Ballistic Fabric

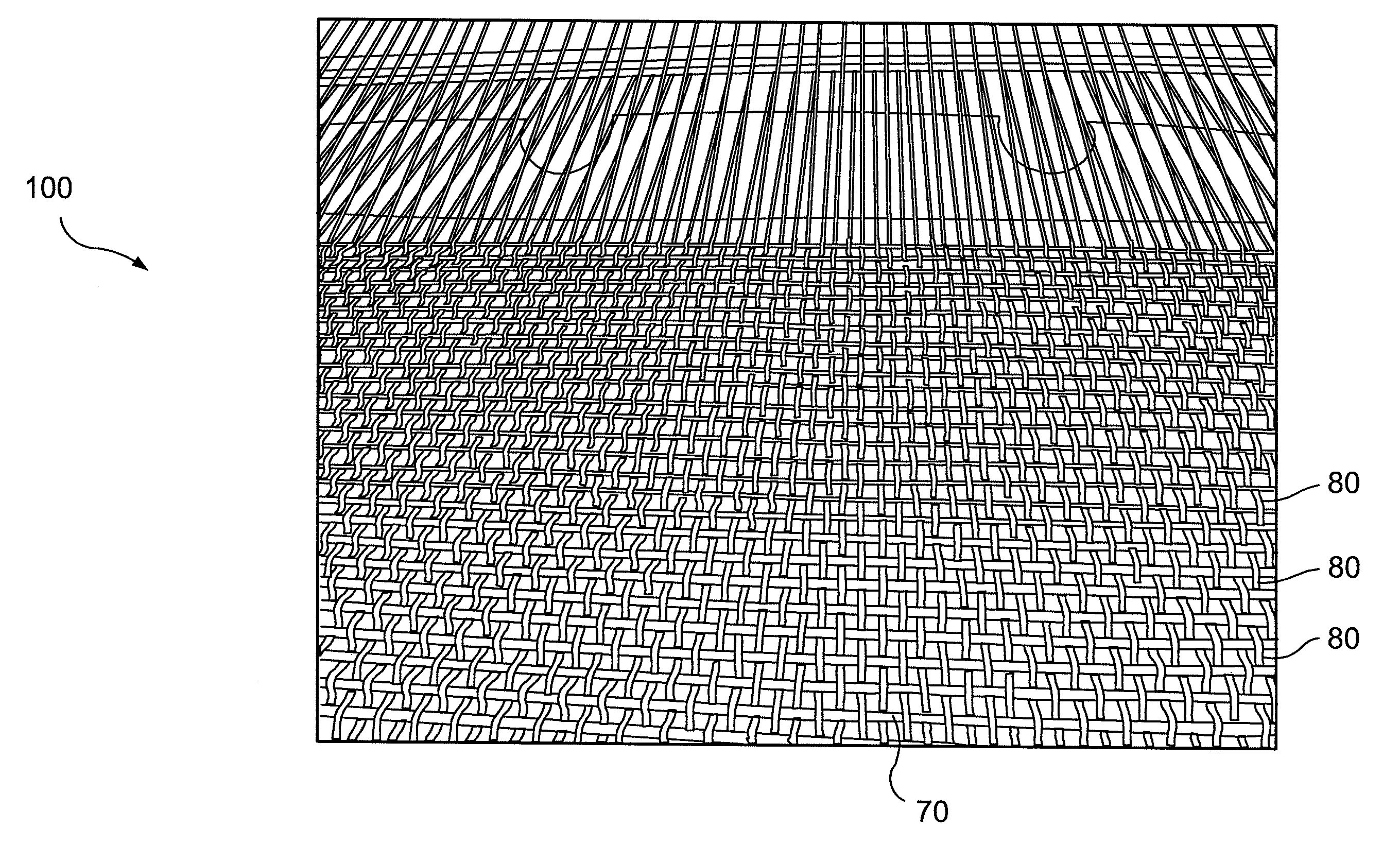

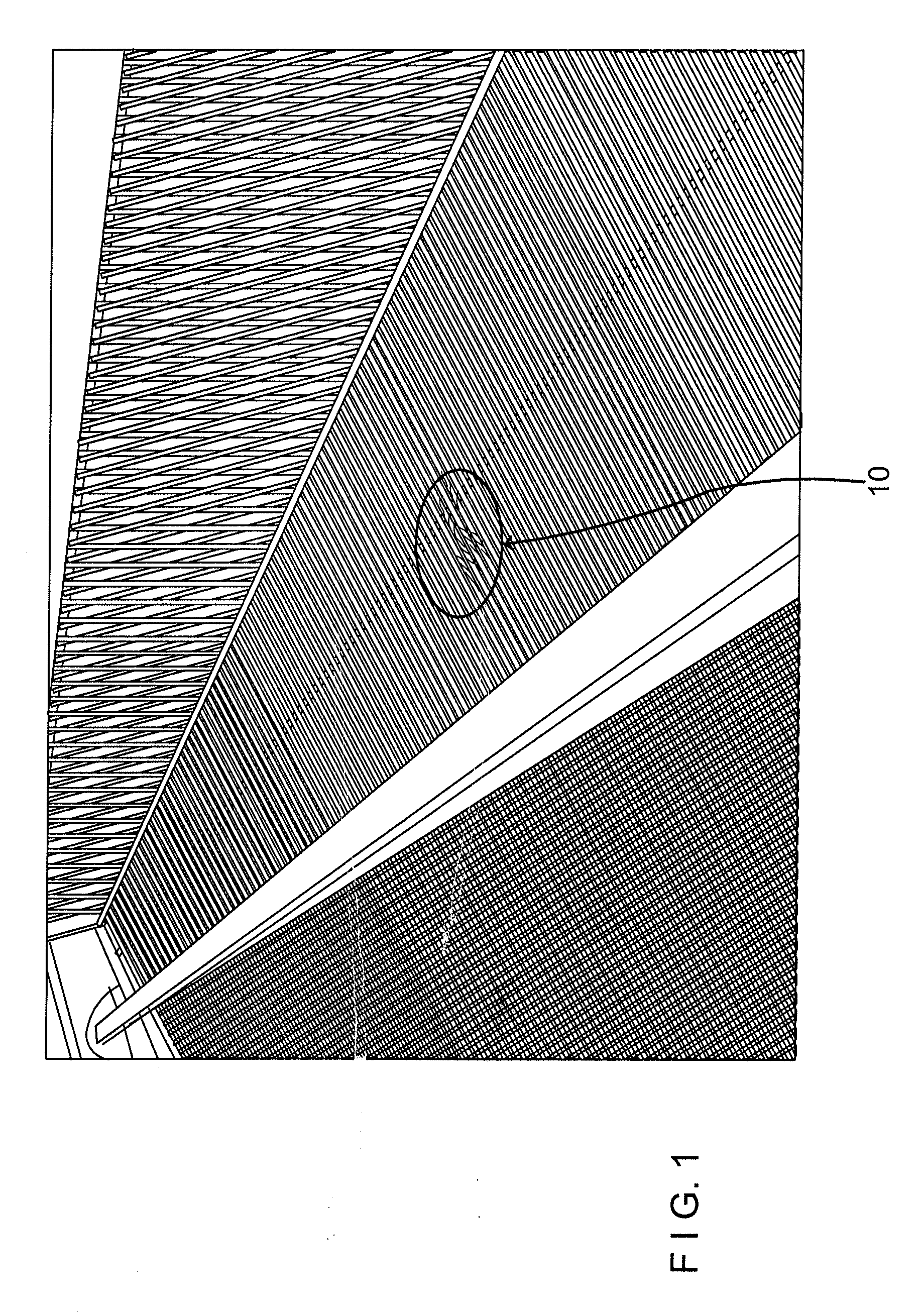

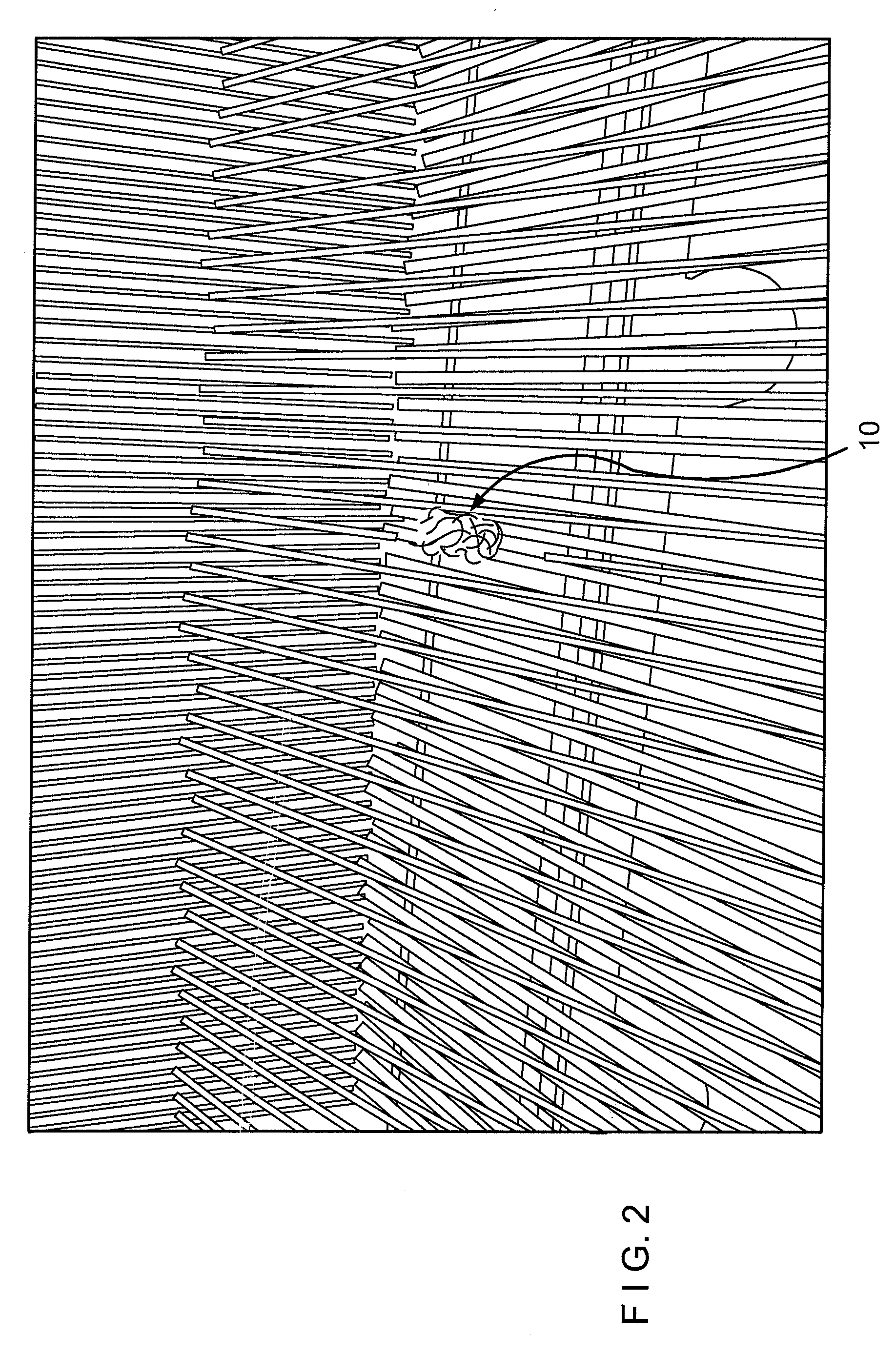

a technology of fabric and ballistics, applied in protective fabrics, shutters/movable grilles, weaving, etc., can solve the problems of plant or house collapse, huge and deadly storms, and people within the building being injured or killed by flying glass, etc., to improve ballistic properties, less impact deformation, and additional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]It is noted that in this disclosure and particularly in the claims and / or paragraphs, terms such as “comprises,”“comprised,”“comprising,” and the like can have the meaning attributed to it in U.S. patent law; that is, they can mean “includes,”“included,”“including,”“including, but not limited to” and the like, and allow for elements not explicitly recited. Terms such as “consisting essentially of” and “consists essentially of” have the meaning ascribed to them in U.S. patent law; that is, they allow for elements not explicitly recited, but exclude elements that are found in the prior art or that affect a basic or novel characteristic of the invention. These and other embodiments are disclosed or are apparent from and encompassed by, the following description.

[0033]Aramid based ballistic cloth / fabric have a well established application as a protective barrier (bullet proof vests, military vehicle body armor, aircraft engine containment, etc.) and therefore may be used in this a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| widths | aaaaa | aaaaa |

| wide width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com