Method For Use Of A Double-Structured Tissue Implant For Treatment Of Tissue Defects

a tissue implant and double-structure technology, applied in the field of tissue implant use, can solve the problems of uneven and uncontrolled porosity, difficult handling of structures, and many of the above disclosed structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

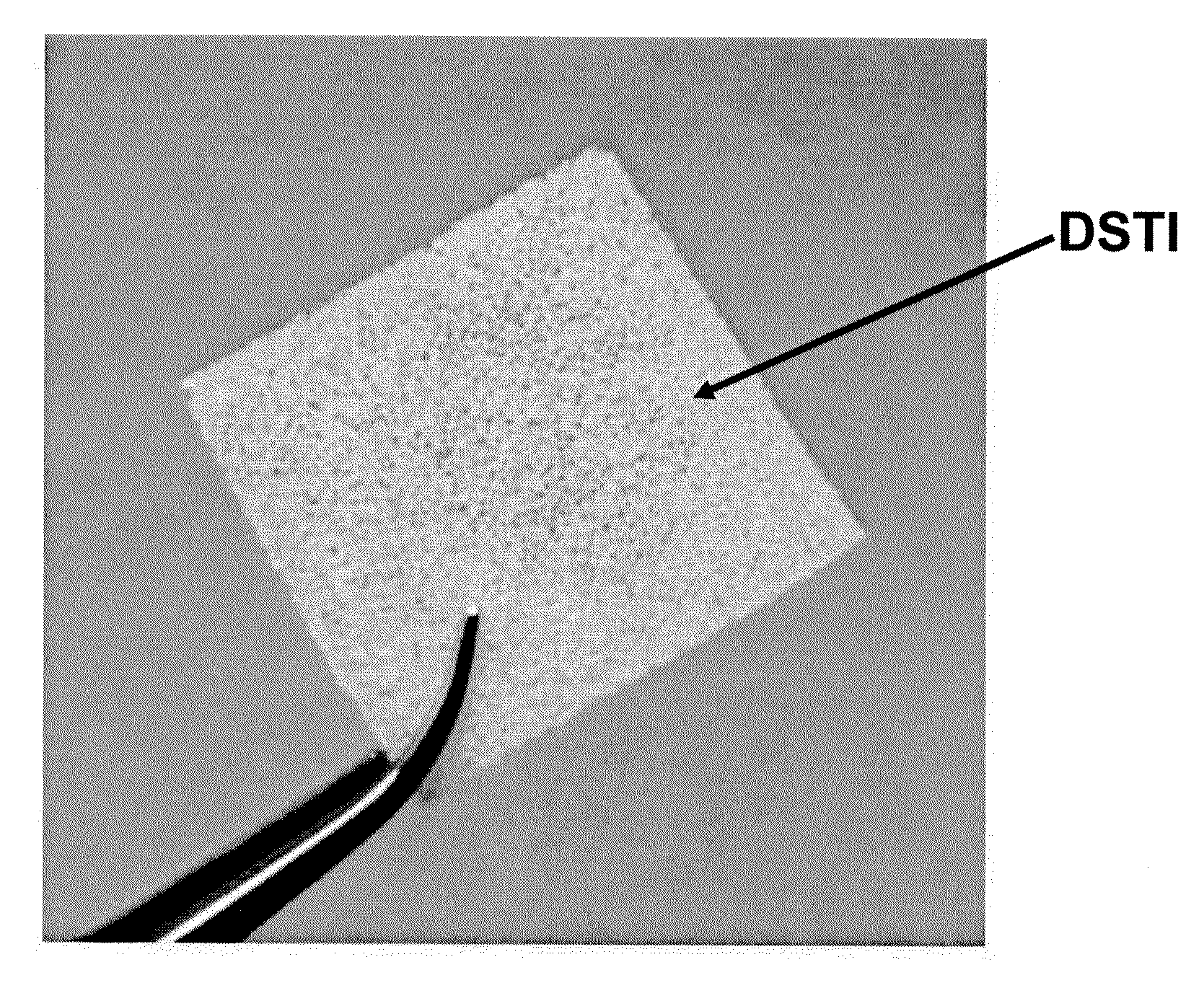

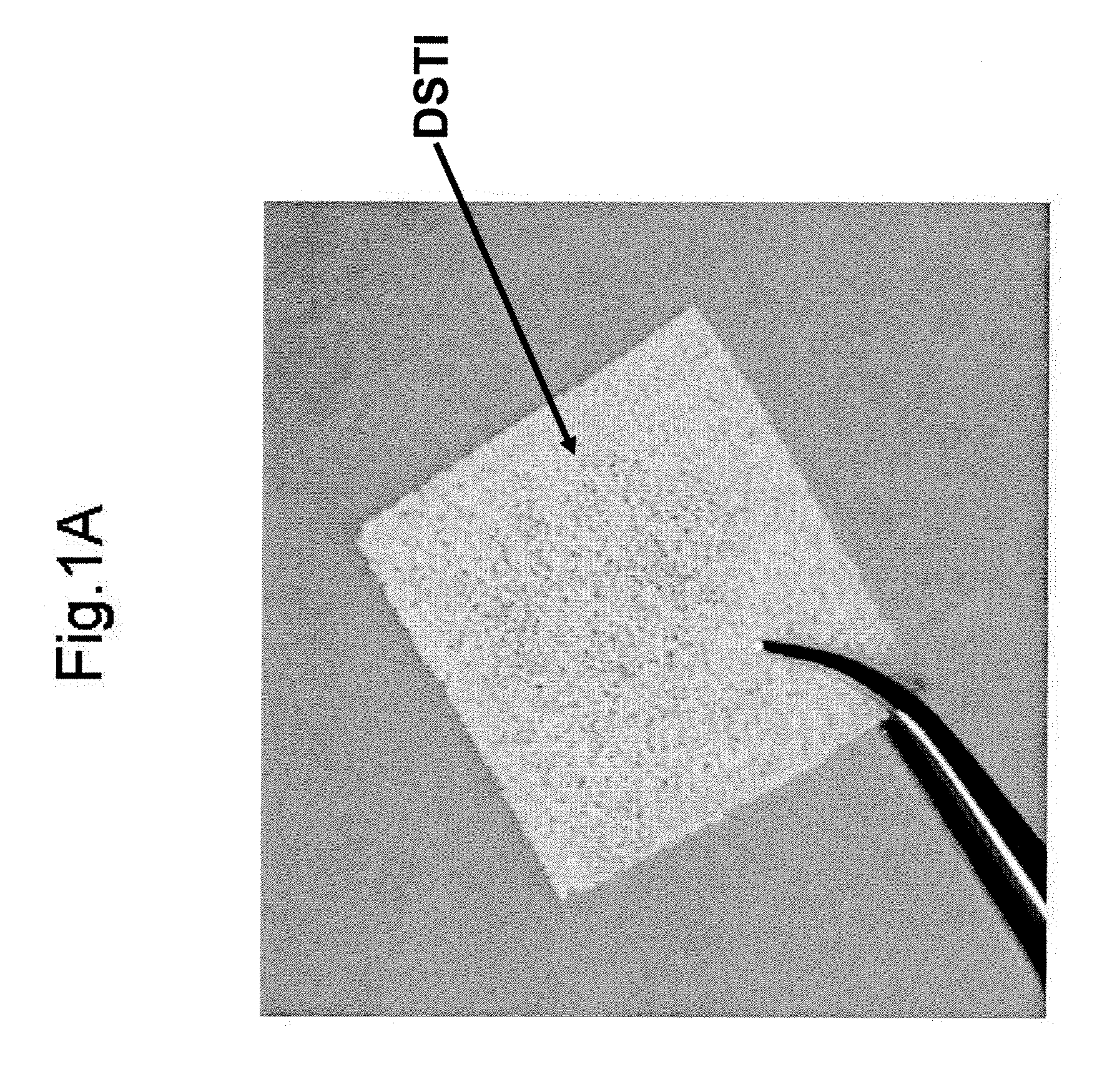

Image

Examples

example 1

Preparation of the Primary Scaffold

[0252]This example describes one exemplary method for preparation of the collagen-based primary scaffold suitable as a structural support for preparation of the DSTI. Type I collagen is dissolved in a weak hydrochloric acid solution at pH 3.0 with the collagen concentration and osmolality of the solution adjusted to about 3.5 mg / ml and 20 mOsm / kg, respectively. The solution (70 ml) is poured into a 100 ml Petri dish and the Petri dish containing the collagen solution is centrifuged at 400×g for 30 minutes to remove air bubbles. Neutralization and subsequent precipitation or gelling is carried out in a 7 liter chamber containing 10 ml of 15% ammonia solution over a 45 minutes period. The precipitated collagen is then washed in a large excess of de-ionized water. The water is changed as many times as needed over next 3 days to remove formed salts and excess ammonia.

[0253]The solution is then subjected to unidirectional freezing over a period of about...

example 2

Preparation of a Basic Solution for a Secondary Scaffold

[0255]This example describes preparation of the Basic Solution used for formation of the secondary scaffold. The Basic Solution comprises a soluble collagen in admixture with a PLURONIC® surfactant. The Basic Solution is incorporated into the primary scaffold and processes into the double scaffold tissue implant or processed as a stand alone implant.

