Process and apparatus for organic vapor jet deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

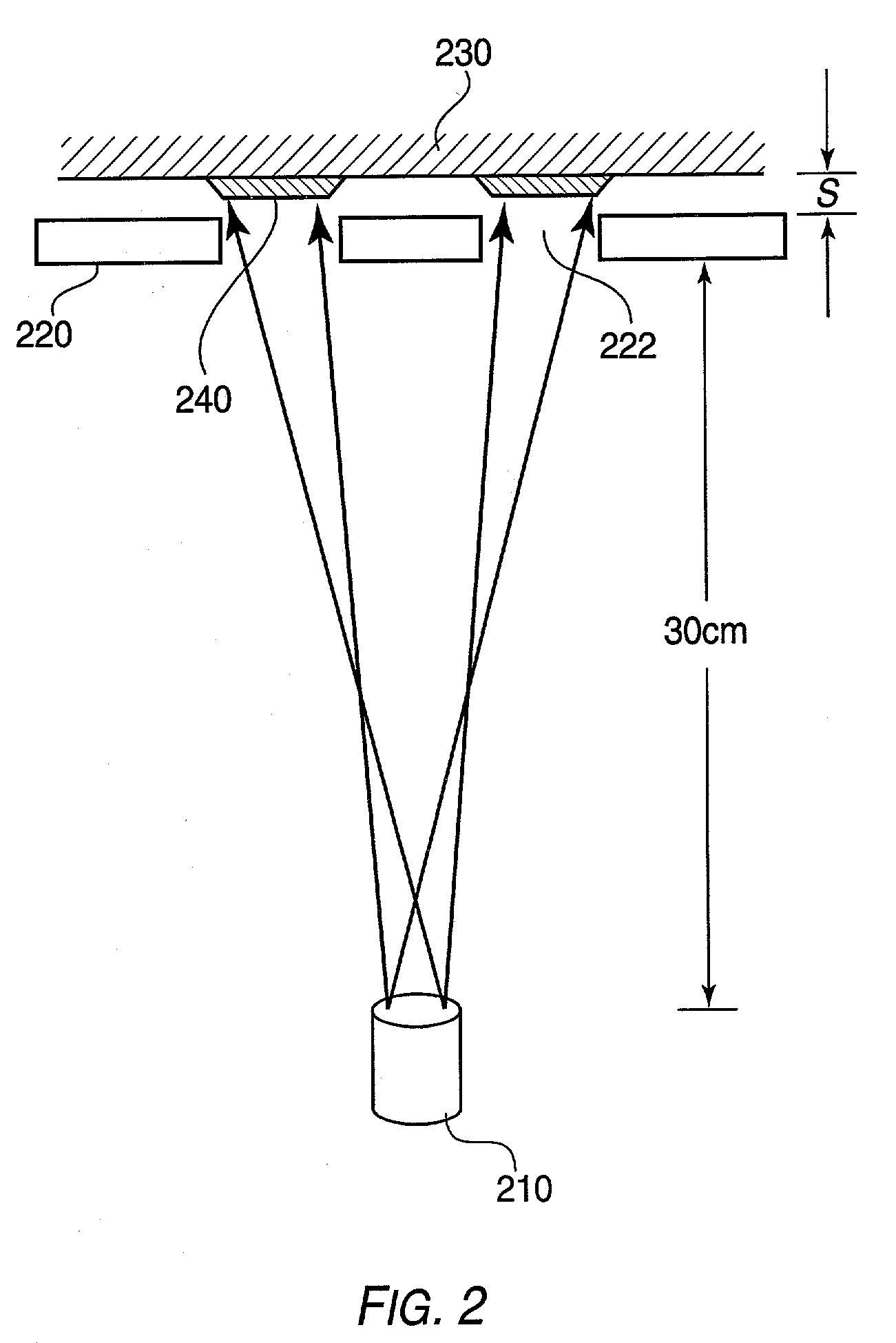

[0039]Embodiments of the present invention are directed to a process of patterned deposition of organic materials onto substrates utilizing the vapor transport mechanisms of organic vapor phase deposition, and to an apparatus for performing this process of patterned deposition. In one embodiment, the process comprises: transporting organic vapors via an inert carrier gas moving at a flowrate V from a source cell, through a timed valve, and into a nozzle block, wherein the transport occurs at low pressure P; ejecting the organic vapors from the nozzle block onto a cooled substrate via the inert carrier gas moving at a flowrate V; and laterally translating the cooled substrate, which is maintained at a distance s from the ejection end of the nozzle block, at a rate v. The rate of translation is synchronized with the timed valve to create the desired patterned deposition of organic materials.

