Device and Method for the Quantity-Controlled Filling of Containers with Powdered Substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

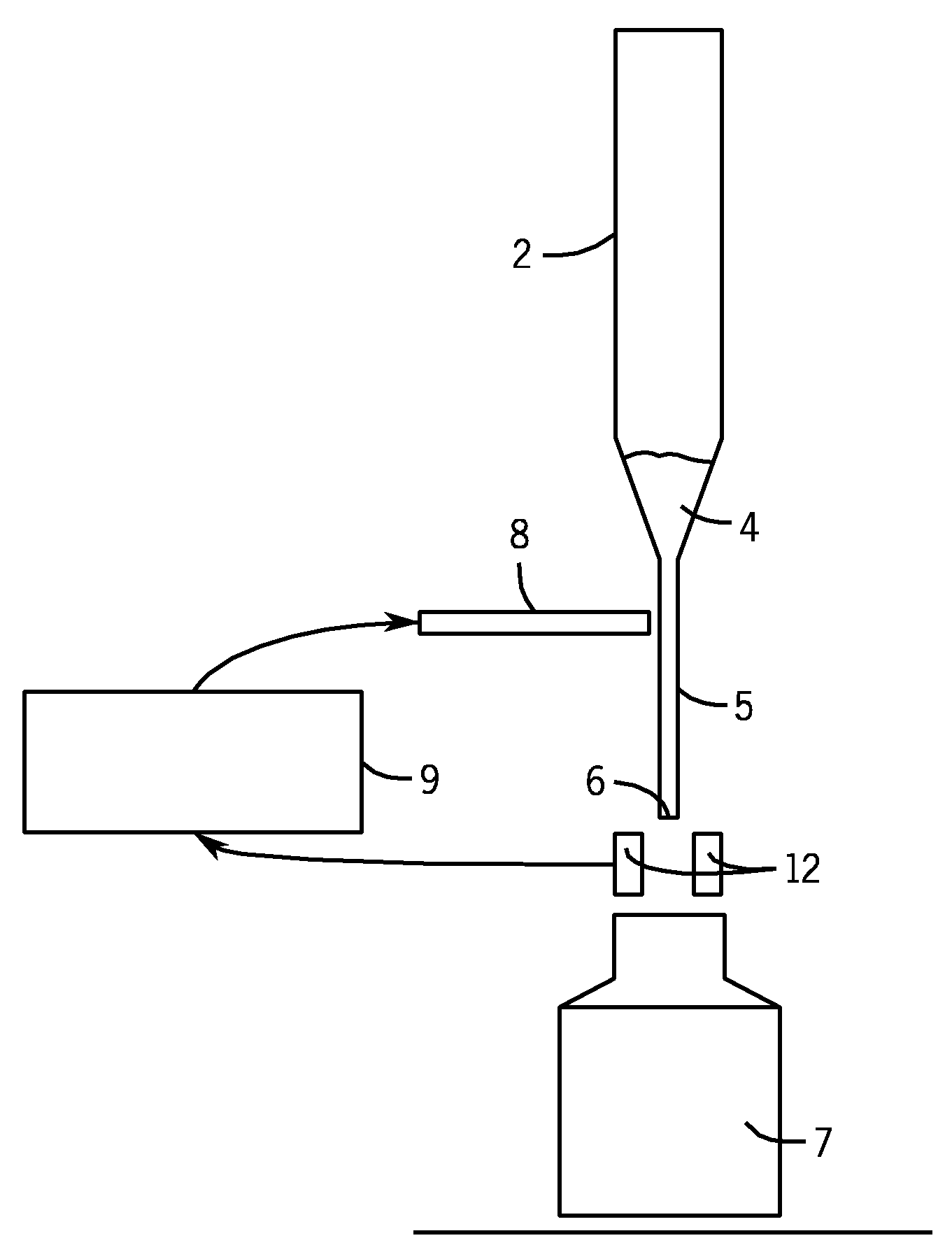

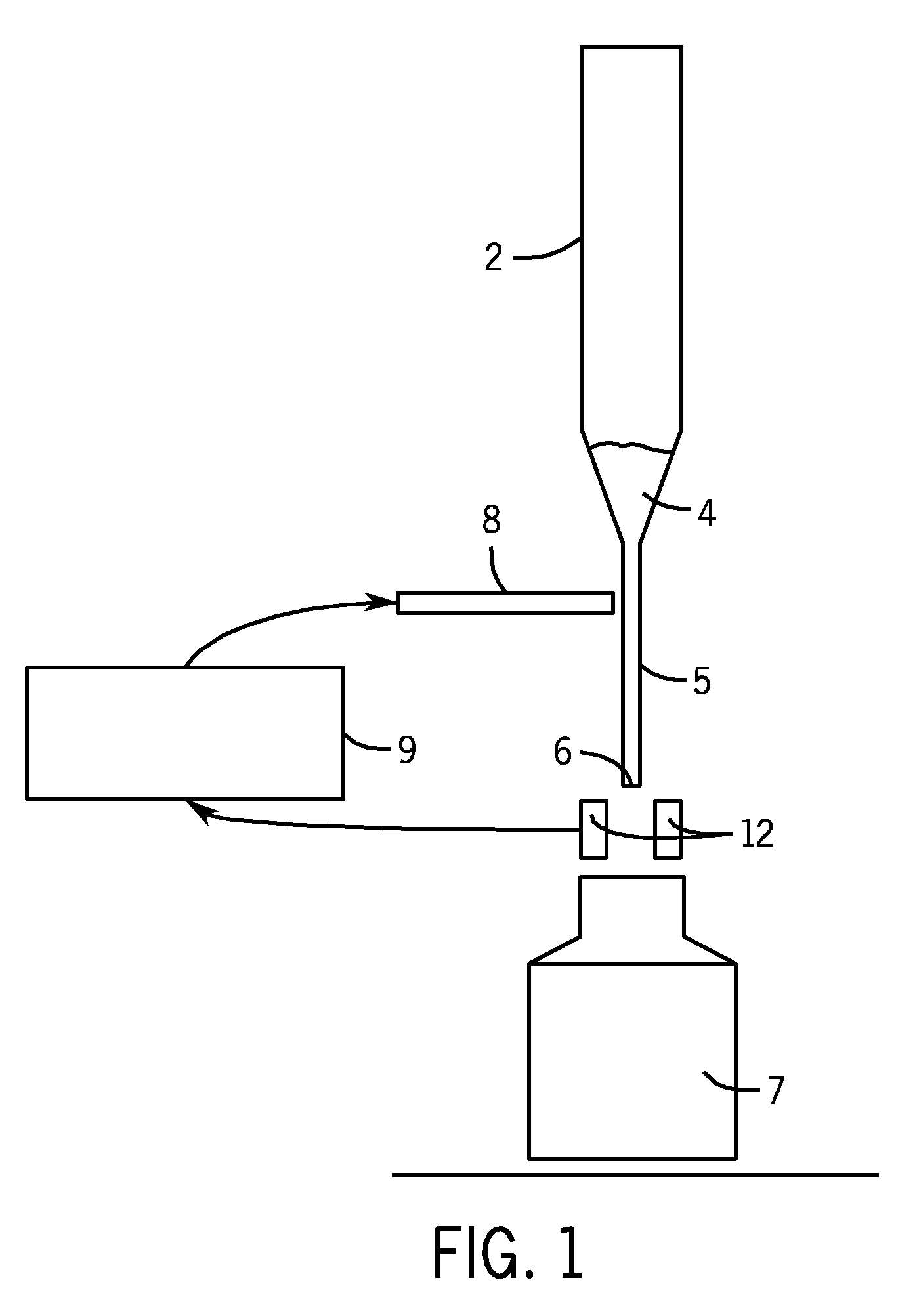

[0021]FIG. 1 is a schematic view of an exemplary embodiment of the inventive device for the controlled filling of containers with powdered substances. The device comprises a supply vessel 2, which is at least partially filled with a powdered substance 4. Supply vessel 2 is preferably clamped in a holder (not shown), which is mounted so that it is free to rotate. Supply vessel 2 is preferably made of high-grade steel, but many other materials such as glass, ceramic or other metals are which are also contemplated herein. In a preferred embodiment shown in FIG. 1, supply vessel 2 comprises at its lower end a capillary 5, which tapers to a point at the bottom, where a narrow exit opening 6 is located. The length and diameter of capillary 5 can be adapted to powdered substance 4 and to the geometry of the container 7 to be filled. Supply vessel 2 can also be of a two-part design in order to make it easier to replace capillary 5 with one of a different size, material, configuration or the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com