Housing Fastening Method

a fastening method and housing technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as deformation of fasteners, and achieve the effect of reducing the fastening for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

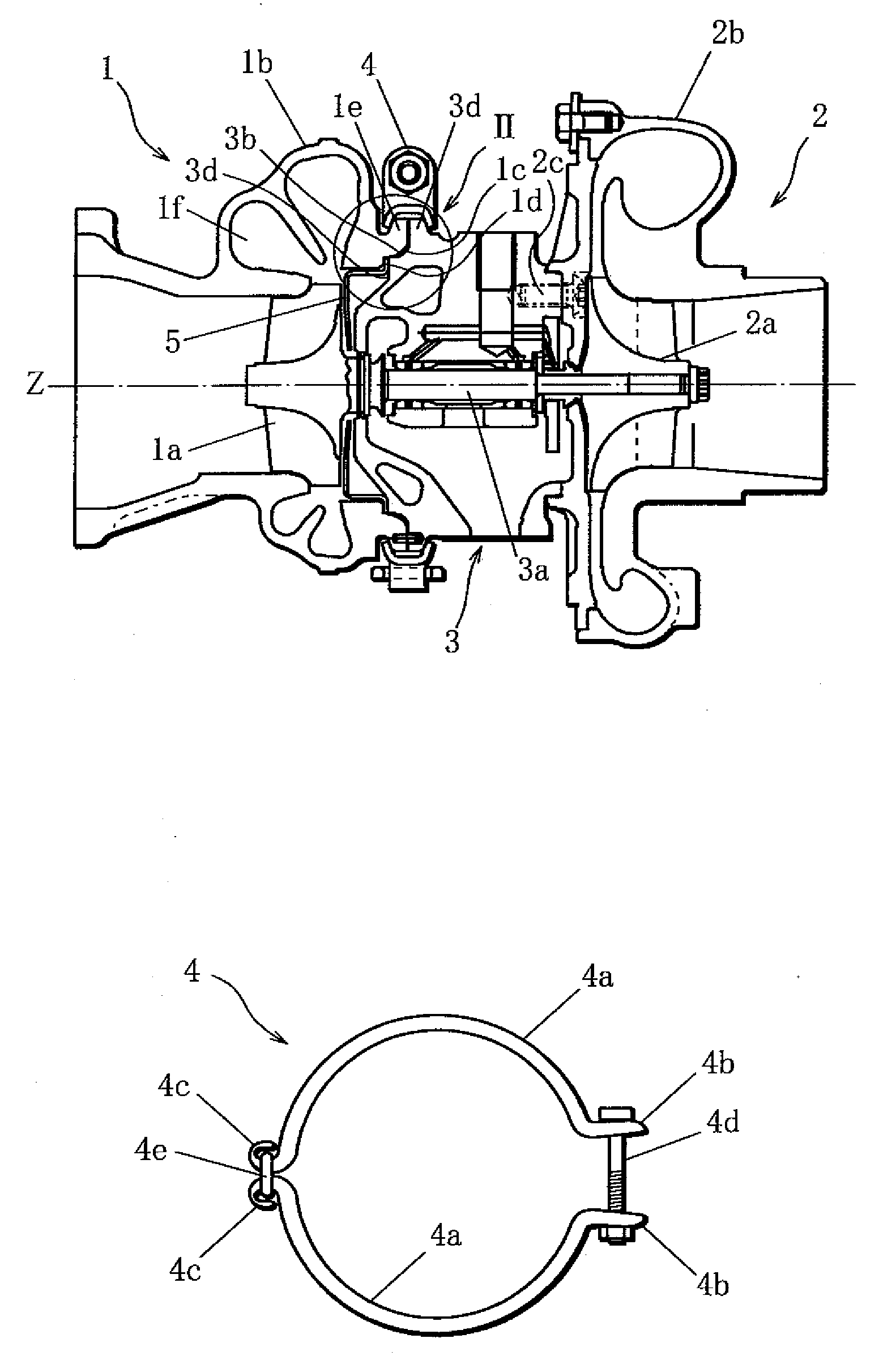

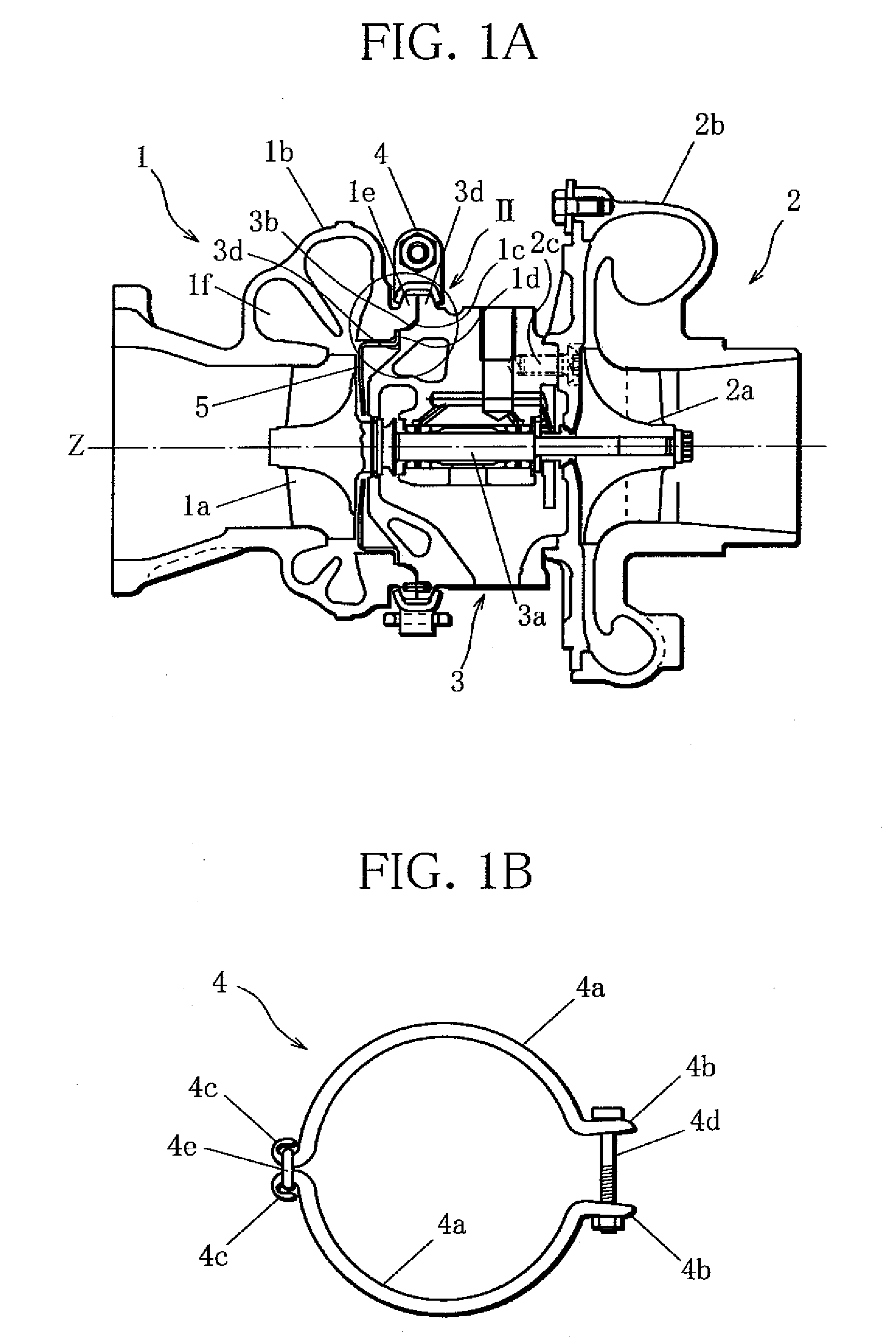

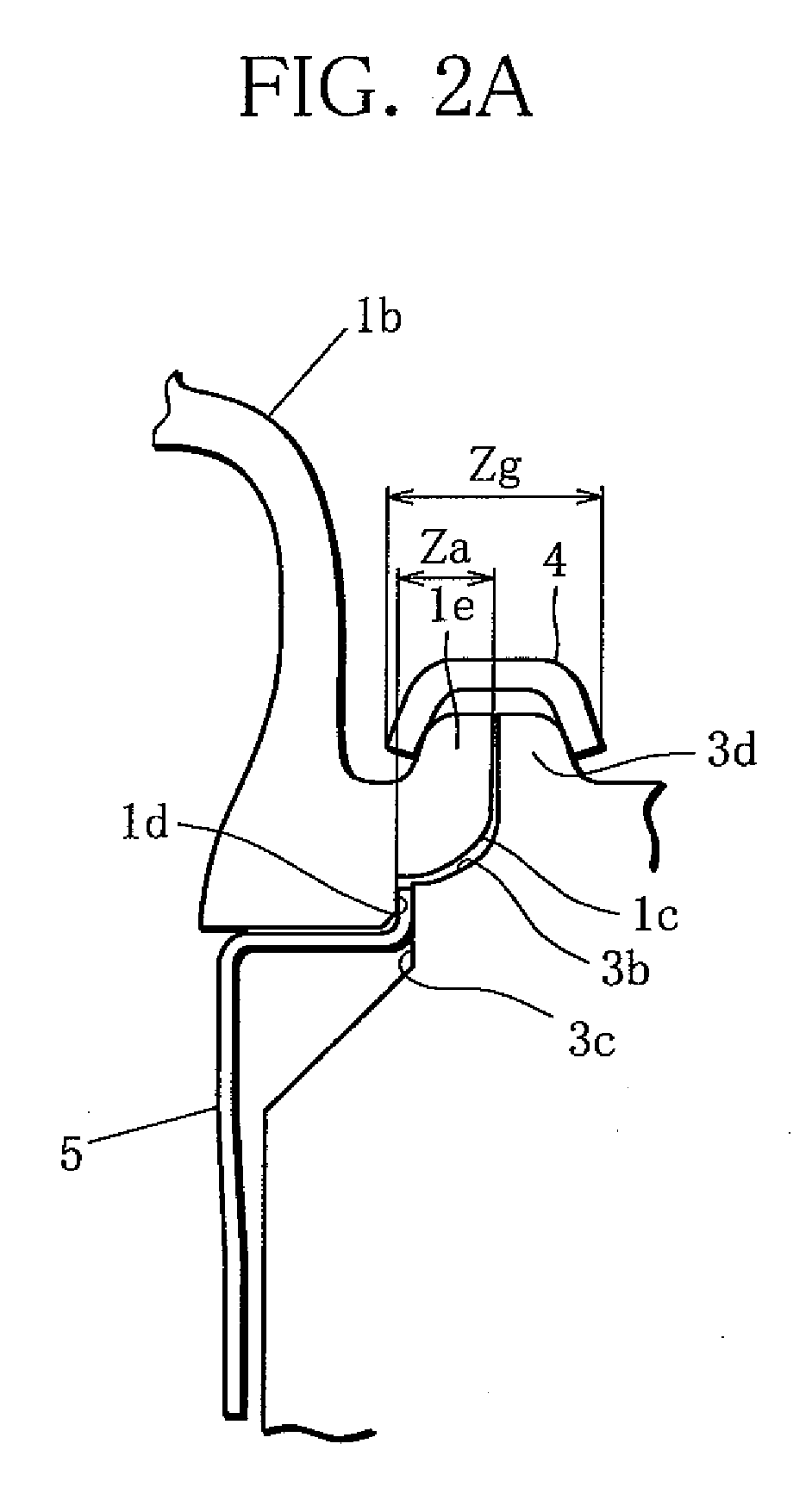

[0031]Referring to FIGS. 1A to 5B, embodiments of the present invention will be described below. FIG. 1A is a longitudinal cross-sectional view of a turbocharger according to the present invention, and FIG. 1B a front view of a G-coupling shown in FIG. 1A. FIG. 2A shows portion II of FIG. 1A on an enlarged scale, and FIG. 2B shows a portion corresponding to the portion shown in FIG. 2A in prior art.

[0032]The turbocharger according to the present invention shown in FIG. 1A comprises a turbine 1 including a bladed rotor la rotated by a fluid supplied thereto, a compressor 2 including an impeller 2a for drawing in air, connected with the bladed rotor 1a by a rotating shaft 3a, a turbine housing 1b constituting an outer shape of the turbine 1, and a bearing housing 3 rotatably supporting the rotating shaft 3a. The turbine housing 1a and the bearing housing 3 and the bearing housing 3 [sic] are assembled as follows: A projecting portion 3b of the bearing housing 3 is inserted in a recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com