Apparatus for collecting oil escaped from an underwater blowout

a technology for escaping oil and apparatus, which is applied in the direction of underwater drilling, drilling machines and methods, and borehole/well accessories, etc. it can solve the problems of leaking oil in the steel casing and the underlying rock formation, leaking oil, and blowout, etc., and achieves the effect of facilitating pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

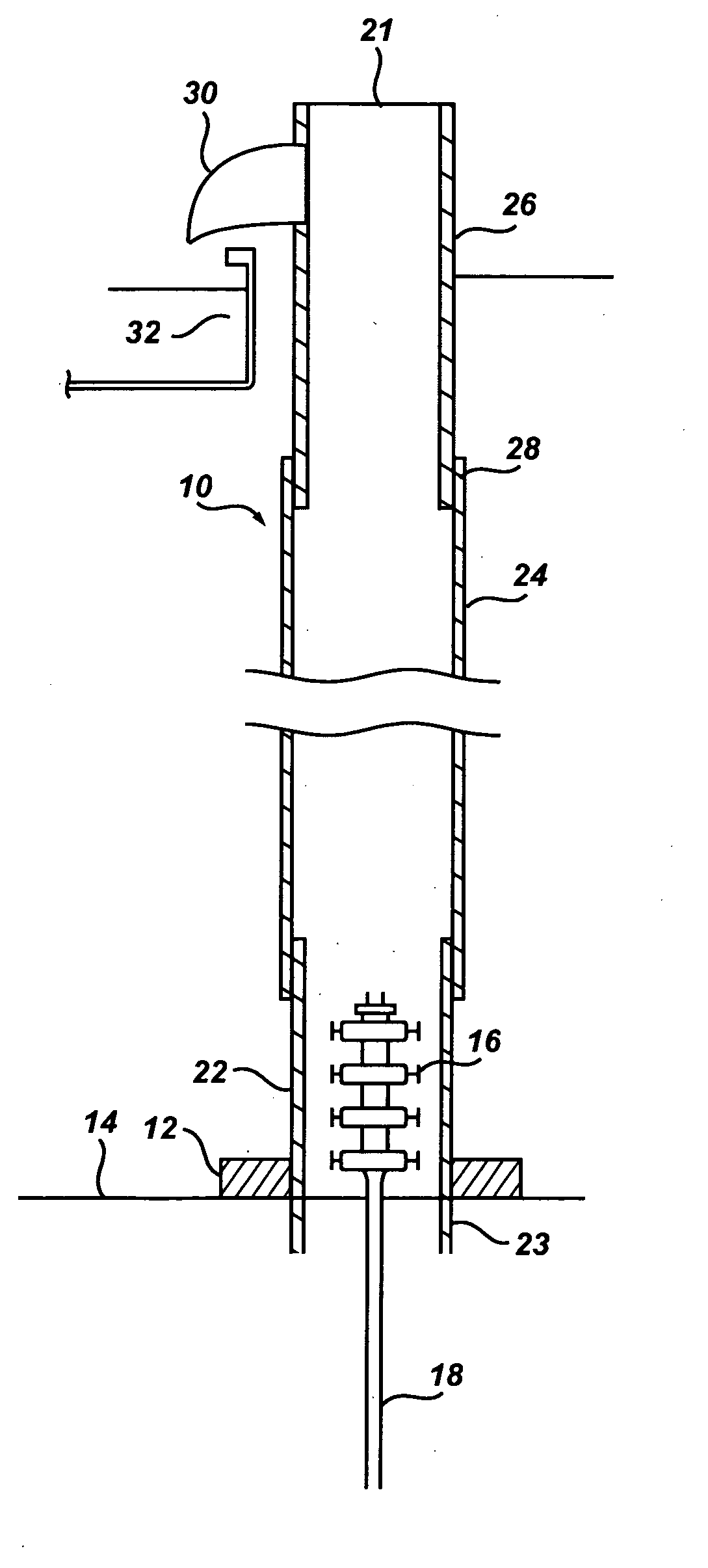

[0017]As apparent from FIGS. 1 and 2, the apparatus 10 comprises a ring-shaped base 12 configured to rest on a sea bottom 14 in a surrounding relationship to a wellhead 16. The base has a central opening configured to receive a tubular channeling member 20 therethrough, as will be explained in more detail hereinafter.

[0018]The wellhead 16 can be in the form of a conventional subsea Christmas tree, with a plurality of valves for regulating a flow of liquids to and from a drill pipe or production pipe 18. Conventionally, the drill / production pipe 18 penetrates the formation to reach a producing zone (not shown), while the Christmas tree 16 is mounted in the upper part of the drill / production pipe 18.

[0019]The base 12 is preferably formed as a weighted non-buoyant member that resists displacement by the water current. If one aspect of the invention, the base 12 is a ring-shaped hollow body filled with concrete to assure an appropriate seal between a bottom surface 15 of the base 12 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com