Aluminium oxide forming nickel based alloy

a nickel-based alloy and alloy technology, applied in the direction of manufacturing tools, cores/yokes, magnetic bodies, etc., can solve the problems of alloy hard and brittleness, and low growth rate of aluminum oxide forming nickel-based alloys, etc., to achieve good hot workability, excellent oxidation resistance, good creep strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

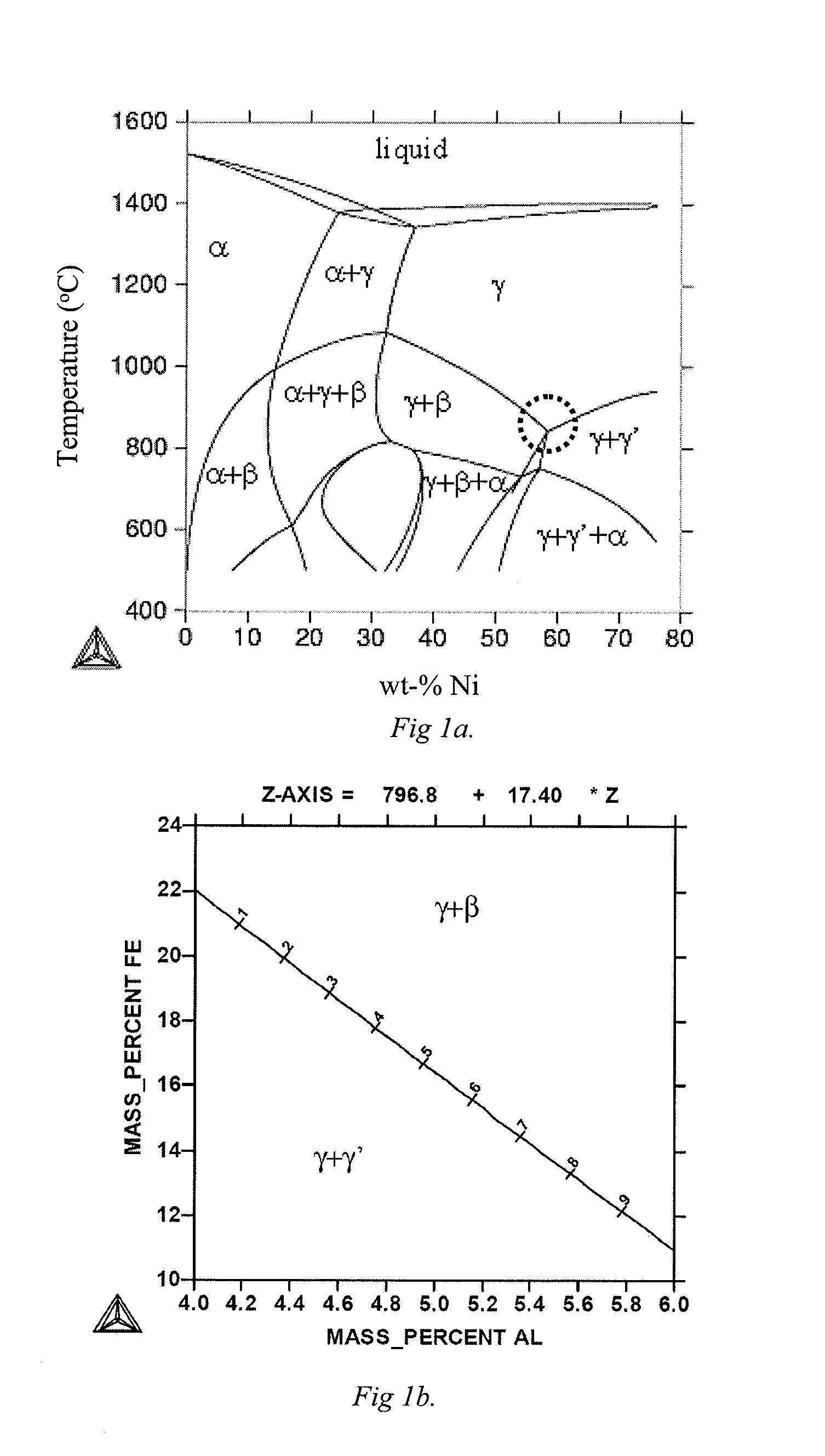

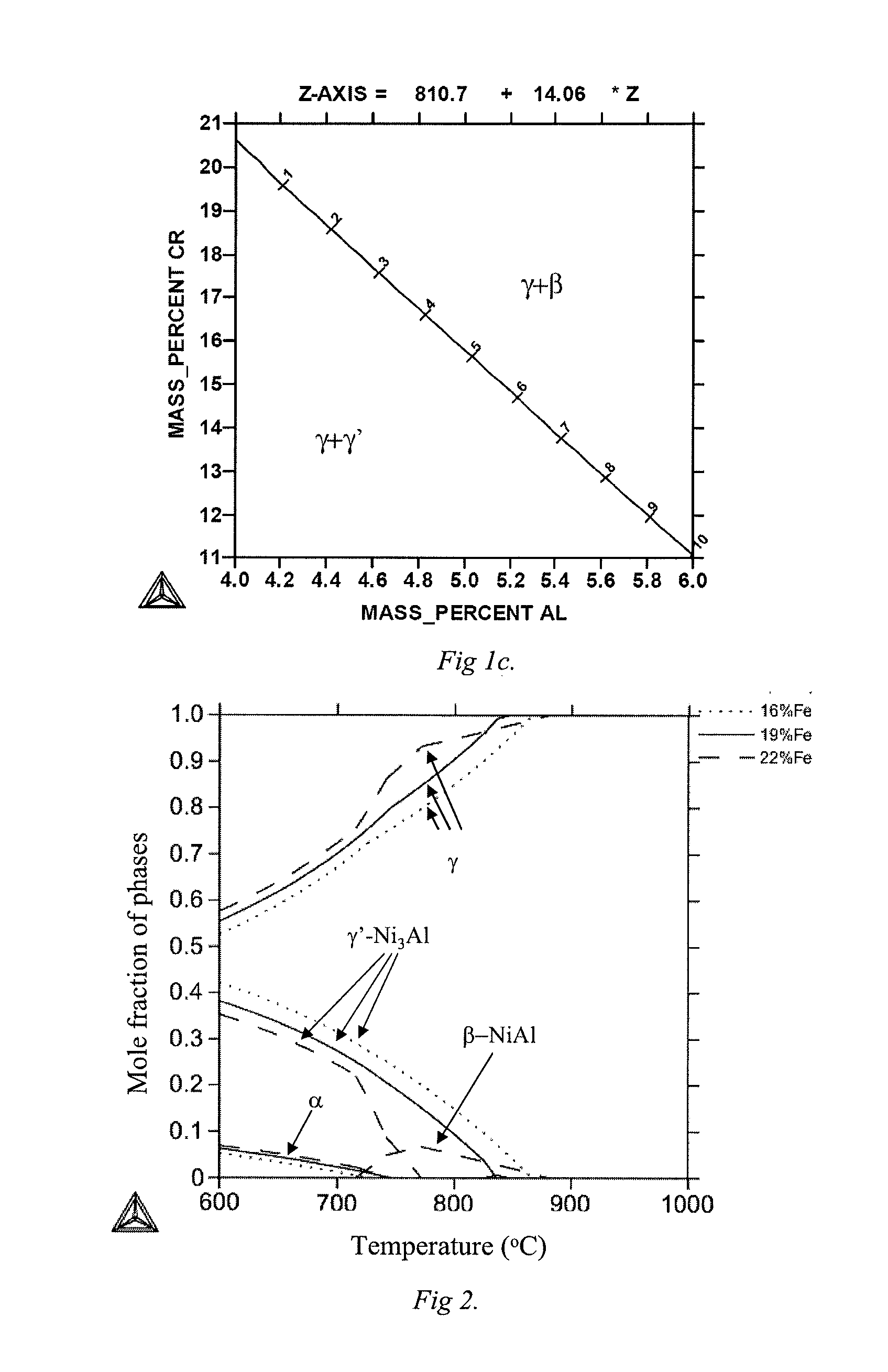

