Soy protein products having altered characteristics

a technology of soy protein and characteristic, applied in the field of soy protein products, can solve the problems of protein material having strong beany, bitter taste and odor, and achieve the effects of improving whiteness, reducing gel strength, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Transformation of Soybean (Glycine max)

Embryo Cultures and Regeneration of Soybean Plants.

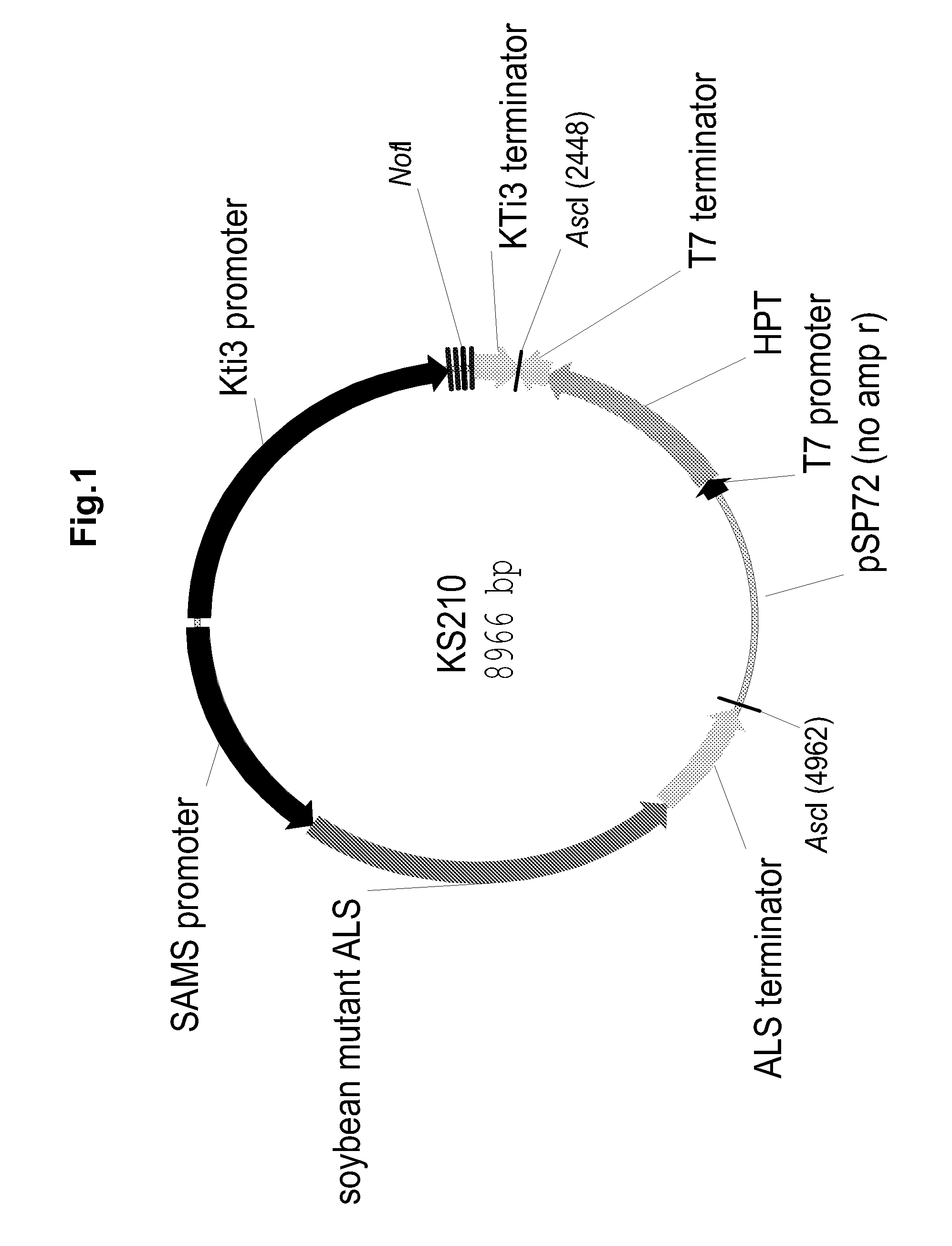

[0174]Soybean embryogenic suspension cultures are transformed by the method of particle gun bombardment using procedures known in the art (Klein et al. (1987) Nature (London) 327:70-73; U.S. Pat. No. 4,945,050; Hazel et al. (1998) Plant Cell. Rep. 17:765-772; Samoylov et al. (1998) In Vitro Cell Dev. Biol.-Plant 34:8-13). In particle gun bombardment procedures it is possible to use purified 1) entire plasmid DNA or, 2) DNA fragments containing only the recombinant DNA expression cassette(s) of interest.

