Thin film transistor manufacturing method and substrate structure

a manufacturing method and substrate technology, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of low yield, inaccurate alignment, and difficult to change the way people used to read, so as to improve the efficiency of backlighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

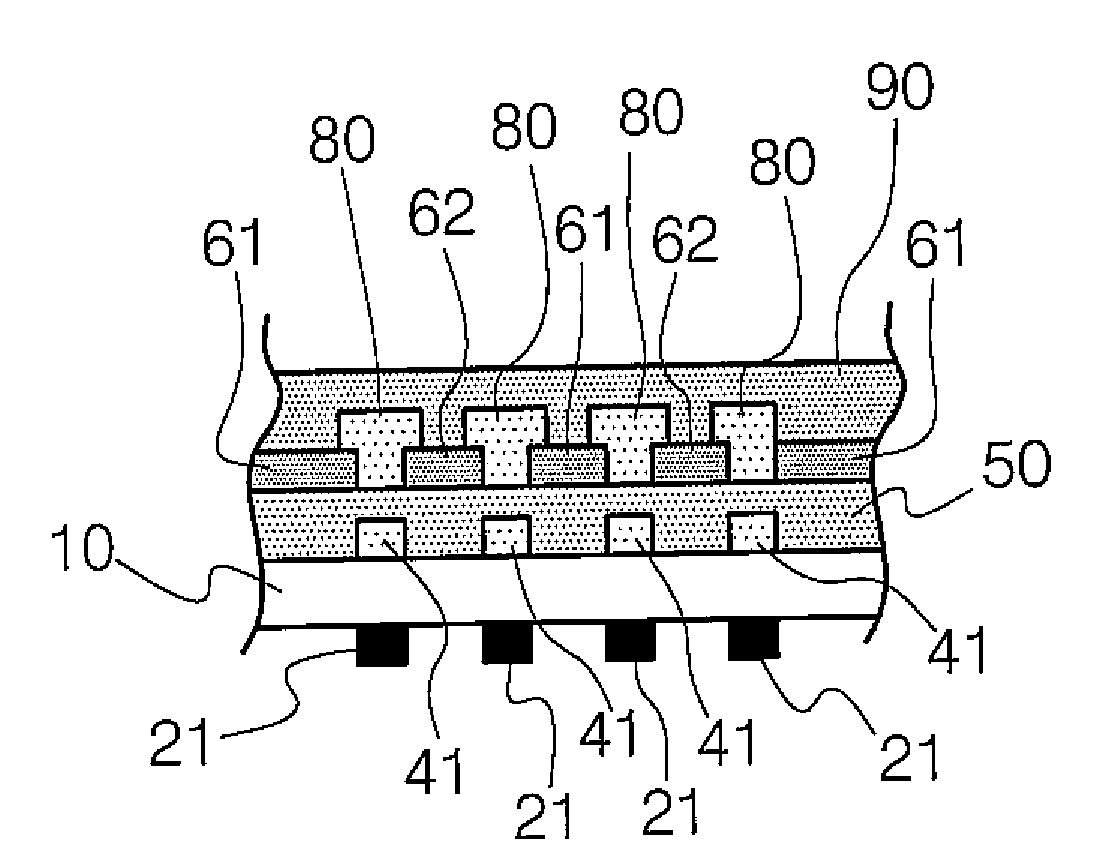

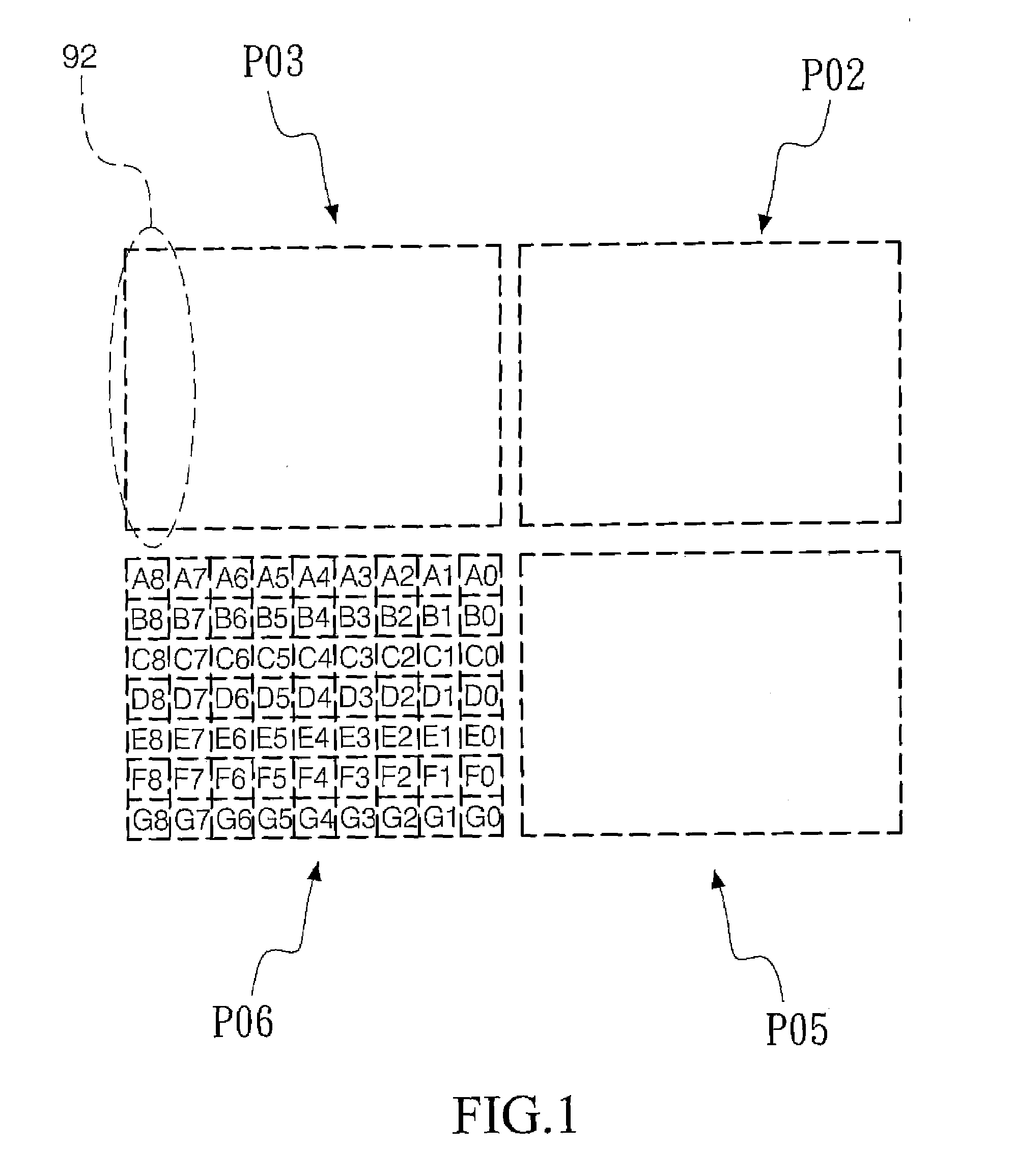

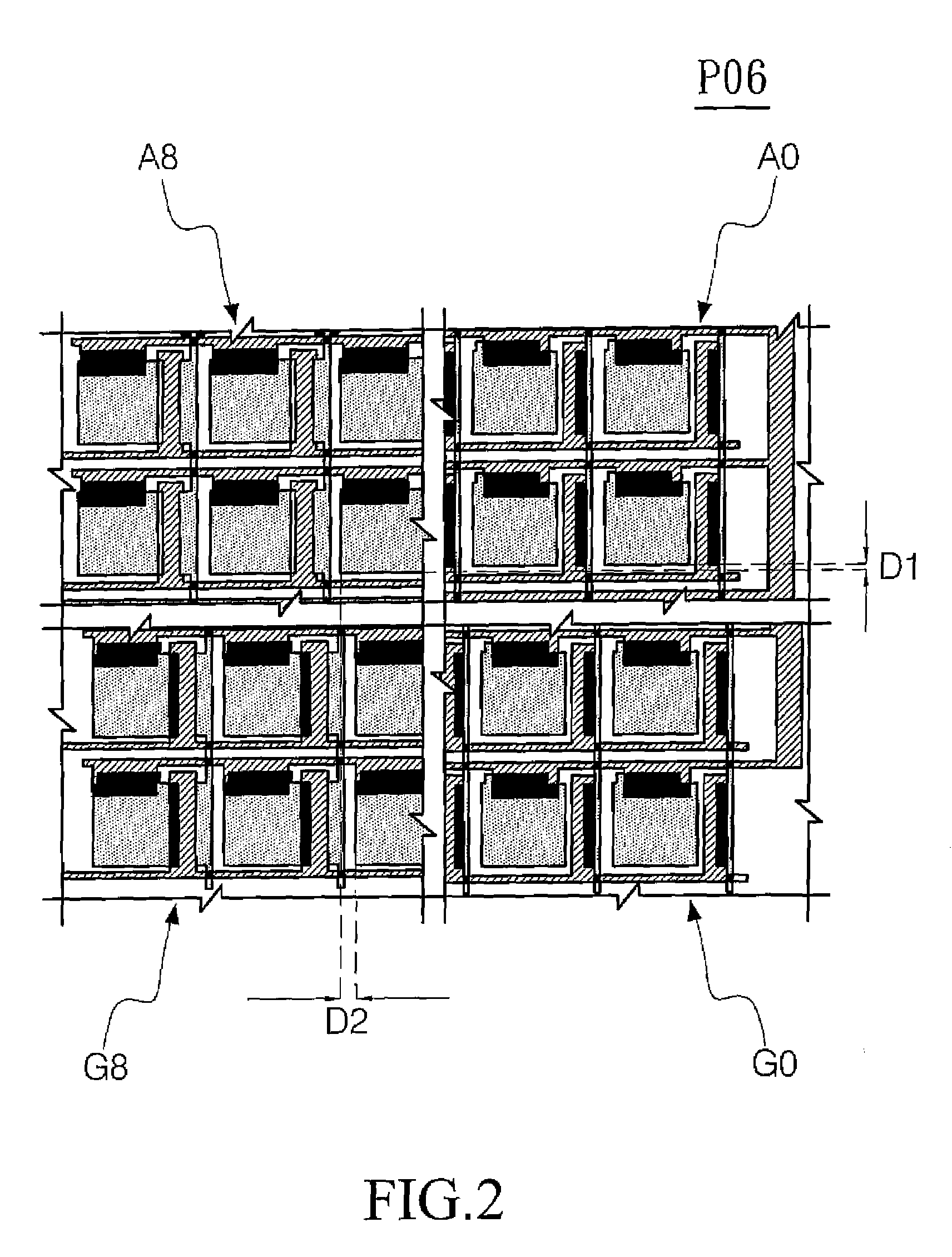

[0059]A TFT manufacturing method (M10) according to this embodiment is particularly suitable for a display having a backlight module. In order to enhance the backlight module's lighting efficiency, the TFT manufacturing method (M10) uses a first mask 21 which is complementary to the source 61 and the drain 62 of the TFT in position, measure of area and shape; and a negative type photo resist layer 70 to define the source 61 and the drain 62 of a TFT.

[0060]Please refer to FIG. 3A, which is a diagram showing a second surface of a substrate forming an opaque thin film thereon. In this embodiment, first provide a substrate 10 for manufacturing a TFT thereon. The substrate 10 has a first surface 11 and a