Firearm with facility for open-bolt and closed-bolt operation

a technology of closed-bolt operation and open-bolt, which is applied in the field of selectfire rifles, can solve the problems of increased susceptibility to dirt and contamination entering the action and chamber, increased risk of malfunction, and less accurate aimed fire of open-bolt arms, so as to avoid the noise of bolt closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

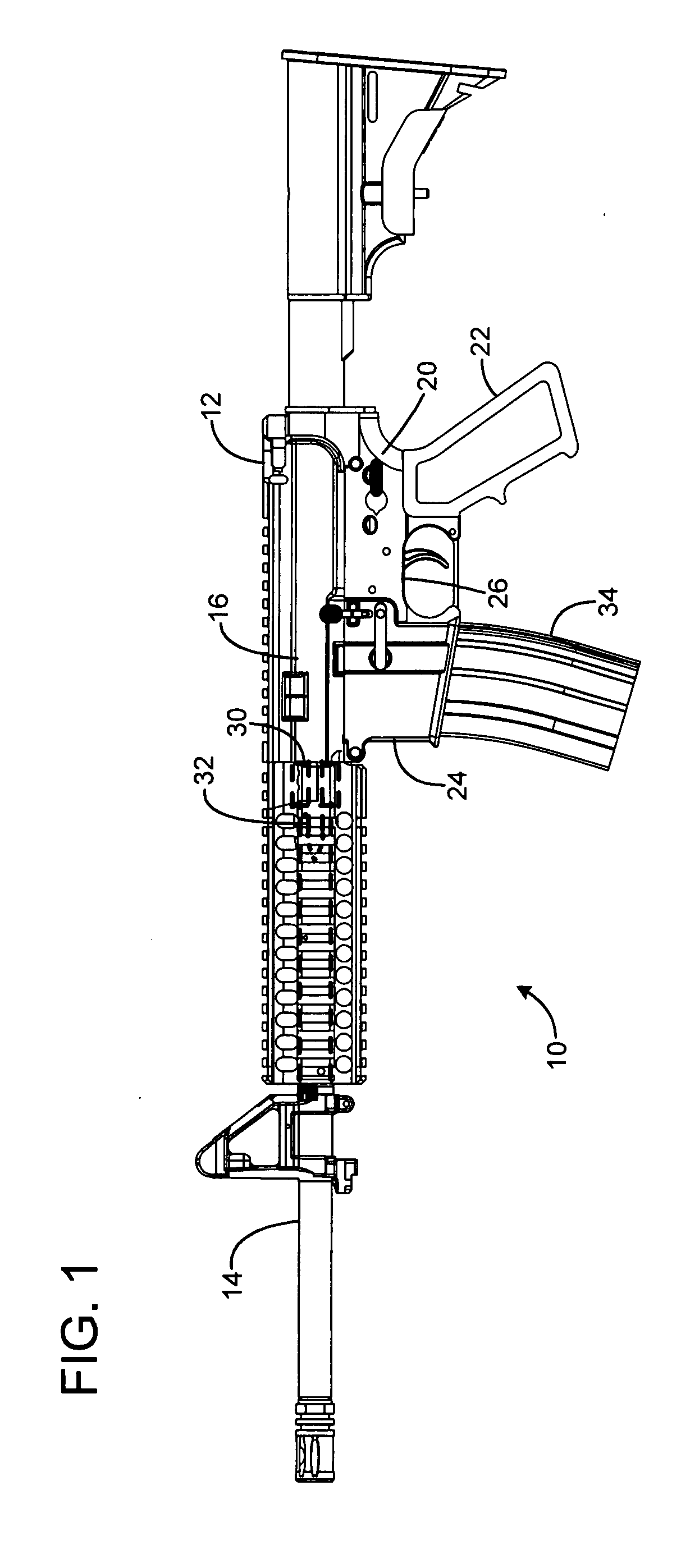

[0016]FIG. 1 shows a select fire rifle 10 in the pattern of an M-16, AR15, M4 or AR10. The rifle has an upper receiver 12 that contains a barrel 14, and a reciprocating bolt assembly 16 (which may also be referred to as a “bolt”). The rifle has a lower receiver 20 having a grip 22, magazine well 24, and a housing portion 26 in which fire control elements reside, as will be discussed below. The barrel has a rear end 30 defining a chamber 32 into which cartridges are fed from a detachable magazine 34 during operation.