[0175]Stock tissue for transformation experiments are obtained by initiation from soybean immature seeds. Secondary embryos are excised from explants after 6 to 8 weeks on culture initiation medium. The initiation medium is an agar-solidified modified MS (Murashige and Skoog (1962) Physiol. Plant. 15:473-497) medium supplemented with vitamins, 2,4-D and glucose. Secondary embryos are placed in fl...

example 2

Fatty Acid Analysis of Soybeans

[0177]In order to determine altered fatty acid composition as a result of suppression of the fatty acid desaturase, the relative amounts of the fatty acids, palmitic, stearic, oleic, linoleic and linolenic, can be determined as follows. Fatty acid methyl esters are prepared from single, mature, somatic soybean embryos or soybean seed chips by transesterification. One embryo, or a chip from a seed, is placed in a vial containing 50 μL of trimethylsulfonium hydroxide and incubated for 30 minutes at room temperature while shaking. After 30 minutes 0.5 mL of hexane is added, the sample is mixed and allowed to settle for 15 to 30 minutes to allow the fatty acids to partition into the hexane phase. Fatty acid methyl esters (5 μL from hexane layer) are injected, separated, and quantified using a Hewlett-Packard 6890 Gas Chromatograph fitted with an Omegawax 320 fused silica capillary column (Supelco Inc., Cat#24152). The oven temperature is programmed to hold...

