Prosthetic limb with replaceable fairing

a prosthetic limb and fairing technology, applied in non-surgical orthopedic devices, instruments, medical science, etc., can solve the problems of less thought given to the aesthetics of the human being for whom the device was intended, neglecting the fundamental symmetry of the human form, and asymmetric appearance of the prosthetic limbs are more troublesome than physical discomfort, so as to achieve easy change, improve the appearance of a portion, and improve the strength of the prosthetic limb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

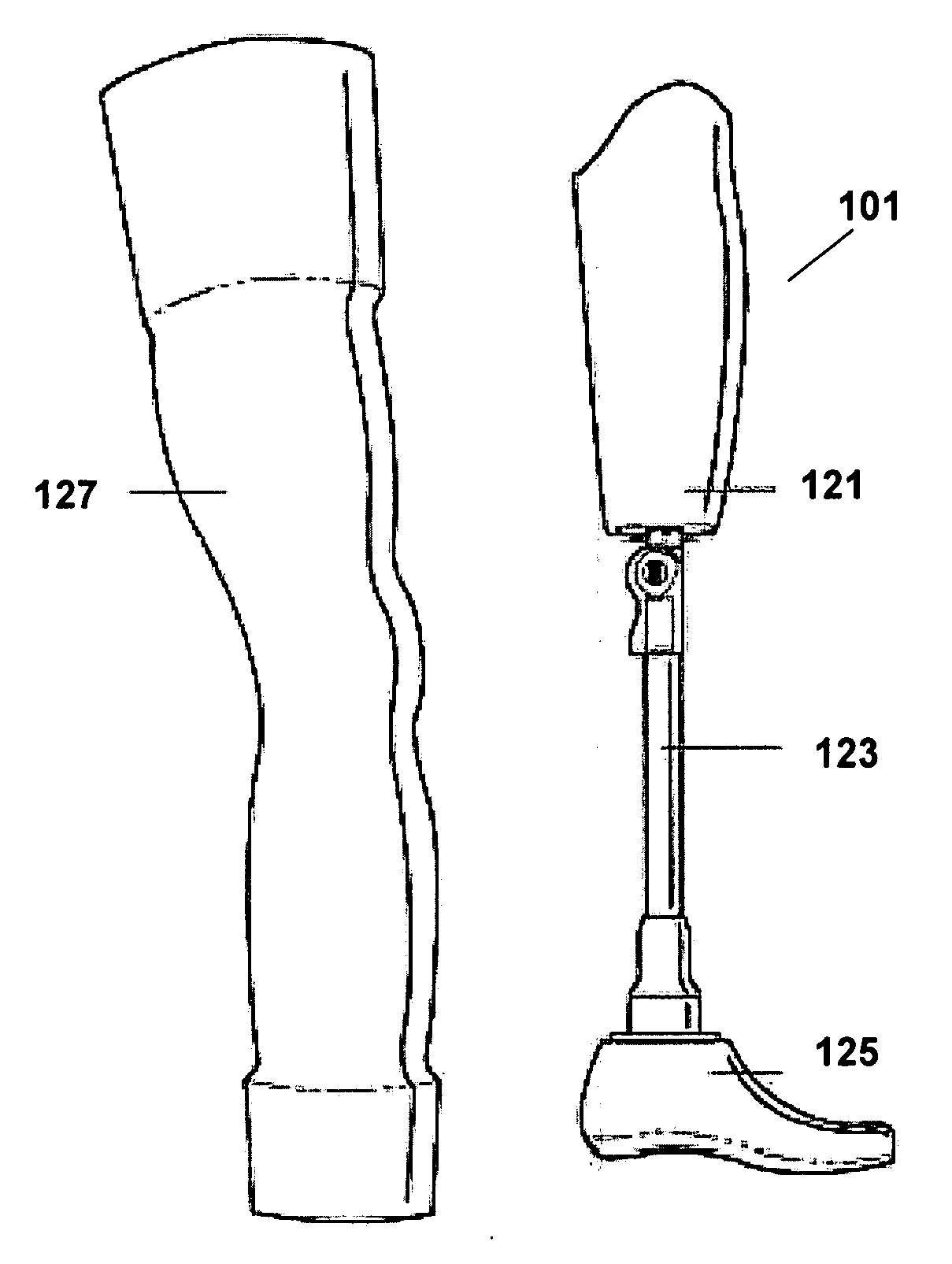

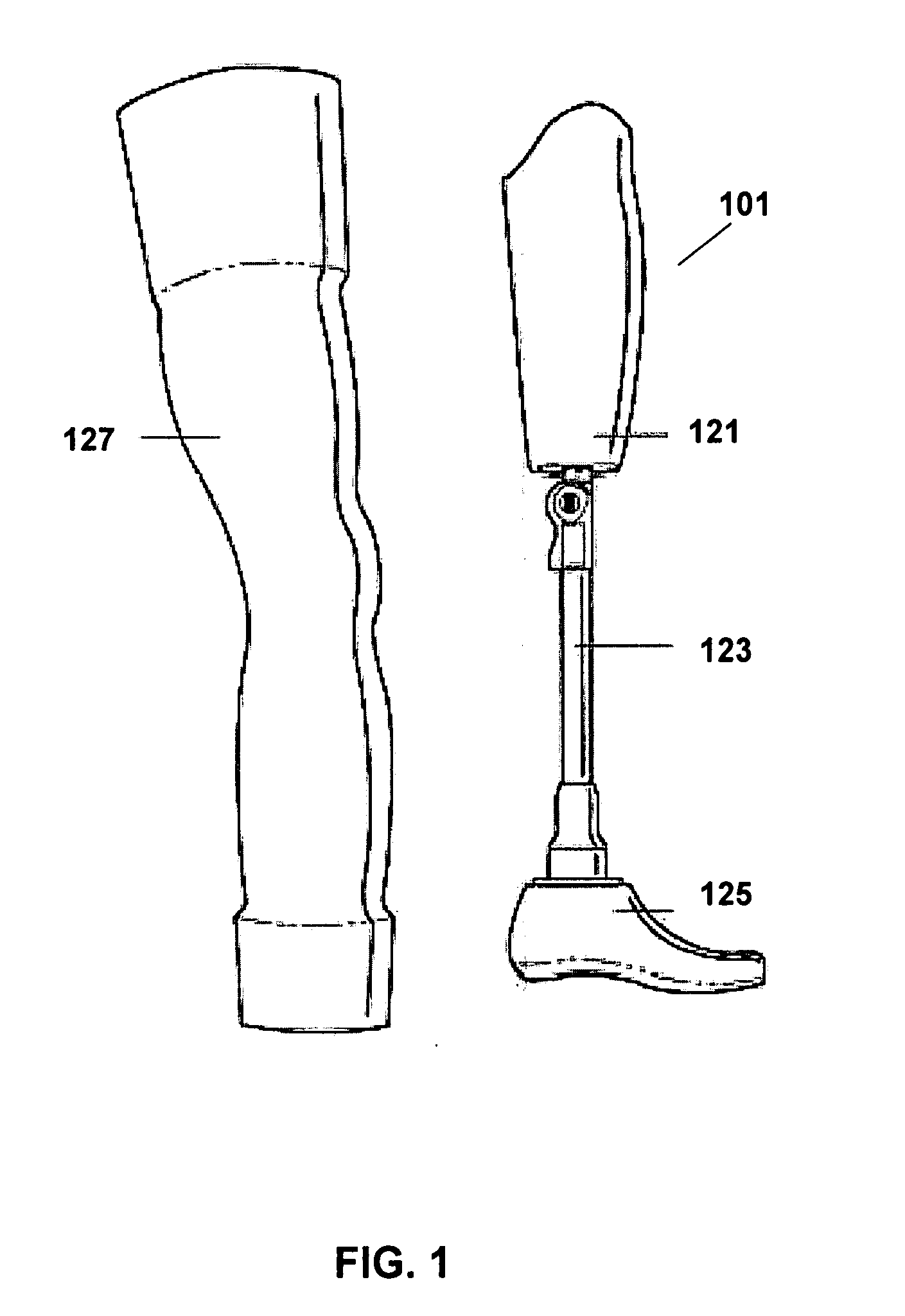

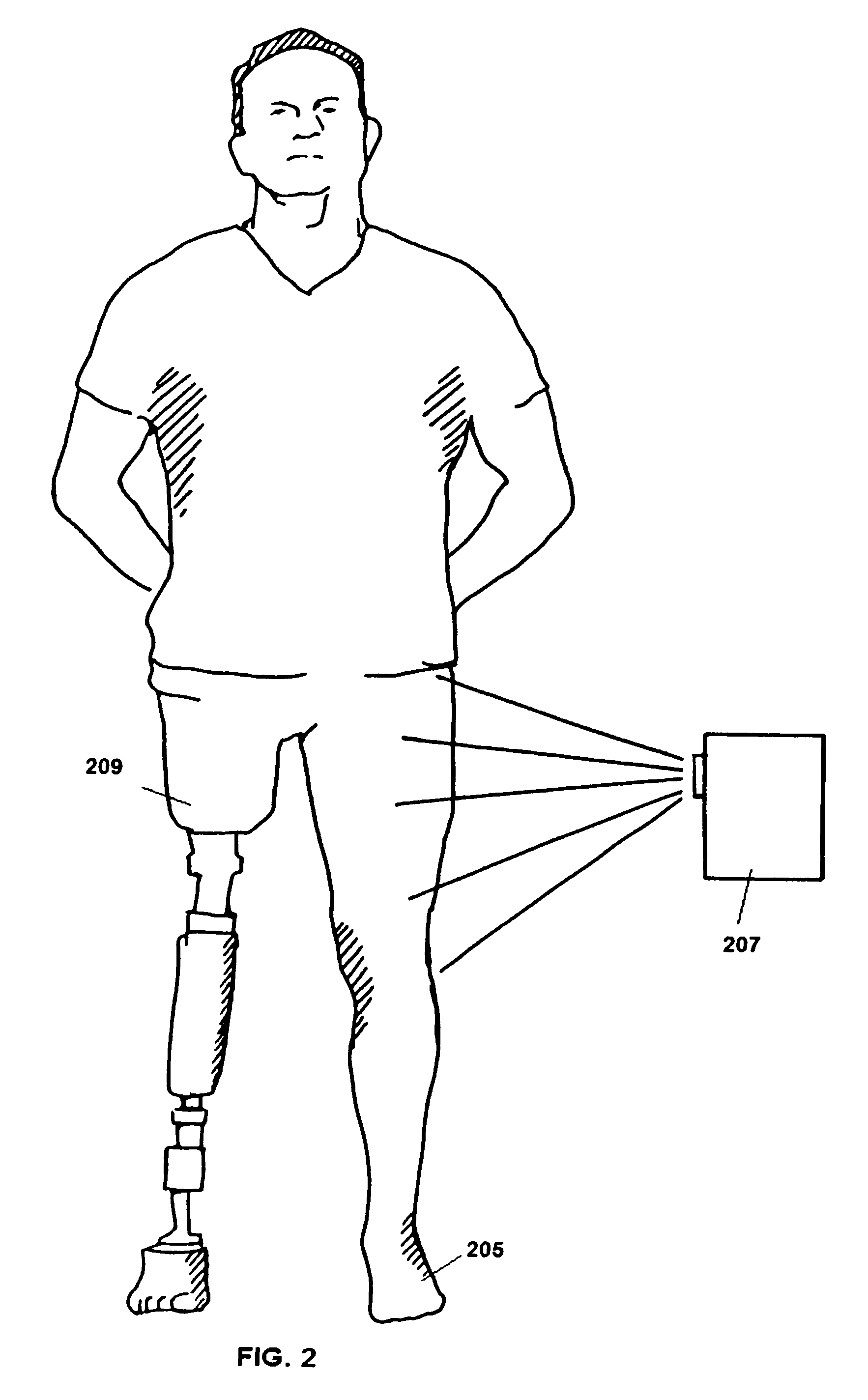

[0036]The present invention is a prosthetic limb having an exterior surface that matches the surface contours of a human limb. The prosthetic limb emulates the contours of the original limb by referencing surface geometry drawn from the sound side limb. The exterior surface can also be modified so a user can alter the appearance of the prosthetic limb. A replaceable fairing can be designed to cover a portion of the prosthetic limb. The prosthetic limb and fairing are designed on a computer and the design data can be used to fabricate the prosthetic components using computer controlled fabrication machines. The inventive prosthetic limb is primarily directed towards prosthetic legs but the same design and fabrication processes can also be used to create prosthetic arms. The prosthetic limb is preferably designed by an industrial designer using a Computer Aided design (CAD) program.

[0037]The inventive prosthetic legs include a load bearing component that functions as the human tibia. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com