Static solid state bioreactor and method for using same

a bioreactor and solid state technology, applied in the field of static solid state bioreactors and methods, can solve the problems of not being able to control the fermentation conditions within the ssf, the application of ssf to the production of fermentation products within the context of modern biotechnology is relatively limited, and the difficulty of substantial difficulties to achieve the effect of being convenient and cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]In the following description of the preferred embodiment, reference is made to the accompanying drawings that form a part hereof, and in which is shown by way of illustration a specific embodiment in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the present invention.

[0062]Consistent with its ordinary meaning as a renewable energy source, the term “biomass” is used herein to refer to living and recently dead biological material including carbohydrates, proteins and / or lipids that can be converted to fuel for industrial production. By way of non-limiting example, “biomass” can refer to plant matter, biodegradable solid waste such as dead trees and branches, yard clippings, recycled paper, recycled cardboard, and wood chips, plant or animal matter, and other biodegradable wastes.

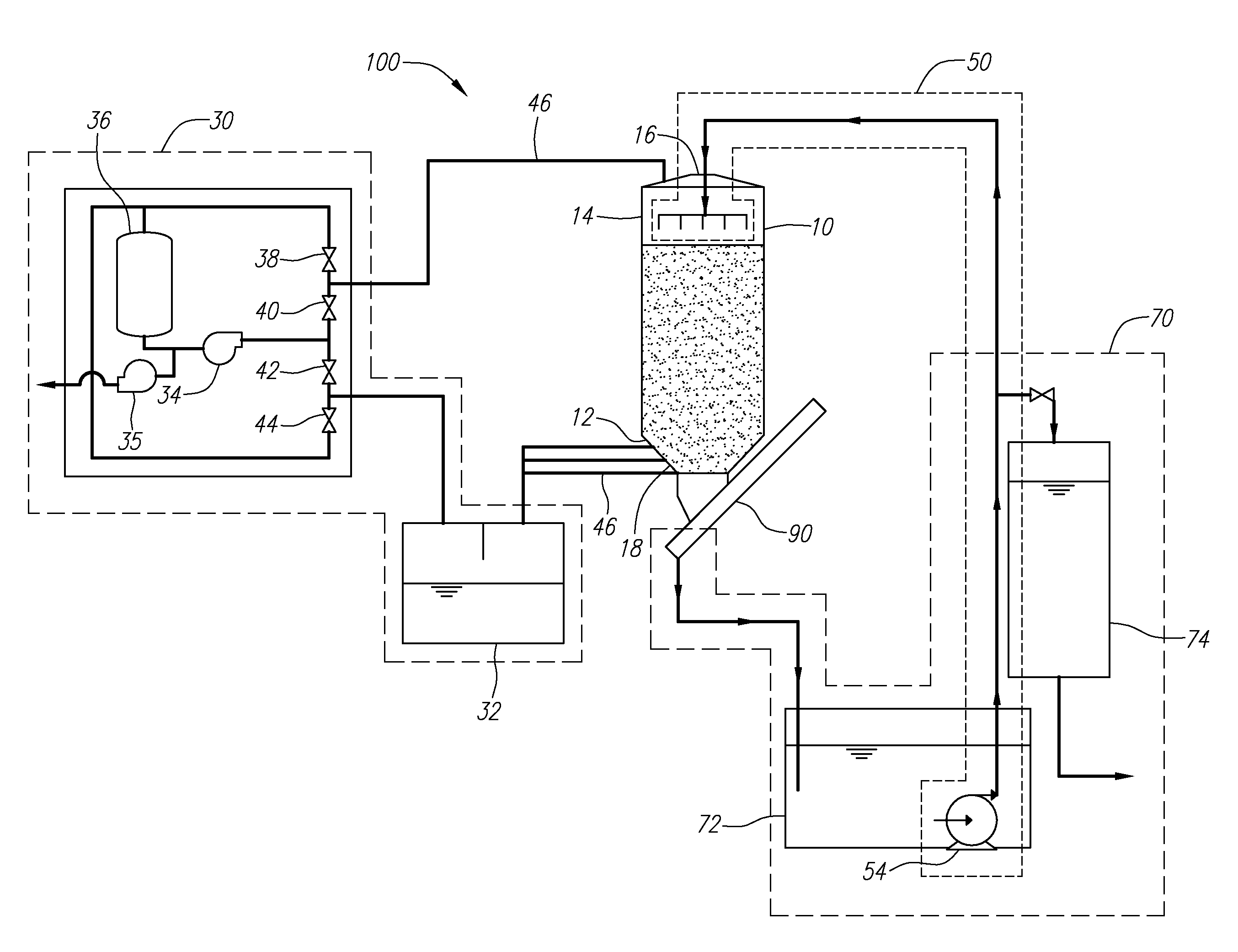

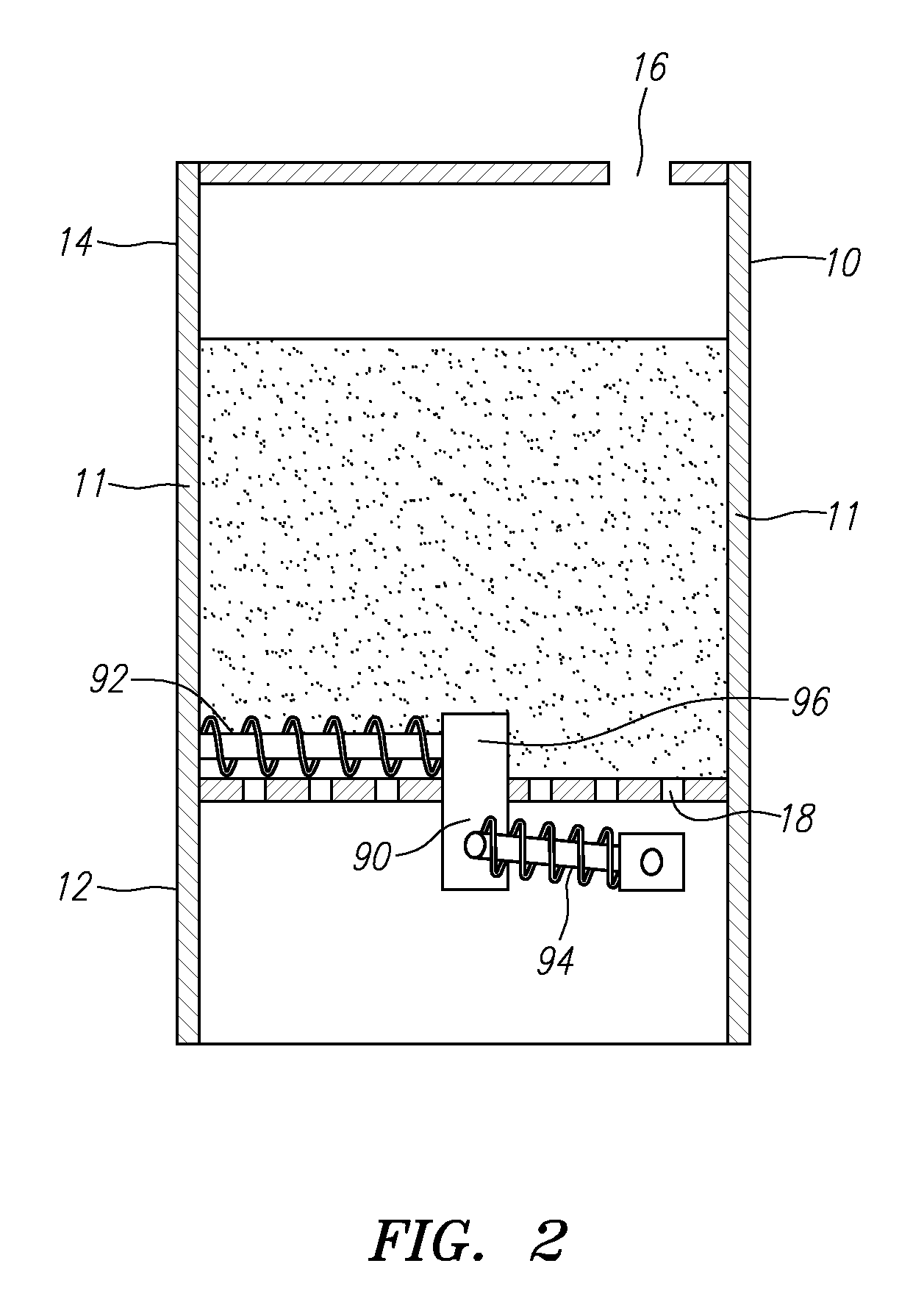

[0063]FIG. 1 illustrates a schematic view of a bioreactor for performing stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com