second surface 12 on which is formed a transistor including a source 61, a drain 62, and a gate 41. Then the second surface 12, where no TFT forms, has an opaque thin film 20 forming thereon for manufacturing the first mask 21.

[0061]Please refer to FIG. 3B, which is a diagram showing a f...

second embodiment

[0067]A TFT manufacturing method (M20) according to this embodiment is particularly suitable for a reflective display. In order to increase the reflective area of the display, the TFT manufacturing method (M20) uses a second mask 22 which is the same with the source 61 and the drain 62 of the TFT in position, measure of area and shape; and a transparent gate 43 and a positive type photo resist layer 71 to define the source 61 and the drain 62 of a TFT.

[0068]Please refer to FIG. 5A, which is a diagram showing a second surface of a substrate forming an opaque thin film thereon. In this embodiment, first provide a substrate 10 for manufacturing a TFT thereon. The substrate 10 has a first surface 11 and a second surface 12. The first surface is used for forming a transistor including a source 61, a drain 62, and a transparent gate 43 formed thereon. Then the second surface 12, where not used to form TFT, has an opaque thin film 20 forming thereon for manufacturing the second mask 22.

[00...

third embodiment

[0075]A TFT manufacturing method (M30) according to this embodiment is particularly suitable for a display that has a backlight module. Like method M10, although this method is also for enhancing the backlight module's lighting efficiency, this method uses an opaque gate 45 as a gate electrode and a self-alignment mask for making the source 61 and the drain 62 at the same time. The opaque gate 45 works with a negative type photo resist layer 70 to define the source 61 and the drain 62 of a TFT.

[0076]Please refer to FIG. 7A, which is a diagram showing a first surface of a substrate forming an opaque gate thin film thereon. In this embodiment, first provide a substrate 10 for manufacturing a TFT thereon. Then an opaque gate thin film 44 is formed on one surface of the substrate 10.

[0077]Please refer to FIG. 7B, which is a diagram showing an opaque gate thin film processed to form the opaque gate by the photolithography process. First a photo resist layer 30 is formed on the opaque gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com