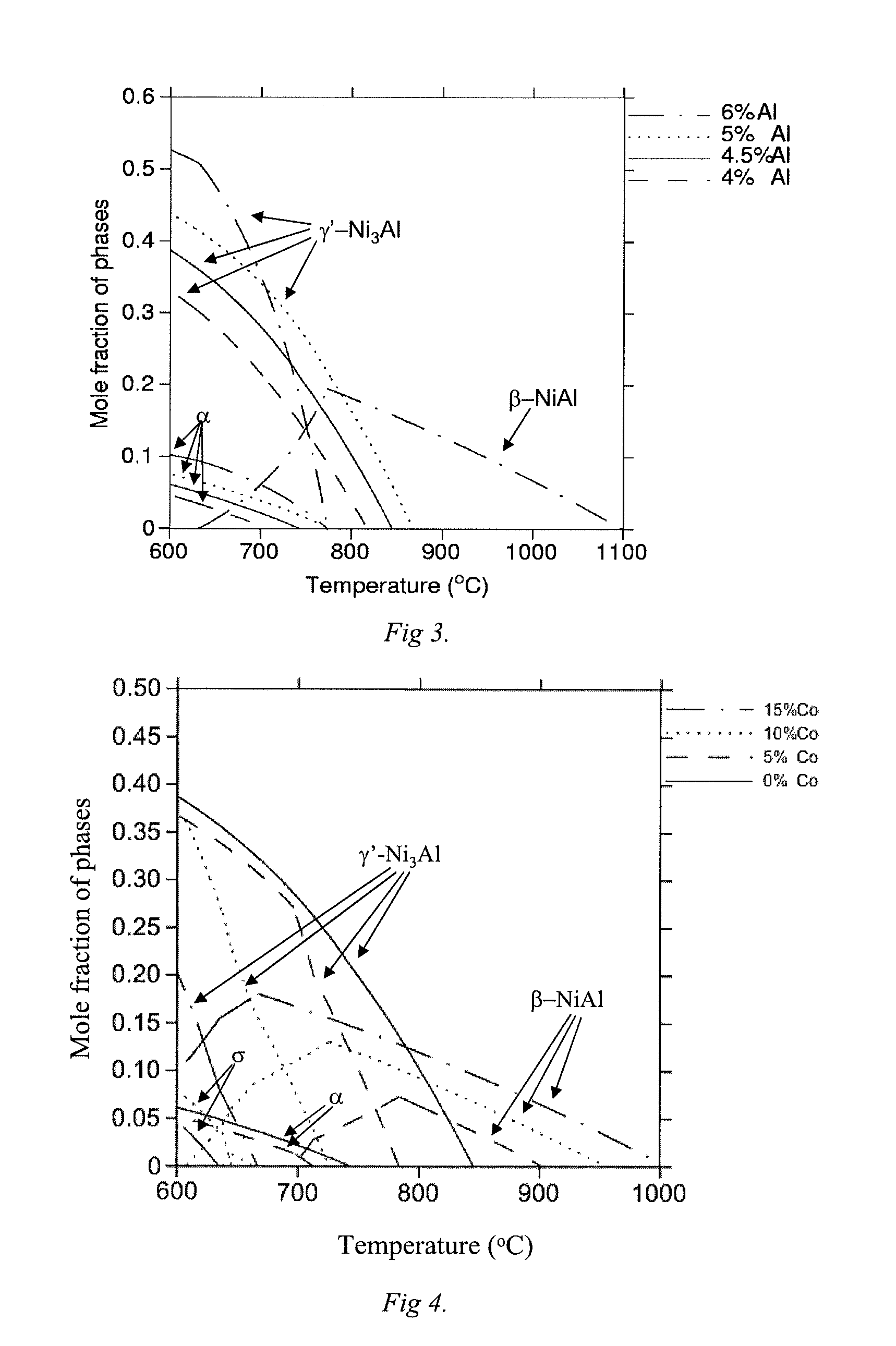

[0034]As mentioned above, nickel based alloys alloyed with aluminium are generally considered difficult to hot-work. An important factor is that there is only a limited temperature window between melting of the alloy and precipitation of unwanted intermetallic phases, such as nickel aluminides. The alloying elements Al and Cr are both beneficial for the oxidation resistance but makes a nickel based alloy difficult to work since they increase the stability of nickel aluminides and therefore reduces the temperature window for hot-working of the alloy. The hot workability of the alloy is a very important factor for enabling that products thereof can be readily and economically produced. It has been found that the alloy in accordance with the present invention has an increased temperature window for hot-working as a result of its composition which gives the alloy a good hot-workability.

[0035]The present invention is based on the discovery that relatively high addition of Fe to a nickel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com