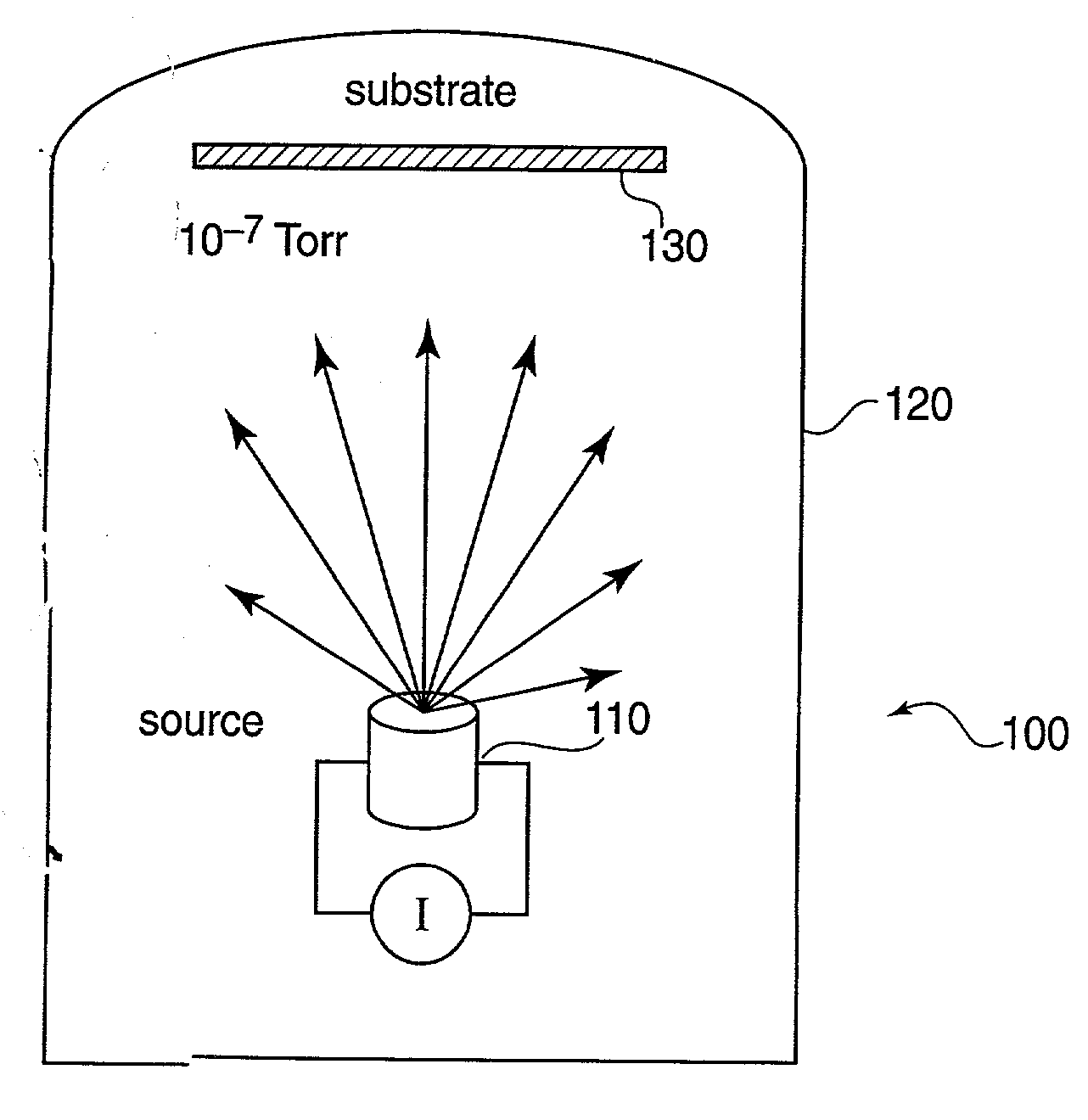

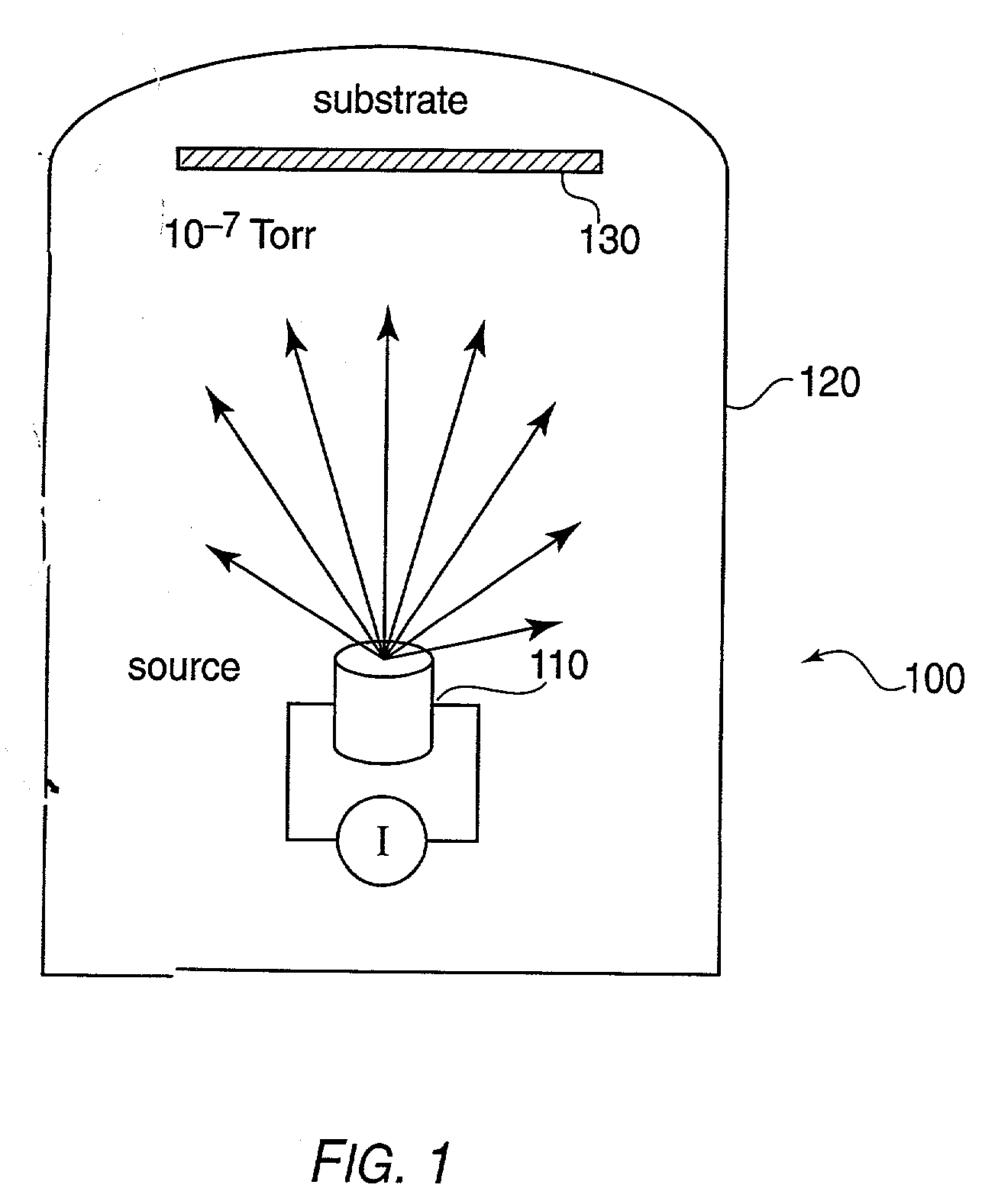

[0040]FIG. 1 shows a vacuum thermal evaporation (VTE) system 100. A source 110 is heated such t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com