Automotive Heater Core

a heater core and heater core technology, applied in the direction of heat exchanger fastening, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of leakage and failure of the heater core, affecting the effective cooling area, appearance and quality of products, and comparatively low overall angular rigidity of the heater core. , to achieve the effect of good brazing, increased friction between the cooling fins and side plates, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

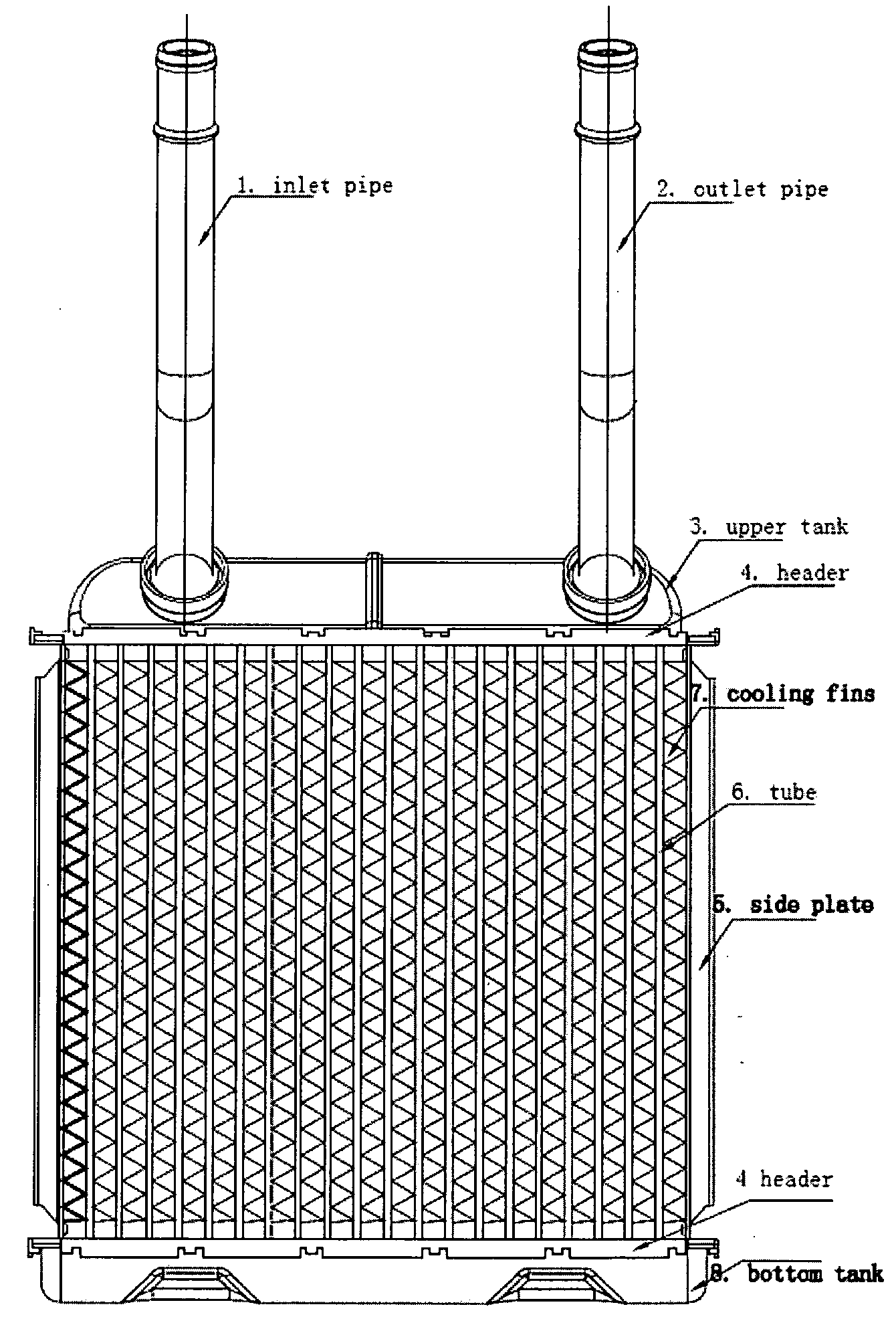

