Internal combustion engine having exhaust gas bypassing control mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

[0041]Car as an object of experiment: Diesel passenger car

[0042]Type of car: “Bluebird” (trade mark) manufactured by Nissan Motor Co. Ltd. in 1992

[0043]Engine mounted: 4-cycle 4-cylinder diesel engine

[0044]Total engine displacement: 1973 cc

[0045]Engine power: 4800 rpm / min, 76 Hp (in the state of new car)

[0046]Fuel cost (heavy oil): about 12 km / liter

[0047]Residual diesel black smoke concentration in exhaust gas: 55%

[0048]Vibration of exhaust cylinder: Violent vertical and lateral vibrations were observed.

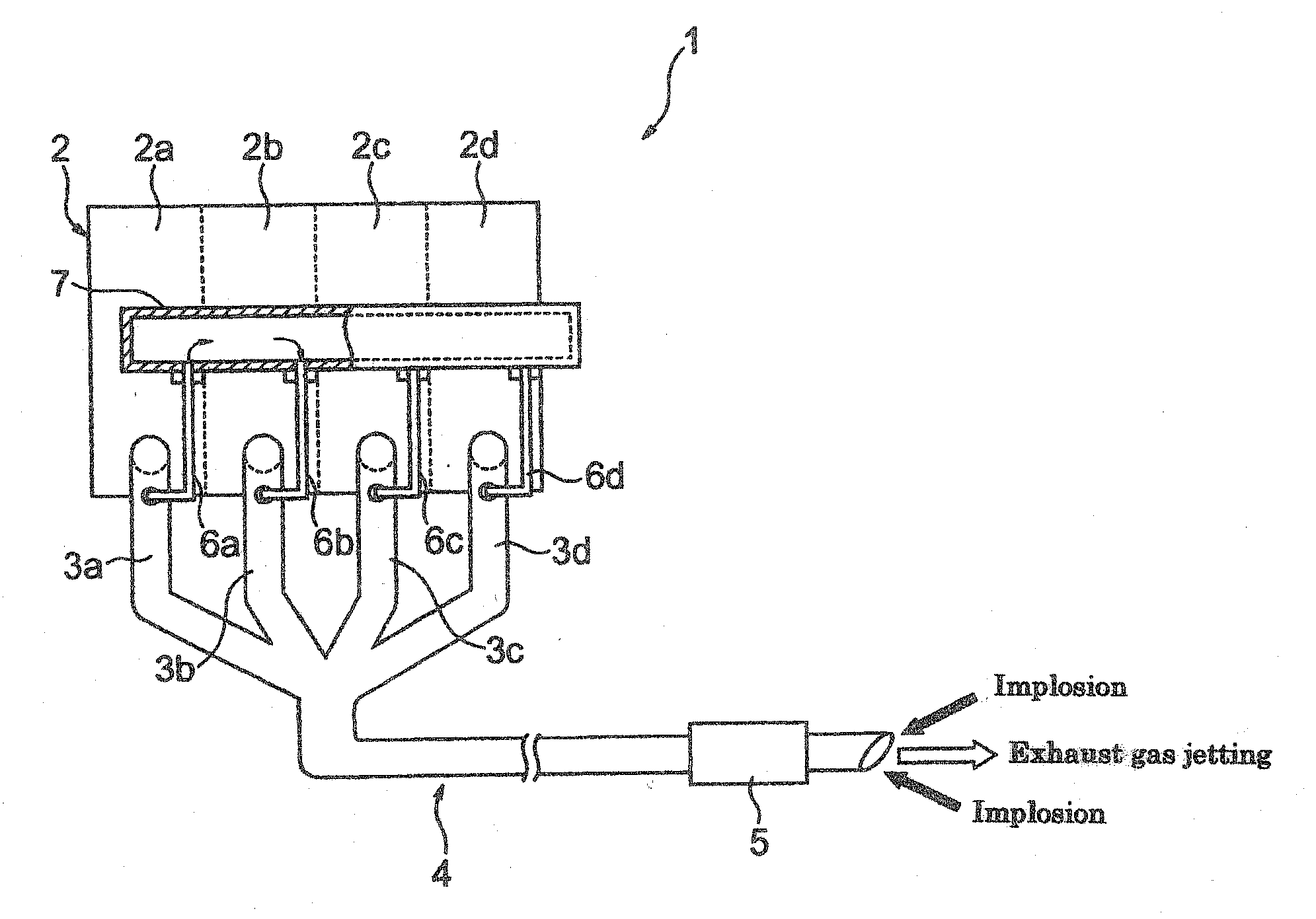

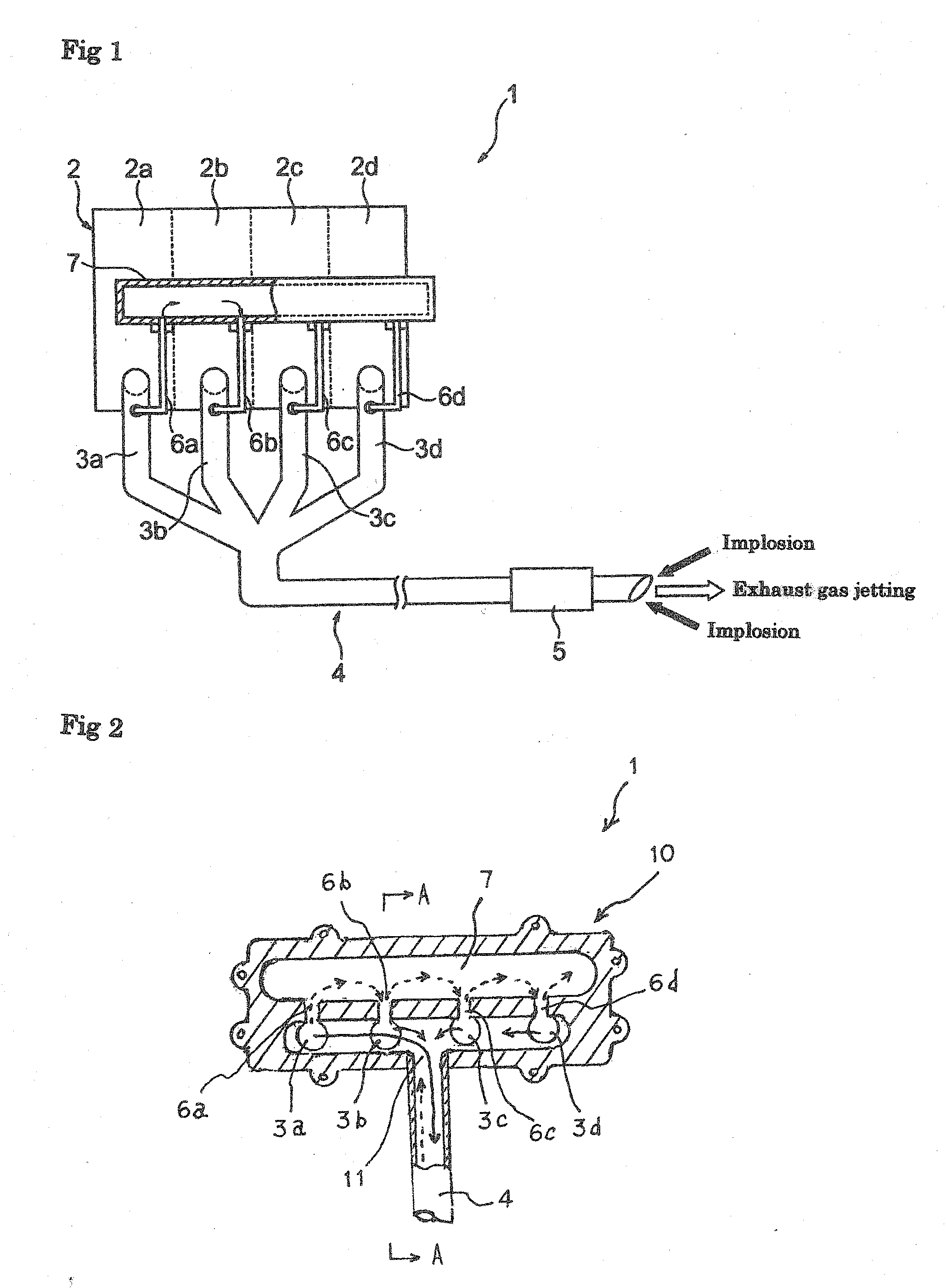

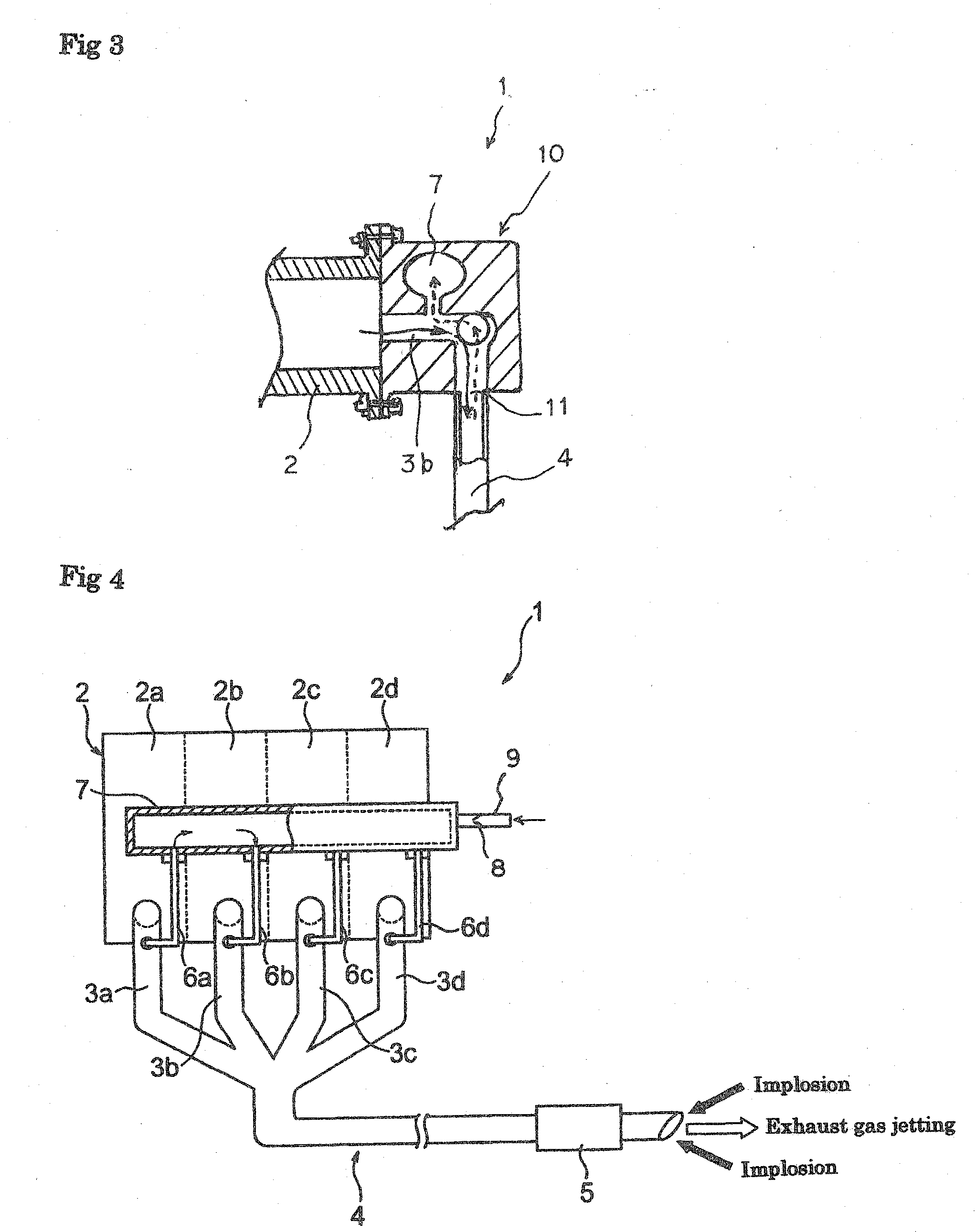

[0049]An air flow passage made of stainless steel with an inner diameter of ⅓ of the inner diameter for an exhaust tube was in communication with each of the cylinder exhaust tubes of the diesel passenger car and the other end of each of the air flow passages was in communication with the tightly closed hollow bypassing control chamber disposed separately to a frame near the engine to modify into a structure of the internal combustion engine of the example shown in FIG. 1.

[0050]The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com