Method for production of polypeptide

a polypeptide and polypeptide technology, applied in the field of polypeptide production, can solve the problems of not producing hamster cysteine dioxygenase, cysteine sulfinic acid decarboxylase, -alanine is produced, etc., and achieve the effect of increasing the yield of the desired polypeptid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Cloning of CHO Cell-Derived Hamster Cysteine Sulfinic Acid Decarboxylase (CSAD) and Cysteine Dioxygenase, Type I (CDO1) Genes

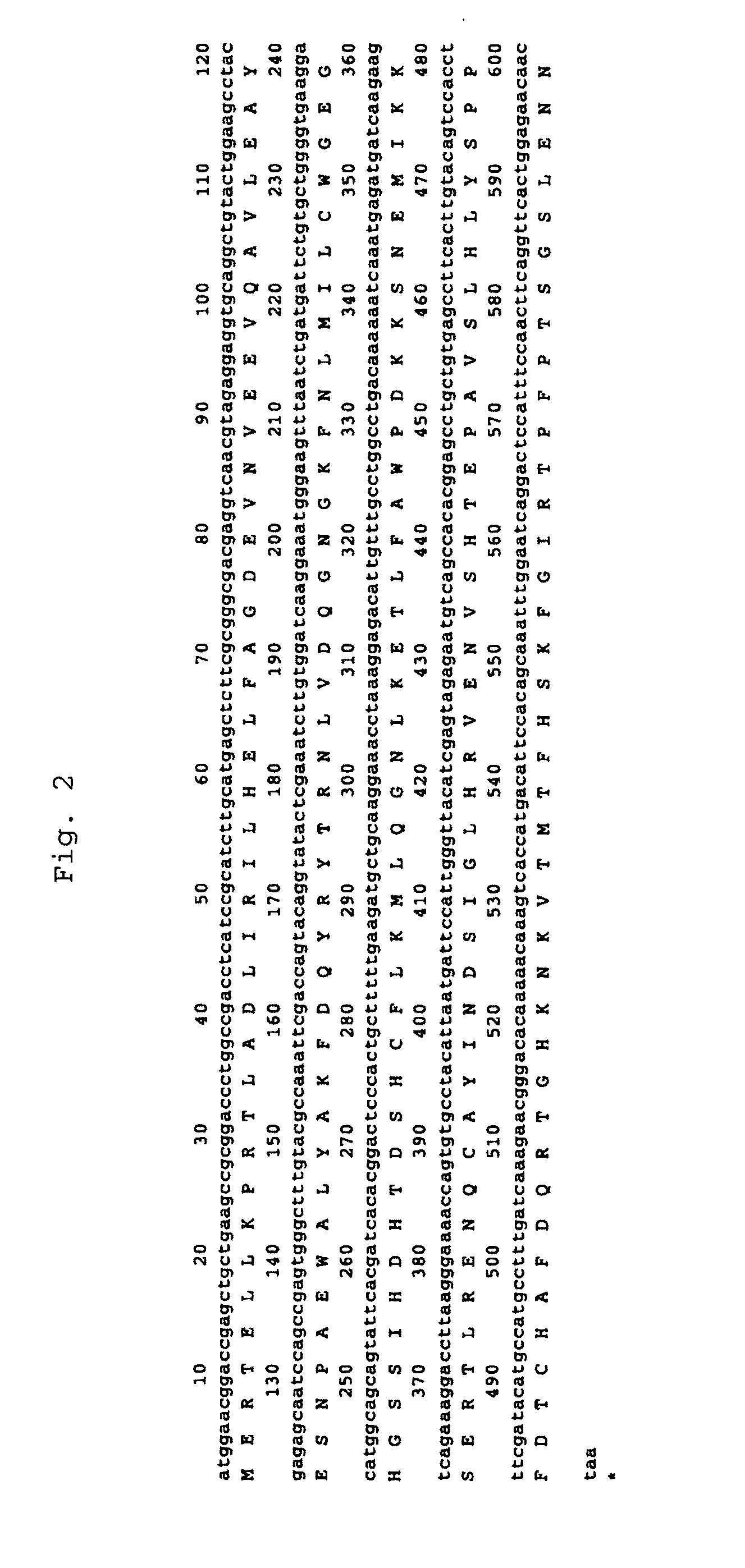

[0178]Total RNA was extracted from anti-IL-6 receptor antibody-producing cells (A CHO DXB11 cell line into which an anti-IL-6 receptor antibody gene had been transferred) (Japanese Unexamined Patent Publication No. Hei 8-99902), and then cDNA was synthesized therefrom in a poly(A) dependent manner. Hamster CSAD and CDO1 genes were obtained by PCR using as a template the cDNA fragmented with three restriction enzymes, SalI, XhoI and EcoRI. As PCR primers, those containing the 5′-end and the 3′-end sequence conserved between rat and mouse CSADs or CDO1s were designed. The nucleotide sequences of the cloned genes were determined. From its homology with other CSAD or CDO1 genes of known species, the cloned gene was confirmed to encode hamster CASD (FIG. 1) or CDO1 (FIG. 2). The amino acid sequence of hamster CSAD has high homology with the known amino acid sequenc...

example 2

Increase in Antibody Yield, Inhibition of Lactate Production and Maintenance of Survival Ratio, as Caused by Transfer of Hamster CSAD