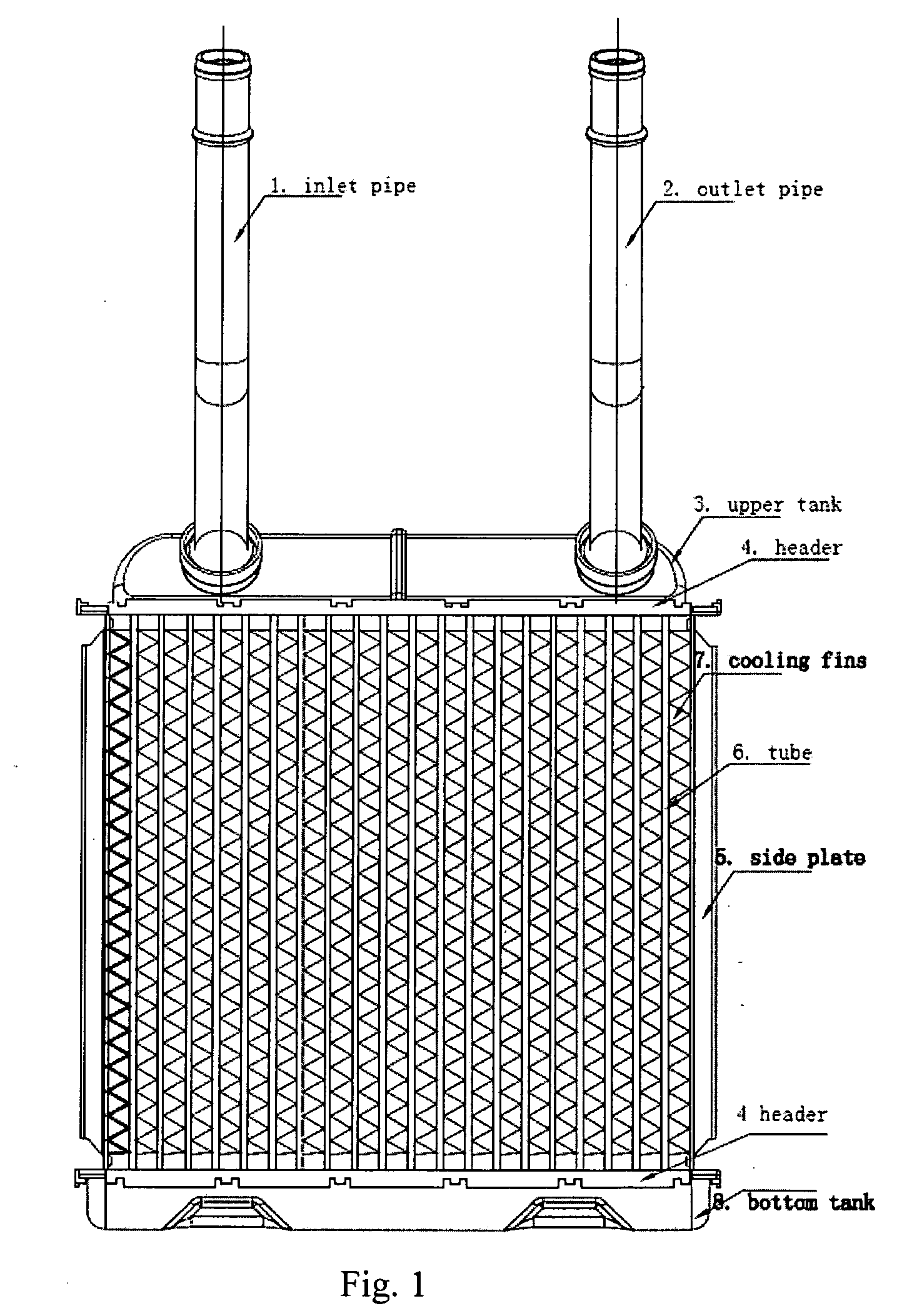

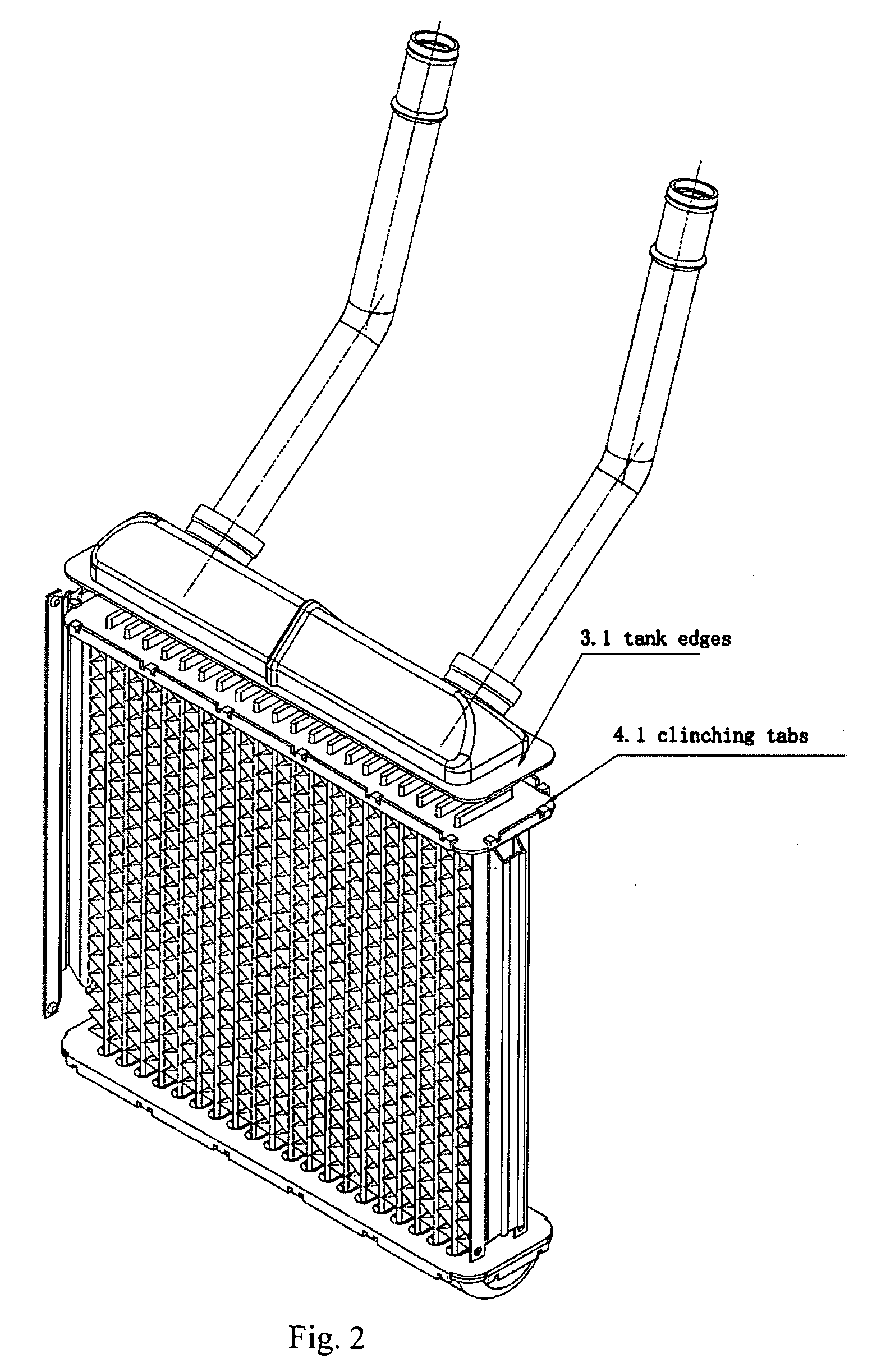

[0030]In reference to FIG. 1, an automotive heater core includes eight parts: inlet pipe 1, outlet pipe 2, upper tank 3, bottom tank 8, header 4, tube 6, cooling fins 7 and side plate 5. Said header (4) has clinching tabs (4.1) around the headers connecting to the upper tank (3) and to the bottom tank (8) as shown in FIG. 2, 3, 4, 5. When assembling said clinching tabs 4.1 are clamped to the edges 3.1 of the upper 3 and bottom tanks 8 for brazing, as shown in FIGS. 6 and 7. This type of clamping can be applied to the connection of header and tank of all heater cores and radiators for heavy duty applications.

[0031]Said side plates (5) have two button protuberances (5.1) or retaining tabs (5.2) at both ends of the side plates (5) where the cooling fins (7) end as shown in FIGS. 8, 9, 10 and 11, 12 (in FIGS. 8, 9, 10 there are 2 button protuberances 5.1 at each end of the side plates, in FIGS. 11, 12 there are 2 retaining tabs 5.2 at each end of the side plates.)

[0032]Said header (4) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com