Treated substrate having hydrophilic region and water repellent region, and process for producing it

a technology of hydrophilic region and treated substrate, which is applied in the direction of instruments, photomechanical devices, synthetic resin layered products, etc., can solve the problems of high cost of facilities, low utilization efficiency of energy, materials, etc., and complex photolithography processes. , to achieve the effect of simple apparatus, high contrast on the surface can, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Substrate Wash

[0089]A 5 cm2 silicon wafer was washed with ethanol and then washed with UV / O3.

Preparation of a Coating Solution

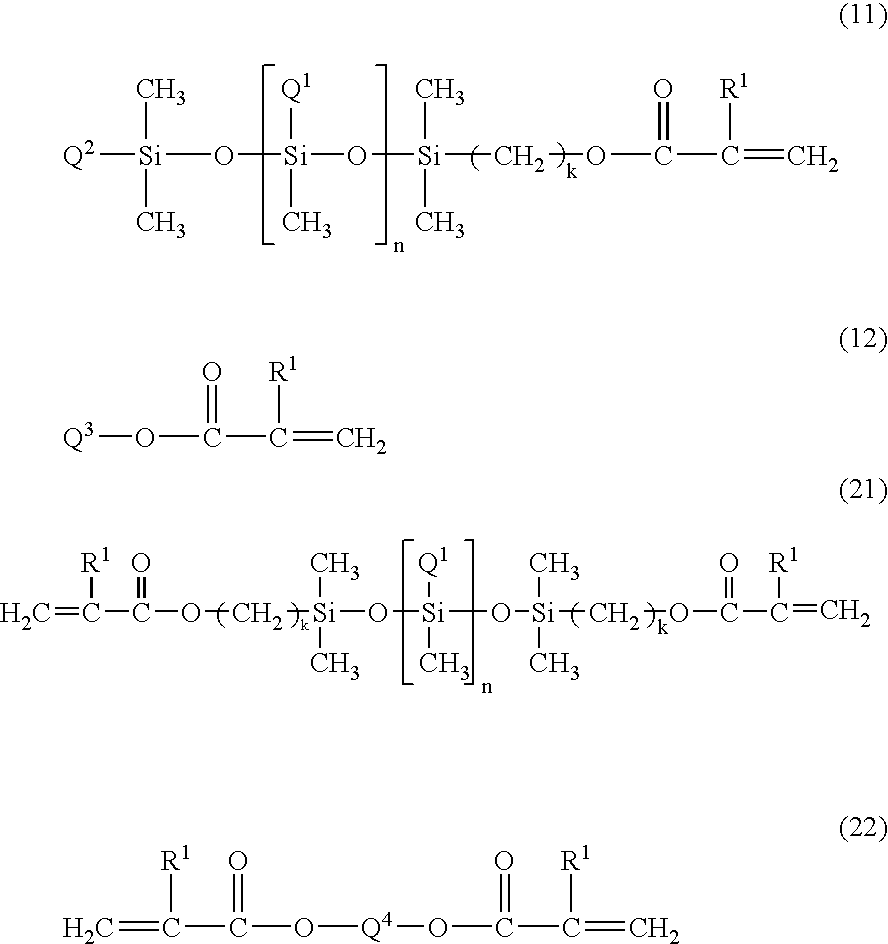

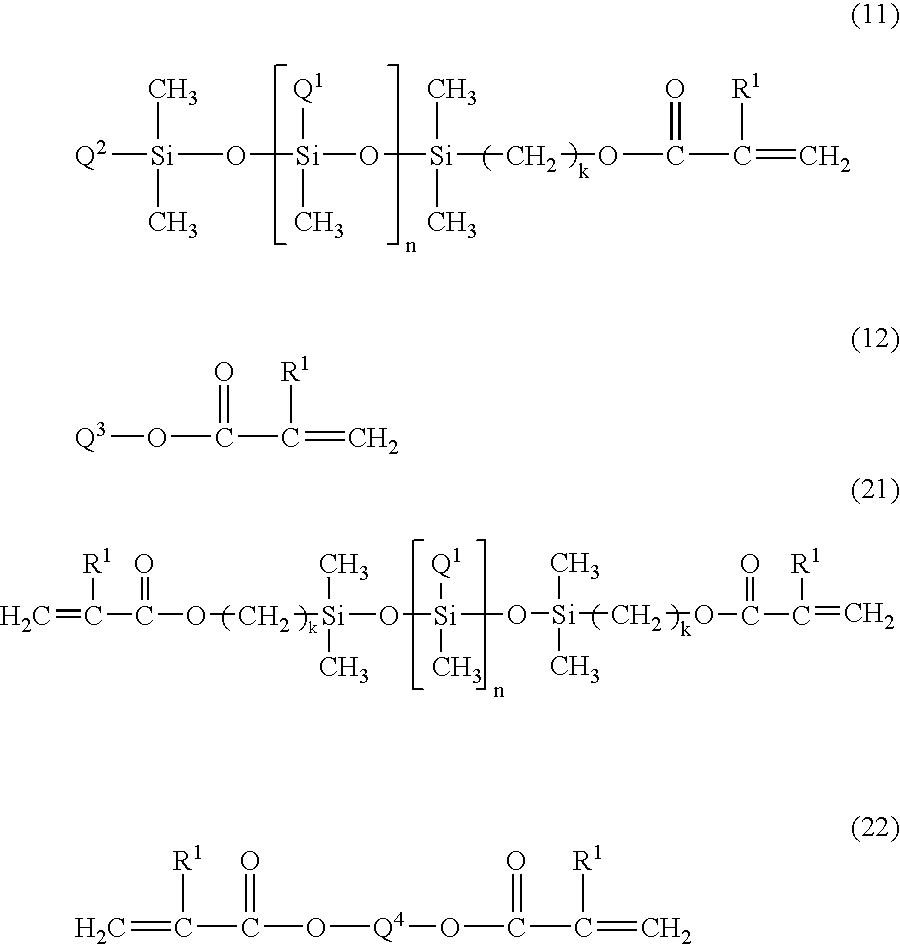

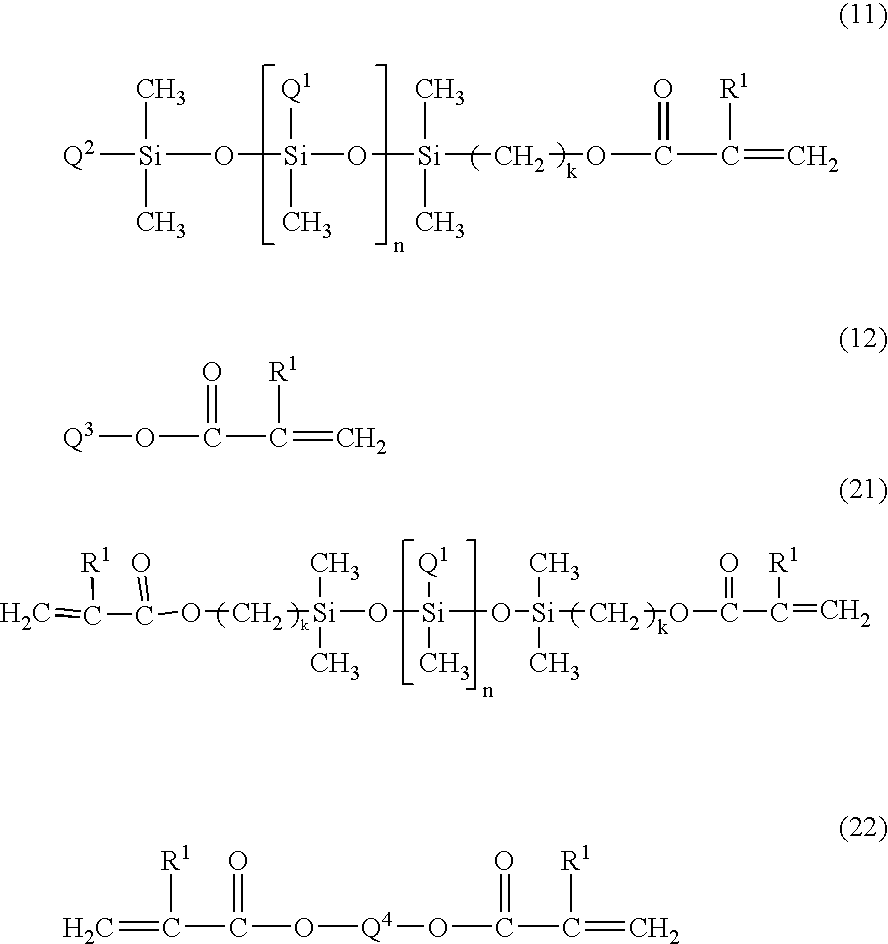

[0090]2.5 g of isopropanol was added in a sample vessel. 0.1 g of a 10 mass % isopropanol solution of a polydimethyl siloxane having methacryloyloxy propyl groups at both terminals (DMS-R18, manufactured by Gelest, Inc., the compound of the formula (21) wherein R1 is a methyl group, Q1 is a methyl group, k is 3, and the molecular weight is from 4,500 to 5,500) was added to the sample vessel. 0.2 g of a 1 mass % isopropanol solution of trimethylol propane triacrylate was added. 0.06 g of a 1% isopropanol solution of IRGACURE 369 (manufactured by CIBA-GEIGY Limited) was added as a photopolymerization initiator. The sample vessel was shaken a few times to mix the solution.