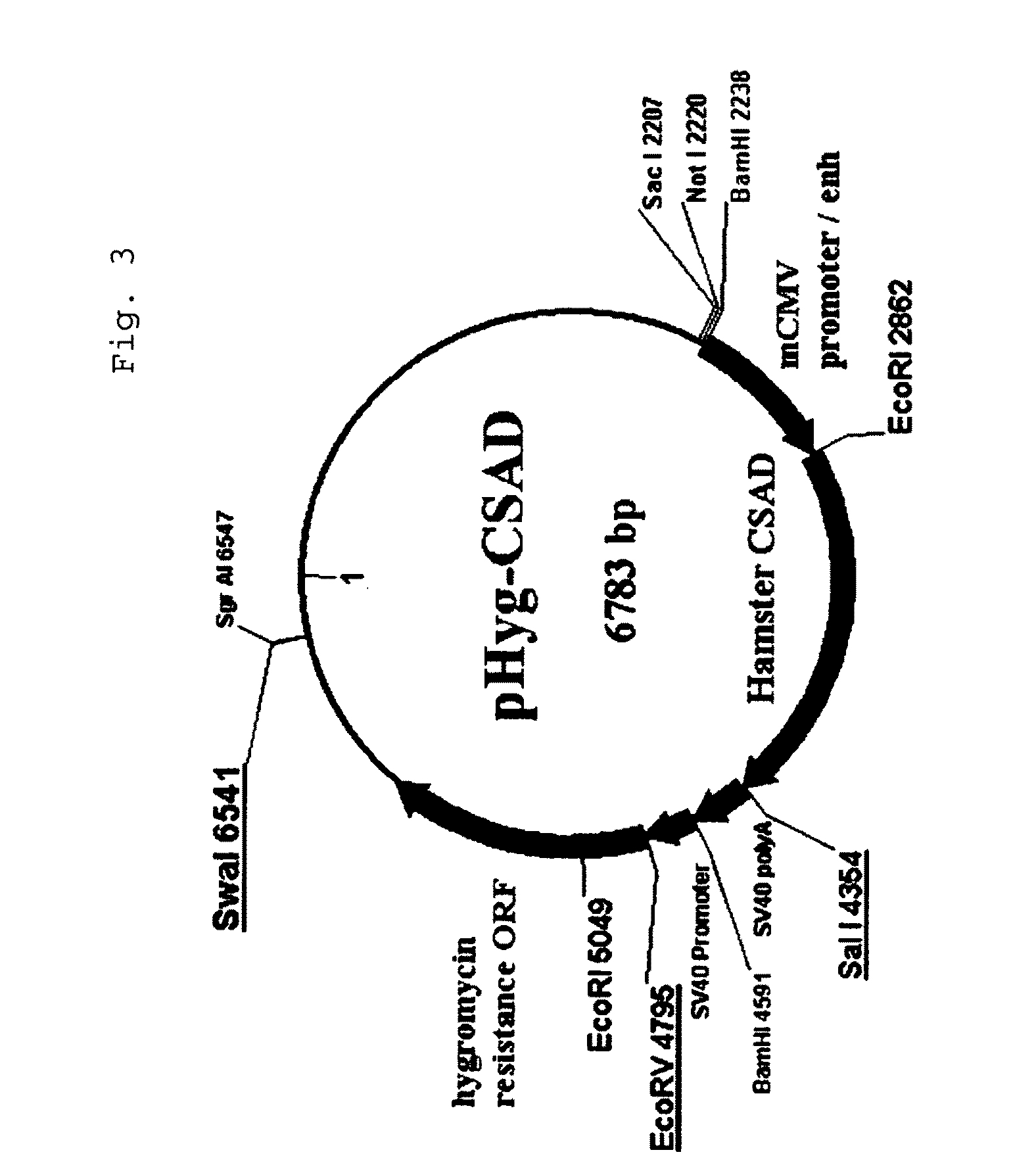

[0179]CMV promoter expression plasmid pHyg / CSAD (FIG. 3) or pHyg / CDO1 (FIG. 4) was constructed by adding Kozak sequence to the hamster CSAD (hereinafter, CSAD) or the hamster CDO1 (hereinafter, CDO1) gene obtained by cloning in Example 1. The plasmid pHyg / CSAD or pHyg / CDO1 was introduced by electroporation into the parent strain anti-glypican-3 antibody producing CHO cell (see WO 2006 / 006693). After selection of expression plasmid-transferred cells in the presence of hygromycin (200 μg / ml), all of the stably growing cell strains were expanded (pHyg / CSAD: 7 strains; pHyg / CDO1: 6 strains). The mRNA expression levels of CSAD and CDO1 were quantified by a TaqMan method. The two strains were confirmed to express mRNA at levels superior to that with the parent strain (in both CSAD and CDO1, the mRNA expression was 200 times or greater than that of the parent...

example 3

Survival Ratio-Maintaining Effect in the Presence of β-alanine

[0183]The parent strain and the CSAD-transferred strain were subjected to batch culture in a 50-ml shaker (2×105 cells / mL in an initial stage) in the presence or absence of β-alanine (25 mM), and a comparison was made for their survival ratio. As FIG. 14 shows, on the 6th day of the culture, the survival ratio of the CSAD-transferred strain capable of high-yield production of β-alanine was maintained in the absence of β-alanine (0 mM). In contrast, on the 6th day of the culture, the survival ratio of the parent strain in capable of high-yield production of β-alanine decreased in the absence of β-alanine. The survival ratio of the parent strain on the 6th day of the culture was maintained in the presence of β-alanine (25 mM), demonstrating the survival ratio maintaining effect of addition of β-alanine. However, from the survival ratio of the CSAD-transferred strain on the 7th day of the culture, it was found that the survi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com