Method for filling bottles or similar containers with an oxygen sensitive effervescent liquid beverage filling material under counterpressure and filling machine for the performance of this method

a technology of effervescent liquid beverage and filling material, which is applied in the direction of liquid handling, transportation and packaging, packaging goods types, etc., can solve the problems of inert gas that comprises air or oxygen from the additional duct not being able to enter the headspace of the bowl, and affecting the shelf life and quality of the liquid being bottled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

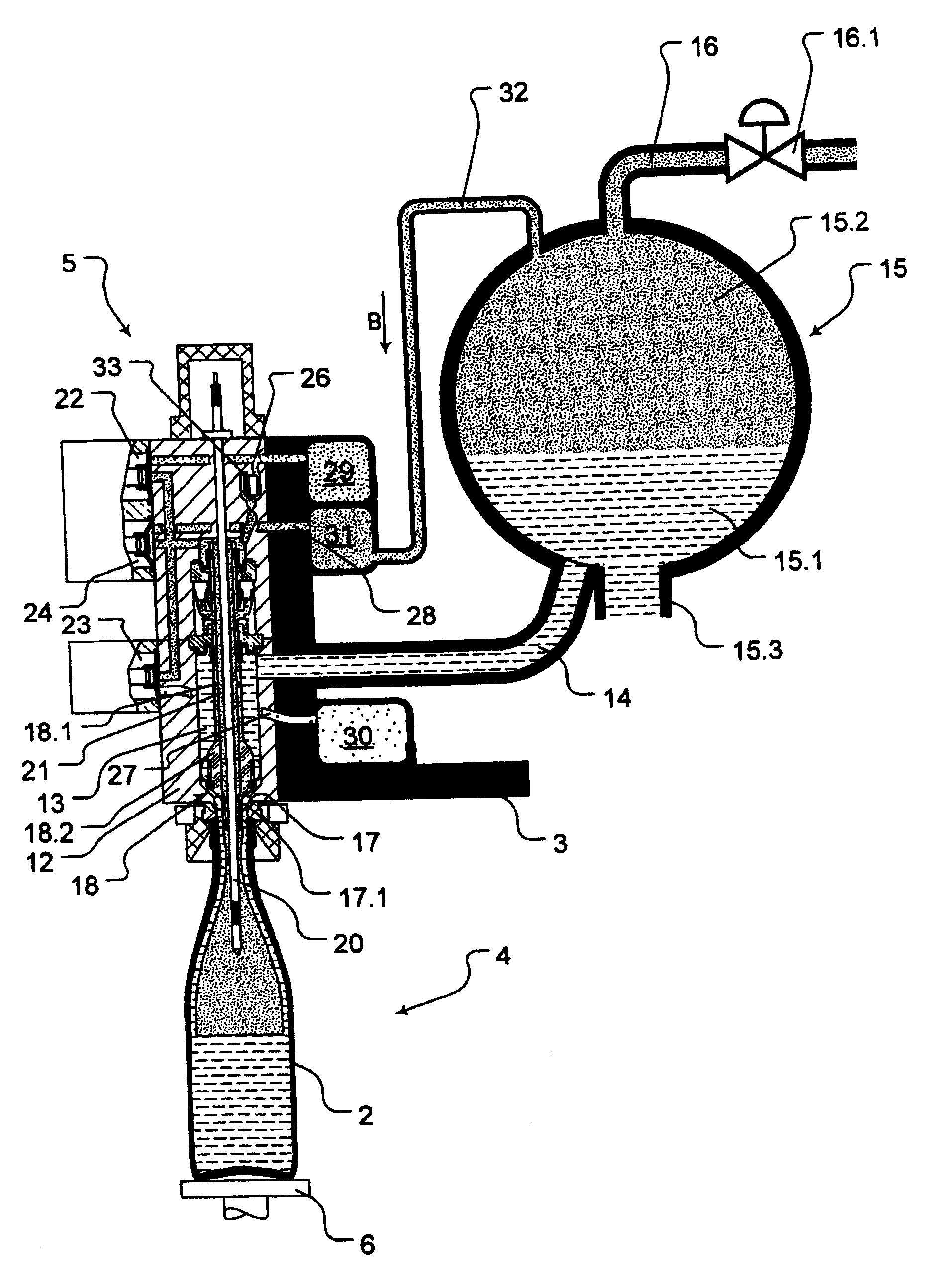

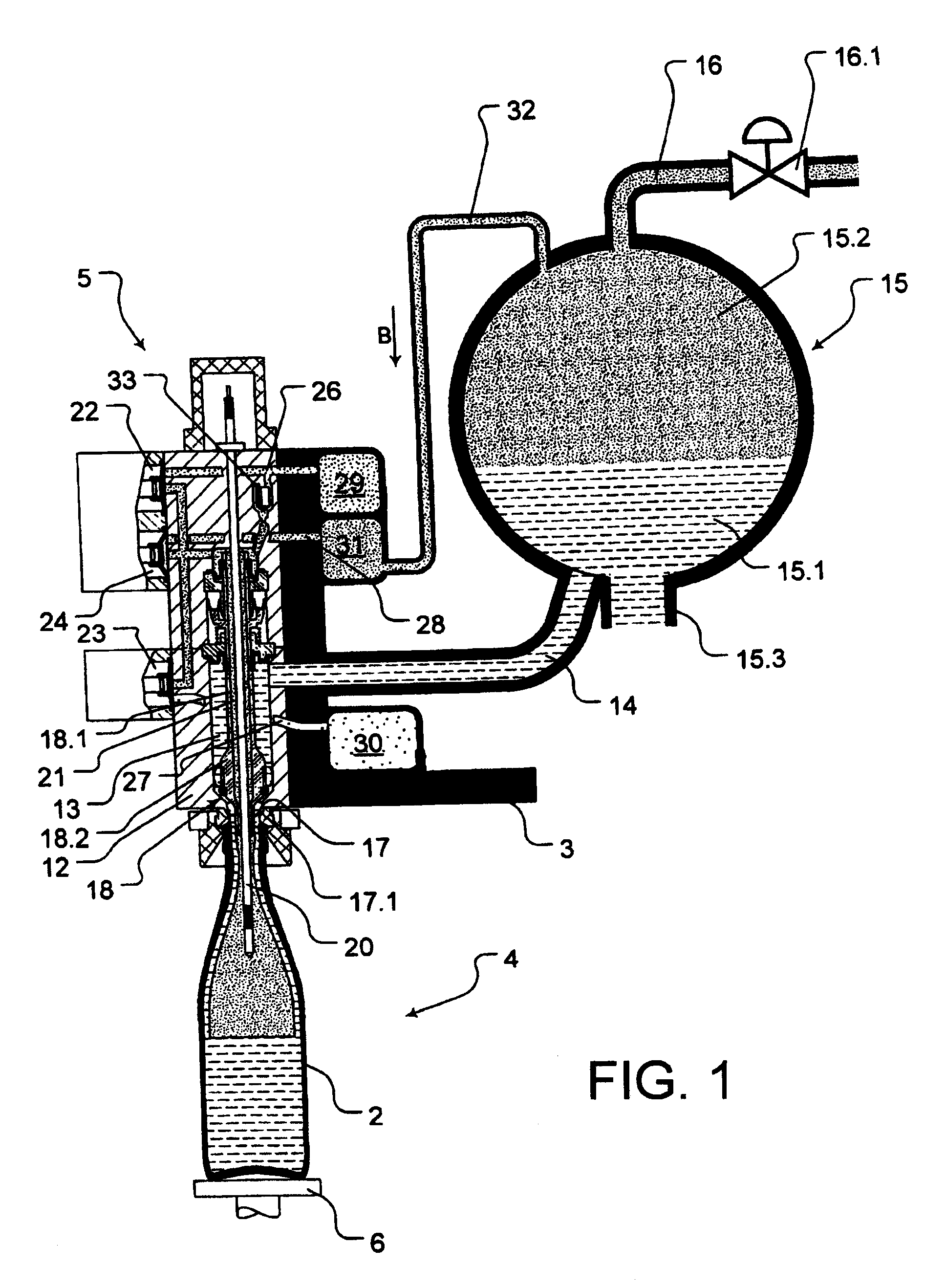

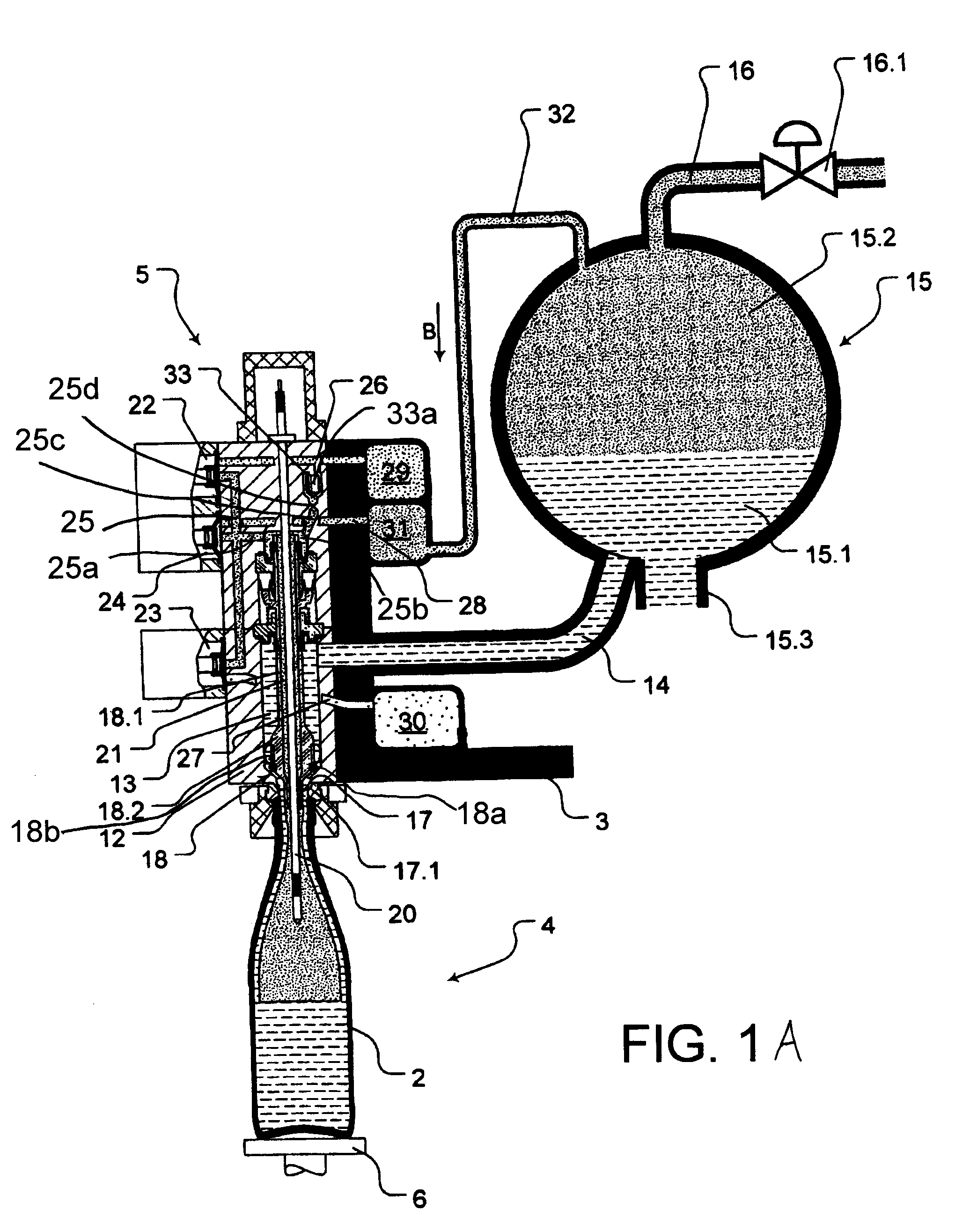

[0024]In the figures, 1 is a filling machine for the filling of containers realized in the form of bottles 2 with a liquid that houses carbon dioxide such as beer, for example. For this purpose, the filling machine 1 has, and distributed at equal intervals on the periphery of a rotor 3 which is driven in rotation (Arrow A) around a vertical machine axis, a plurality of filling stations 4, each of which comprises a filling element 5, which does not have a filling tube in the illustrated embodiment, and a bottle or container carrier 6 which is located underneath this filling element 5 in the form of a bottle plate that can be raised and lowered in a controlled manner by a lifting device.

[0025]The bottles 2 to be filled are delivered to the filling machine 1 in the upright position in the form of a container stream 2.1 via a conveyor 7, and each container arrives individually via a container inlet 8 at one of the filling positions 4, in which the respective bottle 2 is oriented with it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| saturation pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com