, anodization of a 1 μm-thick Al layer (deposited by sputtering on top of a silicon oxide layer on 200 mm Si wafer) has been performed using a photoresist mask not including the border line structure resulting in a large unwanted extension of the anodization region width from 160 μm up to 800 μm as shown in FIG. 2. The anodization process is performed in a Teflon-based chamber housing a sulfuric acid-based electrolyte. The anodization temperature and voltage used here are within the range of 20-30° C. and 10-20V respectively. By performing the same anodization process of an Al layer using a photoresist mask defining a border line 23 (ring) surrounding a plurality of other structures 21 as shown in FIG. 6, the anodization region width has been well co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com