Binding Structure between Tank and Header of Automotive Heater Core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

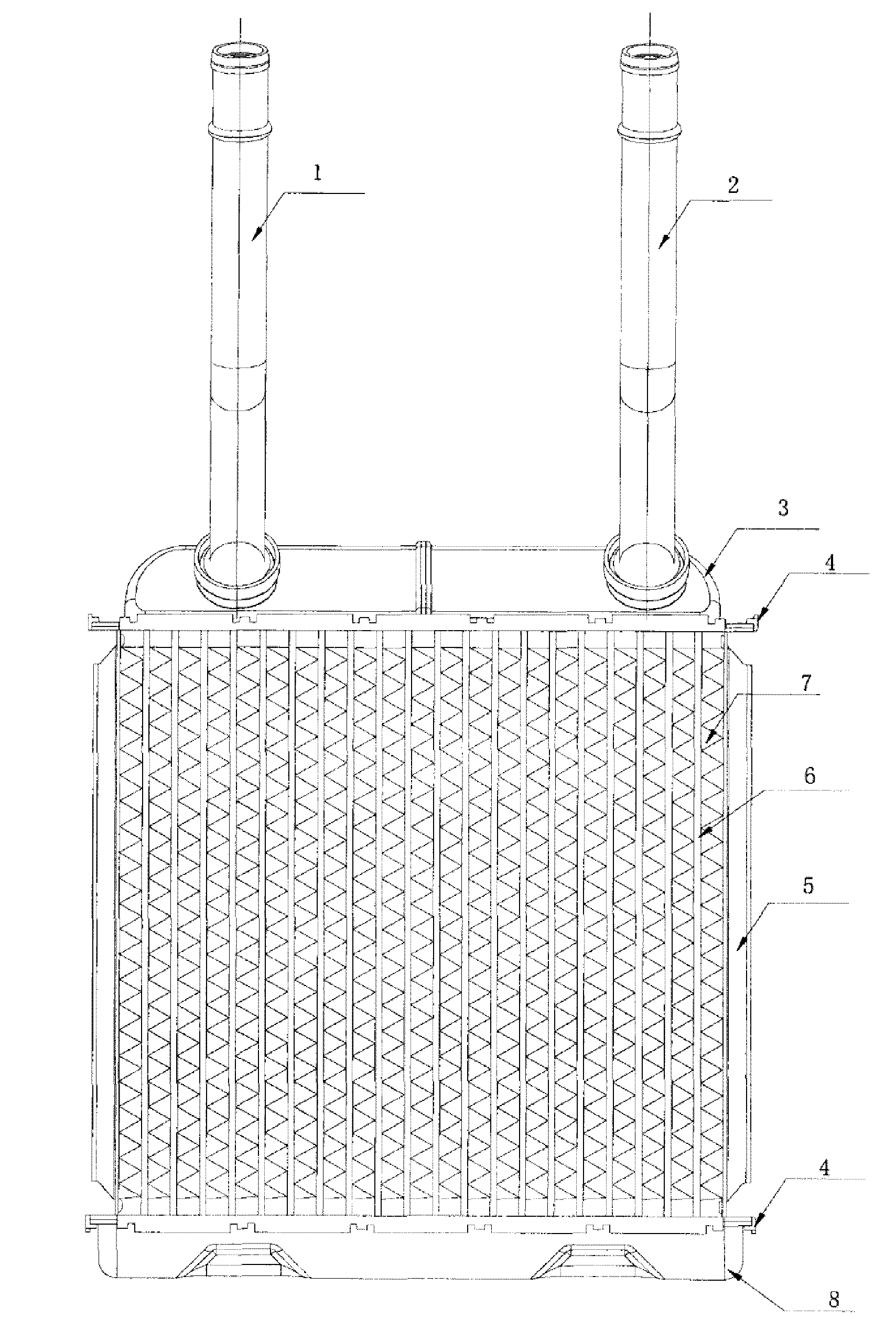

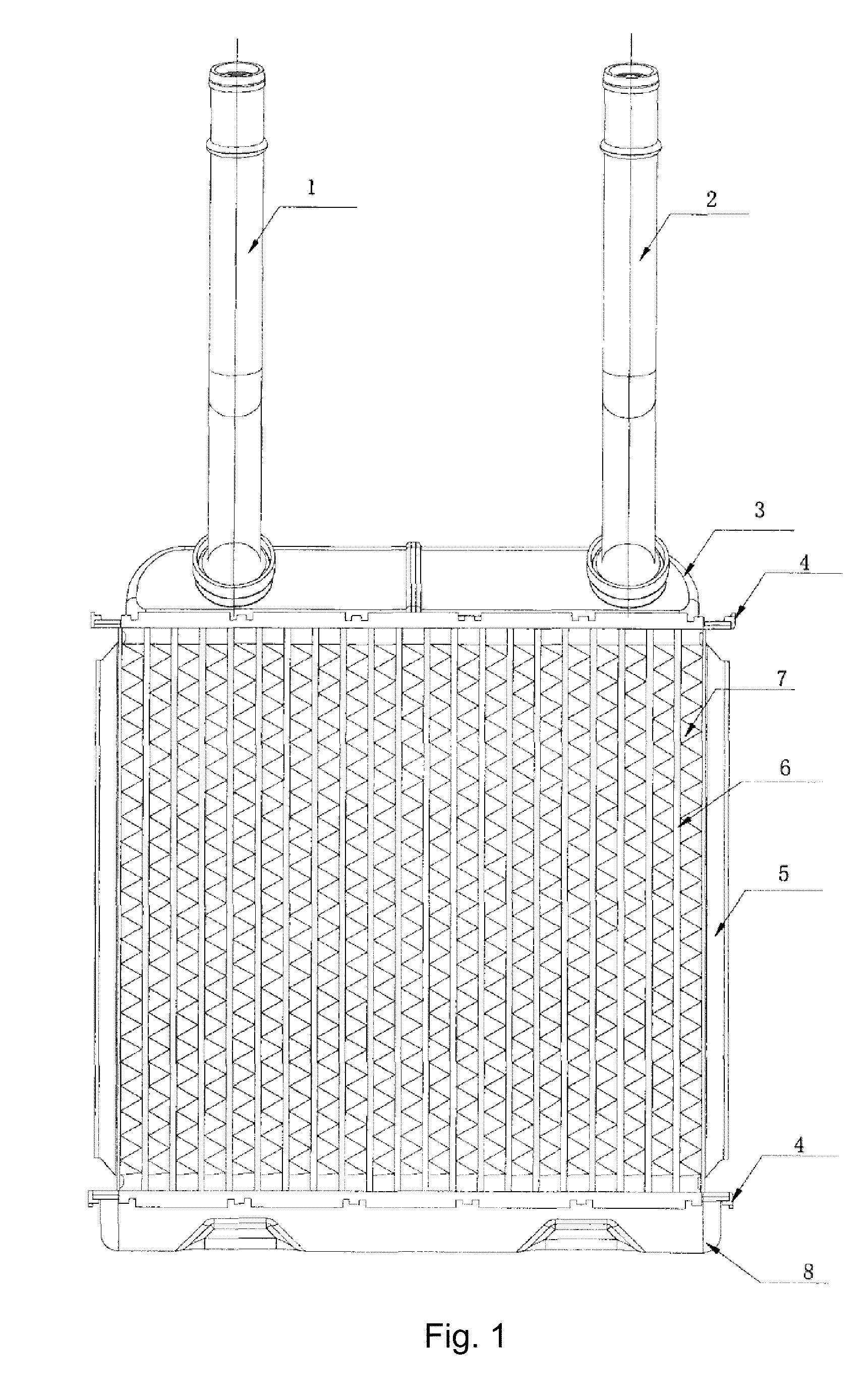

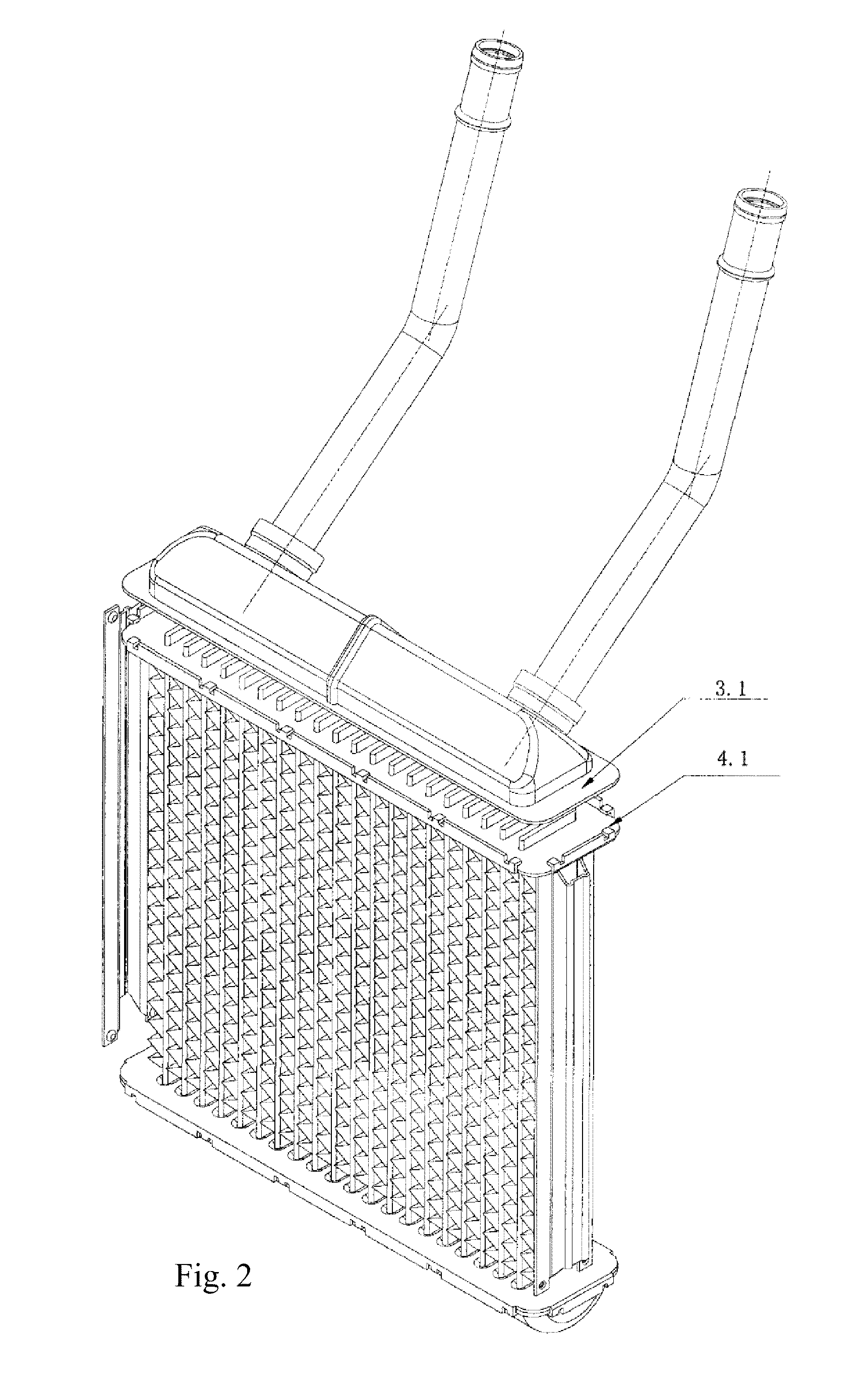

[0010]As shown in FIG. 1, an automotive heater core includes 8 parts: inlet pipe 1, outlet pipe 2, upper tank 3, bottom tank 8, header 4, tube 6, cooling fins 7 and side plate 5. As shown in FIGS. 2, 3, 4, 5 there are some clinching tabs (4.1) around the headers connecting to the upper tank (3) and to the bottom tank (8), when assembled the clinching tabs (4.1) clamp to the edges of the upper tank (3) and the bottom tank (8), then the assembled heater core is brazed as shown in FIGS. 6, 7. This kind of structure can be applied to header and tank's connection in all types of automotive heater cores and industrial radiators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com