example 3

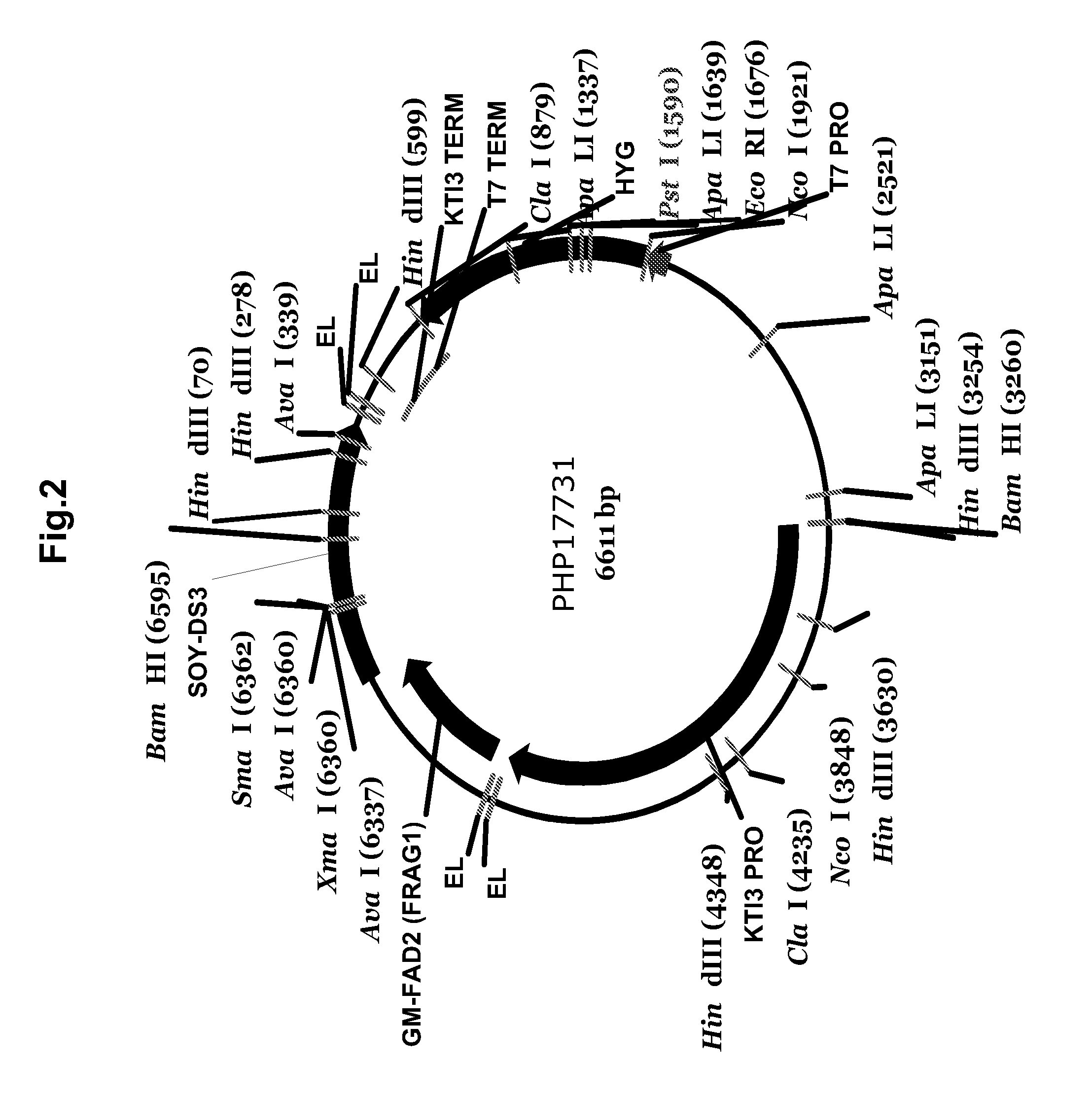

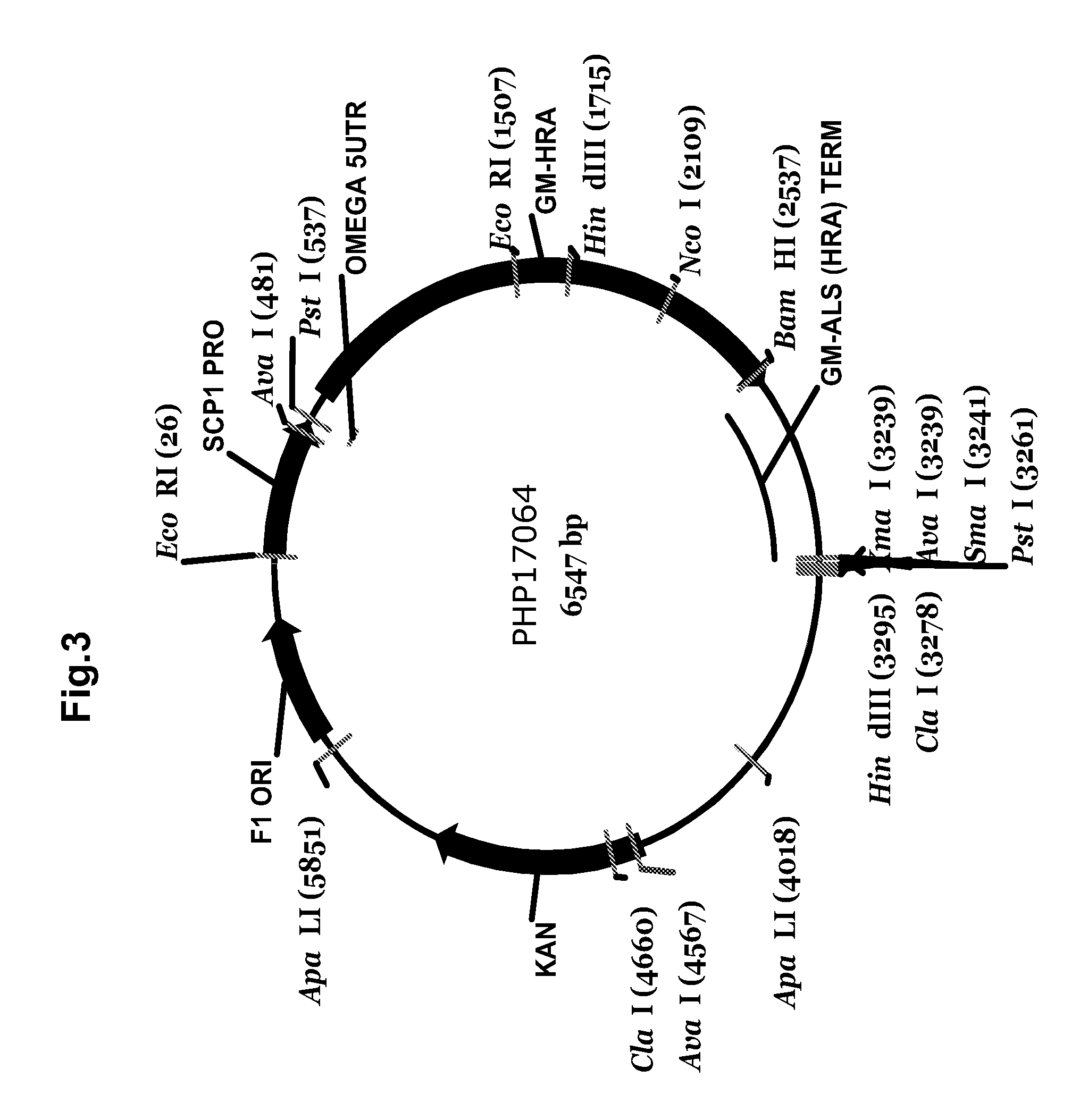

Production of Soybeans with High Levels Oleic Acid and / or High Levels of Stearic Acid and / or Low Levels of Polyunsaturated Fatty Acids by Suppression of Fatty Acid Desaturases

[0178]Recombinant DNA fragments were prepared and used in transformation of soybean for the simultaneous suppression of fatty acid desaturases FAD2-1 and FAD2-2 and fatty acid desaturase FAD3. A description of the construction of the recombinant DNA fragments follows.

A. Recombinant DNA Fragment PHP21676A

[0179]Recombinant DNA fragment PHP21676A contains a gene expression silencing cassette designed to silence expression of the FAD2-1 and FAD2-2 genes, and the FAD3 gene, linked in a head to head configuration to the ALS selectable marker recombinant DNA fragment of Example 1D below. The nucleotide sequence of recombinant DNA fragment PHP21676A is shown in SEQ ID NO:1. Recombinant DNA fragment PHP21676A contains in 5′ to 3′ orientation:[0180]a) the complementary strand of the ALS selectable marker recombinant DNA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com