[0256]Solution for the secondary scaffold is prepared by mixing PLURONIC® F127 (2.32 mg, 0.29 mg / ml), obtained commercially from BASF, Germany, with 8 ml of a solution containing 2.9 mg / ml bovine type I collagen dissolved in hydrochloric acid (pH 2.0) at room temperature. The resulting solution is neutralized with 1 ml of 10× Dulbecco=s phosphate buffered saline (DPBS) and 1 ml of 0.1M NaOH to the final pH of 7.4.

[0257]In the alternative, the neutralization is achieved by ammonia aqueous solution or ammonia vapor in concentration sufficient to neutralize acid within the collagen sol...

example 3

Preparation of the Secondary Scaffold as Stand Alone Unit

[0258]This example illustrates preparation of the secondary scaffold as a stand alone implant or stand alone unit. For preparation of the stand alone secondary scaffold, the Basic Solution prepared in Example 3 is subjected to precipitation or gelling followed by dehydrothermal treatment.

[0259]The Basic Solution (2 ml) comprising collagen and PLURONIC® surfactant is placed in a small glass beaker and the beaker is placed into a chamber (approximately 9 liters) charged with 1% ammonia solution. The Basic Solution is allowed to precipitate in the chamber over a period of 15 minutes. The gelled or precipitated collagen is then washed in 500 ml of deionized water over a period of 30 minutes. The washing step is repeated three times. The washed gel or precipitate is placed on metal shelf of a freezer at −80° C. over a period of 30 minutes. The frozen gel or precipitate is removed from the freezer and lyophilized. Lyophilization is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com