Coating with a Solution

[0091]The silicon wafer was coated with the prepared coating solution by spin coating under a condition of 3000 rpm for 20 seconds, and a film was formed.

Light Irradiatio...

example 2

[0096]The same operation was carried out as in Example 1, except that IRAGARACURE 907 (manufactured by CIBA-GEIGY Limited) was used, instead of IRAGARACURE 369. The thickness of the obtained film was 8 nm.

[0097]The contact angle to water of the obtained treated substrate was 21° at a non-irradiated part and 100° at an ultraviolet light irradiated part. Therefore, a water repellent-hydrophilic pattern having a hydrophilic region (contact angle: 21°) and a water repellent region (contact angle: 100°) was confirmed.

example 3

[0098]The same operation was carried out as in Example 2, except that 0.5 g of a 1% aqueous solution of a polyvinyl alcohol (molecular weight: 500, manufactured by KANTO CHEMICAL CO., INC.) was added to a coating solution, and after spin coating, the substrate was left to stand still for 5 minutes. The thickness of the obtained film is estimated to be about 12 nm.

[0099]The contact angle to water of the obtained treated substrate was 29° at a non-irradiated part and 100° at an ultraviolet light irradiated part. Therefore, a water repellent-hydrophilic pattern having a hydrophilic region (contact angle: 29°) and a water repellent region (contact angle: 100°) was confirmed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com