Aerodynamic Garment With Applied Surface Roughness And Method Of Manufacture

a technology of surface roughness and aerodynamic garment, applied in the field of aerodynamic garment, can solve the problems of increasing production costs, limited success of engineers and designers in quantifying and selecting the optimal surface texture of aerodynamic garment for a particular sporting event, and limiting the use of commercial athletic garment fabrics without much guidance for determining, so as to reduce the weight and/or bulk of other types, reduce the effect of air resistance at the seams, and add elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

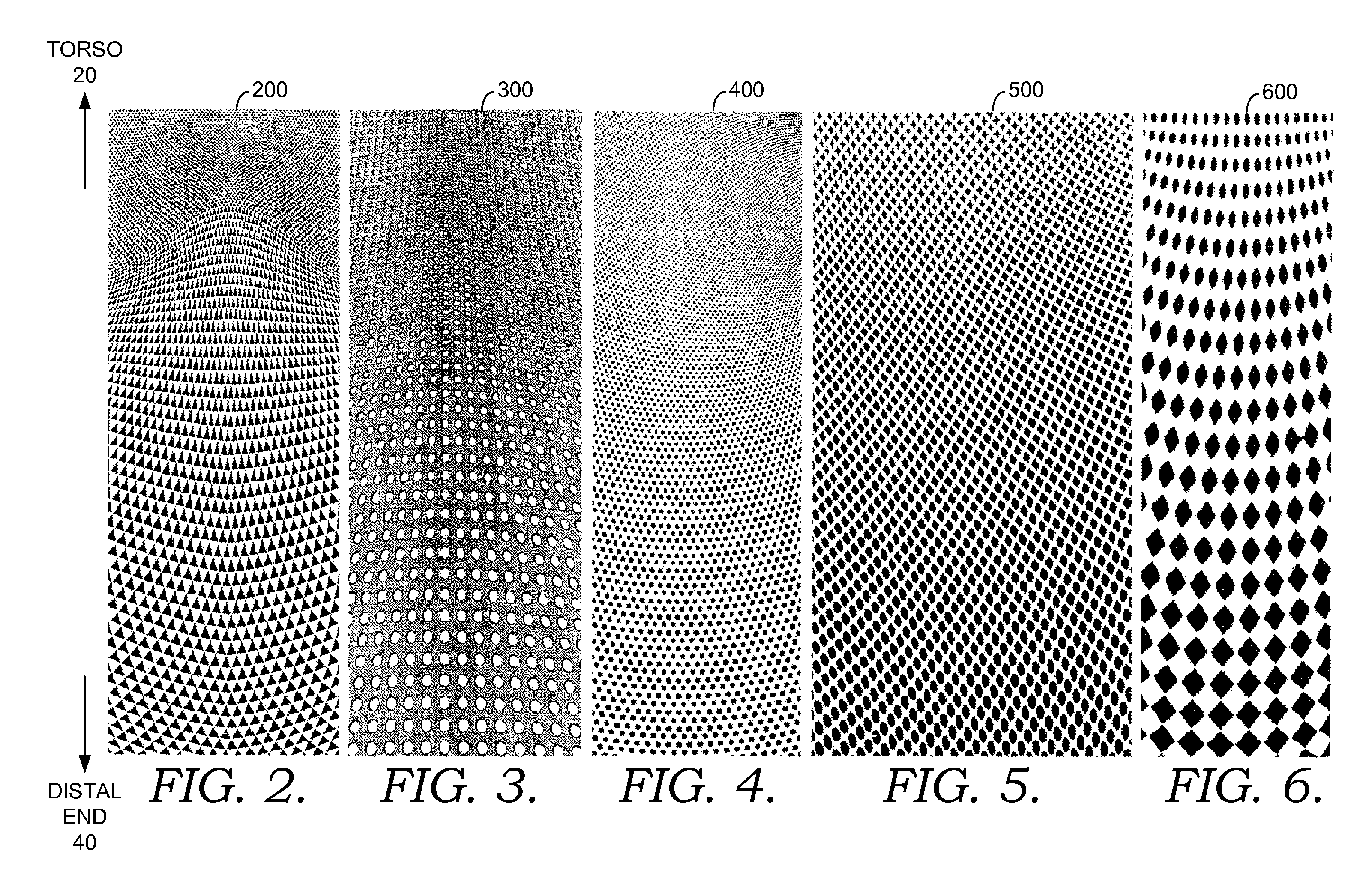

[0028]Referring to FIG. 1, an exemplary embodiment 100 of an athletic garment 110 with sections of surface roughness 112 applied thereto is shown. Athletic garment 110 is a suit having a torso portion 120, leg portions 122 and arm portions 124. Each portion may be sized and shaped to snugly cover their respective portions of an athlete 130 as shown. Each of the portions 120, 122, 124 may be formed of with a fabric offering optimal stretching, comfort, and / or performance effects for the region of the body over which it covers. Sections of surface roughness 112 may be applied to the underlying fabric of the suit to further optimize aerodynamic properties of the suit, such as the drag reducing properties of the suit. As such, the respective portions 120, 122, 124 of the garment 110 may be formed from a sheet of material that is not necessarily selected for its optimal aerodynamic properties. Rather, those properties may be optimized by the application of the surface roughness 112 at op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com