Noncircular transient fluid fuel injector control channels in propellant injector combustion systems

a control channel and propellant injection technology, applied in the direction of gas turbine plants, hot gas positive displacement engine plants, intermittent jet plants, etc., can solve the problems of affecting and contaminating spacecraft surfaces. , to achieve the effect of improving the efficiency of bipropellant combustion systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

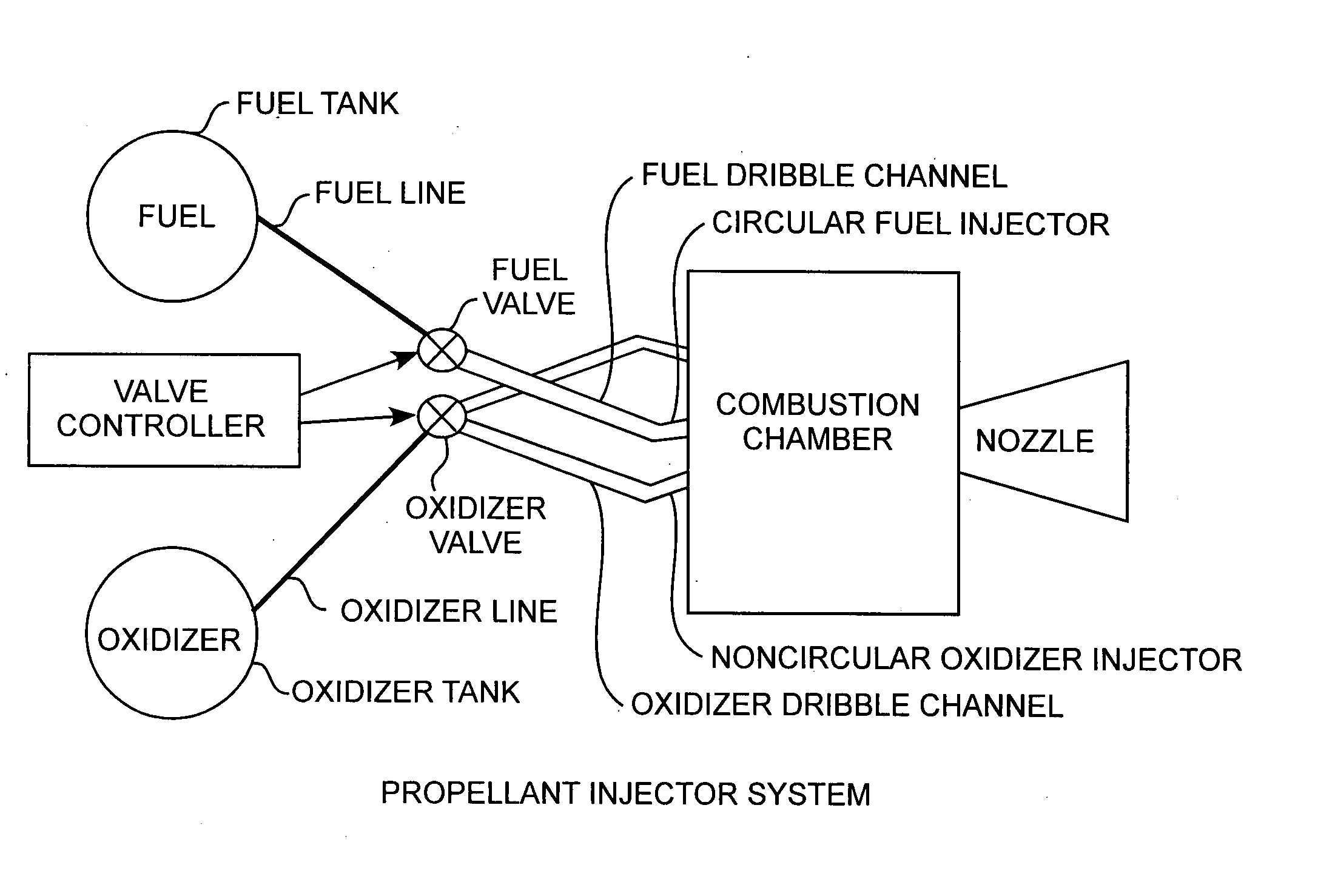

[0019]An embodiment of the invention is described with reference to the figures using reference designations as shown in the figures. Referring to FIG. 1, a fuel tank is used to store and contain liquid fuel and pressurant gas. A fuel line extends from the fuel tank to a fuel valve for controlling fuel flow from the fuel line into a fuel dribble channel. The dribble channel, in the preferred form, is a circular fuel channel connected between the fuel valve and a combustion chamber. The fuel passes from the tank to combustion chamber as limited by the fuel valve, the fuel dribble channel, and fuel injector. In the preferred form, the fuel injector is circular fuel injector orifice. A valve controller controls the fuel valve to control the flow of fuel from the fuel tank to the combustion chamber under system controls. The injector orifice, that is the circular fuel injector, is the last portion of the fuel line extending between the fuel valve and the combustion chamber. The last por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com