Surfactant Composition for Agricultural Chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

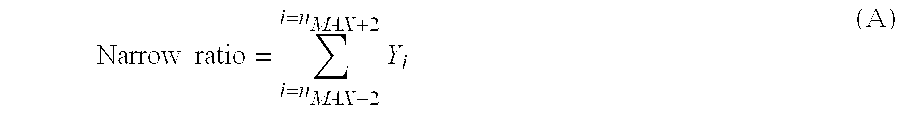

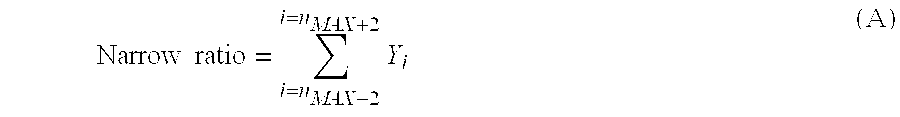

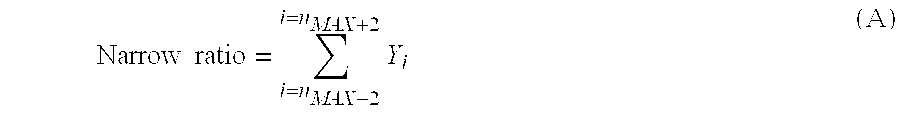

Image

Examples

example 1

[0109]An alumina-magnesia complex oxide (Kyowado 300, manufactured by Kyowa Chemical Industry Co., Ltd.) expressed by the chemical formula 2.5MgO.Al2O3.nH2O was baked at 750° C. for 3 hours under nitrogen gas streams to thereby obtain a baked alumina-magnesia complex oxide (Al / Mg molar ratio=0.44 / 0.56) catalyst. Into a 4-L autoclave, 1,073 g of methyl oleate (fatty acid methyl ester derived from C18 fractions derived from palm oil, product name: PASTELL M182, manufacturer: Lion Corporation, iodine value: 91), 5 g of the obtained catalyst, and 0.58 g of 40% KOH as a modifying agent for the catalyst were added, and the inner atmosphere of the autoclave was replaced with nitrogen gas twice.

[0110]Thereafter, the temperature was increased to 180° C., the pressure inside the reaction vessel was returned to normal pressure by nitrogen, and then 628 g of PO (3 moles relative to 1 mole of methyl oleate) was gradually introduced to the vessel. The pressure just after the completion of the int...

example 2

[0112]A compound 1B was obtained by a block addition reaction of PO and EO in the same manner as in Example 1, provided that the amount of PO added was changed to 565 g (2.7 moles relative to 1 mole of methyl oleate), and the obtained intermediate product 1B was subjected to vacuum distillation by reducing the pressure to 10 Torr or lower, while increasing the temperature stepwise from 175° C. to 200° C. stepwise, so as to remove unreacted methyl ester contained in the intermediate product 1B. The intermediate product 1B contained 0.8% by mass of unreacted fatty acid methyl ester. The compound 1B obtained by further subjecting to an addition reaction of EO contained 0.3% by mass of unreacted fatty acid methyl ester. The results of measurements and evaluation are shown in Tables 1 and 2.

example 3

[0113]A compound 1C was obtained by performed a block addition reaction of PO and EO in the same manner as in Example 2, provided that 40% KOH was not added as the modifying agent for the catalyst. The intermediate product 1C after the vacuum distillation contained 1.8% by mass of fatty acid methyl ester. The compound 1C obtained by further subjecting to an addition reaction of EO contained 1.6% by mass of unreacted fatty acid methyl ester. The results of measurements and evaluation are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com