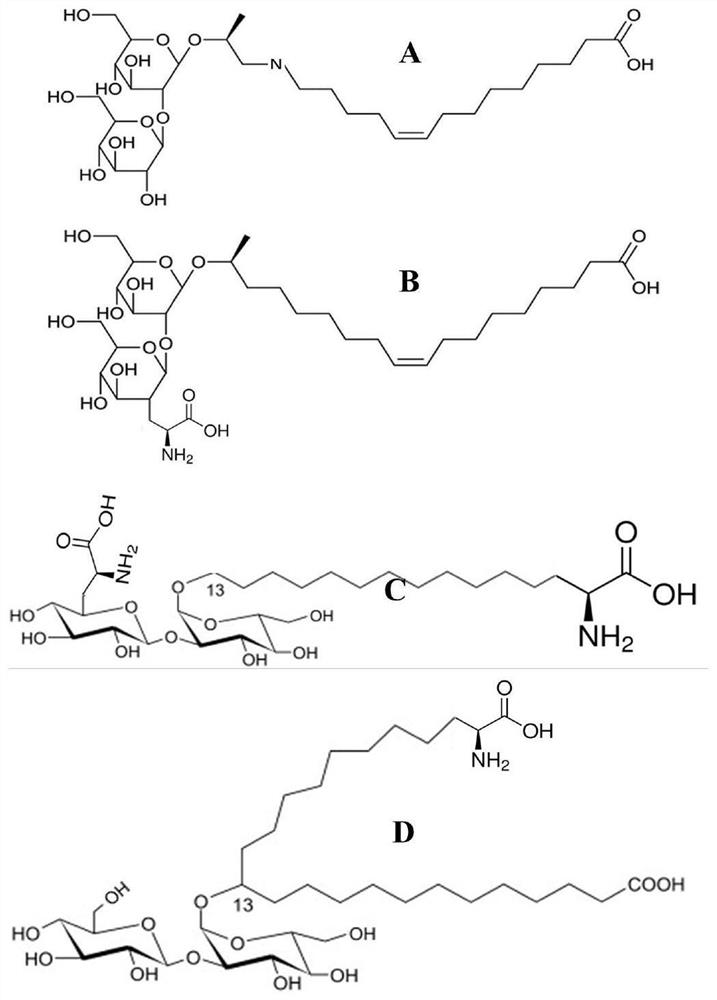

Amphoteric glycolipid biosurfactant and preparation method thereof

A bio-surface, amphoteric glycolipid technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve problems such as the decline of the overall effect, and achieve the effects of low cost, excellent surface and interface activity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation method of amphoteric glycolipid biosurfactant molecule is

[0058] 1. Bacteria: Amphoteric glycolipid biosurfactants need to be cultivated in sequence with three bacteria, Pseudomonas aeruginosa (ATCC 15442), Candida albicans (ATCC 10231), and Neurospora crassa (ATCC 18889).

[0059] 2. Medium: NaNO 3 : 0.4%, FeCl 2 : 0.002%, NaH 2 PO 4 : 0.25%, K 2 HPO 4 : 0.25%, MgSO 4 ·7H 2 O: 0.005%, KCl: 0.05%, Choline chloride: 0.05%, fatty amine: 0.5%, corn syrup: 0.05%, soybean oil 5%: 3.0%, glucose: 0.1%, yeast extract powder: 0.001%, initial pH 6 -7.

[0060] 3. Seed shake flask culture

[0061] The slant strains were cultured for 48 hours, and the three above-mentioned single-bacteria slants were respectively transferred to 1L Erlenmeyer flasks, in which 200mL of LB or YPD medium was filled in the Erlenmeyer flasks, and Pseudomonas and Candida were cultured at about 35°C. Candida was cultured at about 25°C, and Neurospora was cultured at about 30°C f...

Embodiment 2

[0085] Preparation method of amphoteric glycolipid biosurfactant molecule

[0086] 1. Bacteria: Amphoteric glycolipid biosurfactants need to be cultivated in sequence with three bacteria, Pseudomonas aeruginosa (ATCC 15442), Candida albicans (ATCC 10231), and Neurospora crassa (ATCC 18889).

[0087] 2. Medium: NaNO 3 : 1.4%, FeCl 2 : 0.005%, NaH 2 PO 4: 0.4%, K 2 HPO 4 : 0.4%, MgSO 4 ·7H 2 O: 0.01%, KCl: 0.09%, Choline chloride: 0.05%, fatty amine: 0.5%, corn syrup: 0.1%, soybean oil: 4.0%, glucose: 0.3%; yeast infusion powder: 0.004%, initial pH 6-7 .

[0088] 3. Seed shake flask culture

[0089] The slant strains were cultured for 36h-48h, and the three above-mentioned single-bacteria slants were transferred to 1L conical flasks respectively. The conical flasks were filled with 200mL of LB or YPD medium, and Pseudomonas was cultured at about 35°C. Candida candida was cultured at about 25°C, and Neurospora was cultured at about 30°C for 30 hours.

[0090] 4. Produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com