High strength and high ductility magnesium alloy and its preparation method

a high-ductility, magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of low ductility, and limiting the application of magnesium alloys, and achieves the effects of excellent specific strength, good damping capacity, and superior machinability and castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

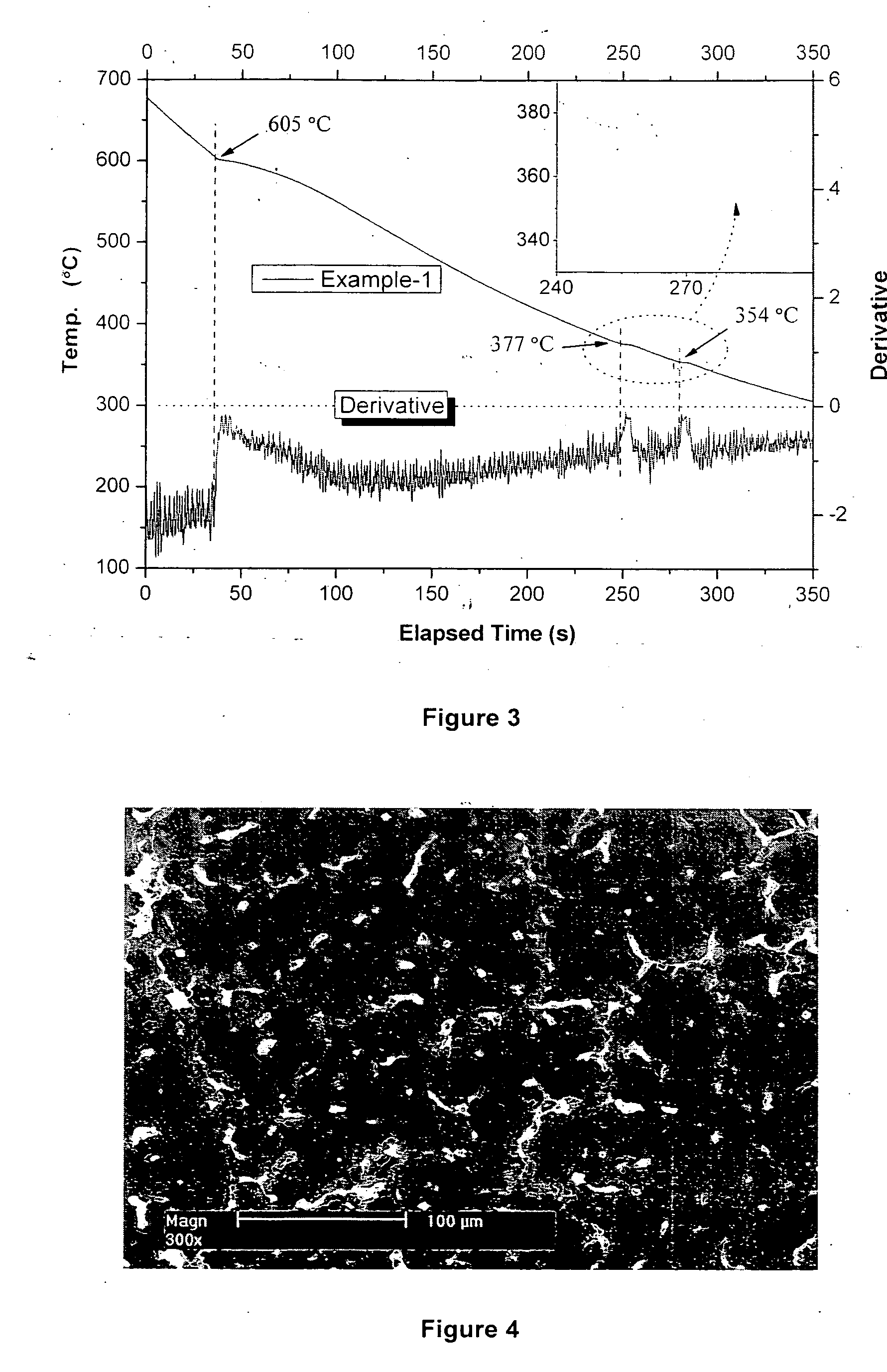

example-1

I) The Compositions

[0057]Three magnesium alloys were prepared in a mild steel crucible using commercial high-purity raw materials. Among them, commercial alloy AZ91 and AM60 acted as reference alloys. Chemical composition analyses of the three alloys were performed by inductively coupled plasma atomic emission spectroscopy (ICP-AES) and the chemical compositions are listed in Table 2.

TABLE 2The chemical composition of three alloys (wt %)AlloysAlZnMnSbMgAZ919.001.030.29—Bal.AM605.92—0.28—Bal.Example-15.883.890.300.51Bal.

[0058]The smelting was carried out in a resistance furnace and a crucible having a capacity of 15 kg. The crucible and the casting mold were made of mild steel. Taking Example-1 alloy as an example, the smelting and casting processes are described in detail as following:[0059]1) Set the temperature of the crucible to 720° C. and start heating. Preheat the raw material (pure magnesium, pure aluminum, Al—Mn master alloy, pure antimony, pure Z...

example-2

I) The Compositions

[0079]The chemical composition of Example-2 is listed in Table 4.

TABLE 4Alloys Composition of Example-2 (wt %)AlloysAlZnMnSbMgExample-26.165.080.310.48Bal.

[0080]Referring to the smelting and casting of Example-1. The difference mainly lies in the zinc content of the two alloys.

III) The Heat Treatments

[0081]Referring to the heat treatments of Example-1. The difference mainly lies in that the temperature of T4 temper was 360° C. according to the DTA analysis of Example-2, and the heating duration was 12 hours. The artificial ageing temperature of T5 temper was 180° C. and the duration was 16 hours.

IV) The Mechanical Properties

[0082]Referring to the tests of various mechanical properties of Example-1.

TABLE 5The room temperature mechanical properties of Example-2HeatYTSUTSElongationBrinellImpactTreatment(MPa)(MPa)(%)HardnessEnergy (J)As cast11021086315T6 temper14525067412

[0083]The comparison of 150° C. tensile property between Example-2 and...

example-3

I) The Compositions

[0084]The chemical composition of Example-3 is listed in Table 6.

TABLE 6Alloys Composition of Example-3 (wt %)AlloysAlZnMnSbMgExample-35.896.740.350.53Bal.

[0085]Referring to the smelting and casting of Example-1. The difference mainly lies in the zinc content of the two alloys.

III) The Heat Treatments

[0086]Referring to the heat treatments of Example-1. The difference mainly lies in that the temperature of T4 temper was 350° C. according to the DTA analysis of Example-3, and the heating duration was 12 hours. The artificial ageing temperature of T5 temper was 180° C. and the duration was 16 hours.

IV) The Mechanical Properties

[0087]Referring to the tests of various mechanical properties of Example-1.

TABLE 7The room temperature mechanical properties of Example-3HeatYTSUTSElongationBrinellImpactTreatment(MPa)(MPa)(%)HardnessEnergy (J)As cast1152026.56713T6 temper1532605779

[0088]The comparison of 150° C. tensile property between Example-3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com