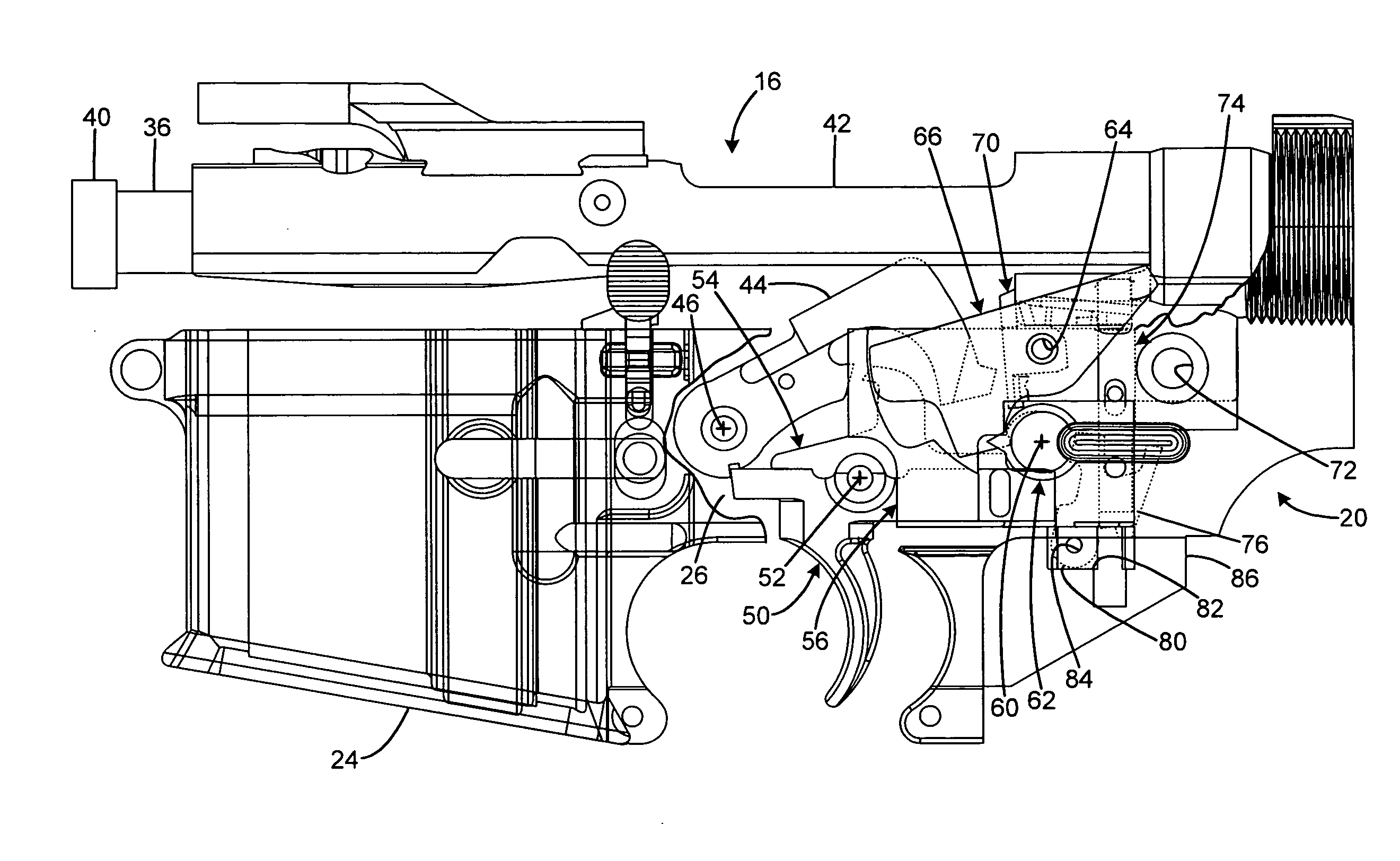

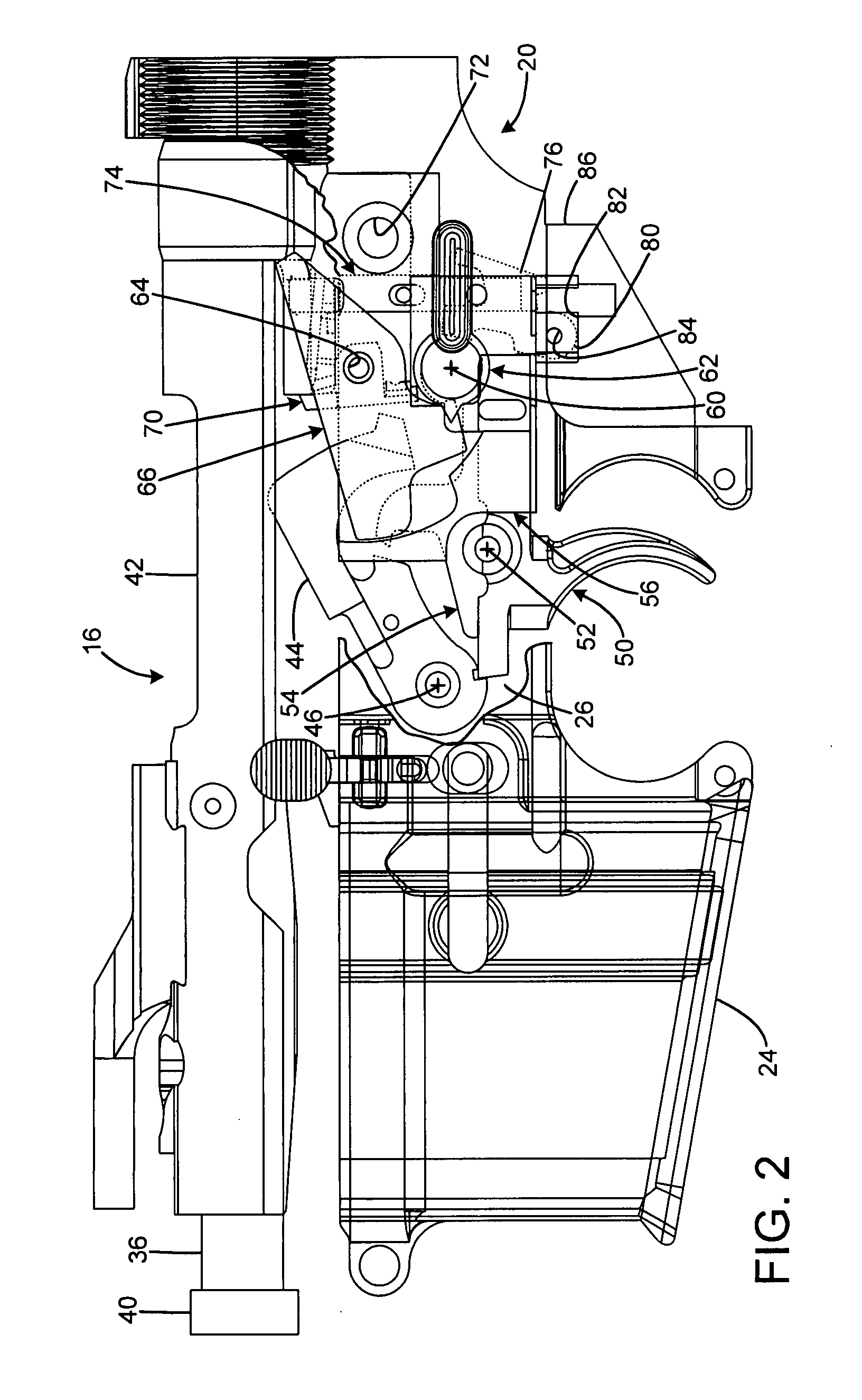

[0017]FIG. 2 shows the lower receiver 20 in greater detail, with certain conventional rifle parts omitted. The bolt assembly 16 includes a bolt 36 having a bolt head 40 that protrudes forwardly for interaction with the barrel 14. The bolt reciprocates within a bolt carrier 42. The bolt assembly reciprocates between a forward position (shown) in which the bolt head engages the chamber, and a rearward position in which the bolt head is to the rear of the magazine well, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com